Evaporator synergistic anti-frost device and method of use thereof

An evaporator and anti-frost technology, which is applied in the direction of evaporator/condenser, damage protection, refrigeration components, etc., can solve the problems of abnormal use, low efficiency, loss of heat exchange function of the evaporator, etc., to prevent frosting Ice, improve heat transfer efficiency, and complete heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

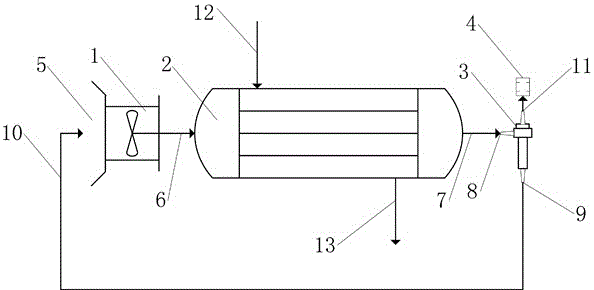

[0017] In this example, refer to figure 1 As shown, an evaporator synergistic anti-frost device includes a closed evaporator 2, a heat medium inlet 12 arranged on one side of the closed evaporator 2, and a heat medium inlet 12 arranged on the other side of the closed evaporator 2. Media outlet 13, and the high-pressure air inlet 6 that is arranged on the left side of the closed evaporator 2, and the high-pressure blower 1 connected with the high-pressure air inlet 6, and the ambient air inlet 5 that is arranged on the left side of the high-pressure blower 1, and is arranged on the closed The high-pressure air outlet 7 on the right side of the type evaporator 2, and the vortex tube inlet 8 connected with the high-pressure air outlet 7, and the vortex tube 3 connected with the vortex tube inlet 8, and the vortex tube cold air outlet arranged on one end of the vortex tube 3 11, and the silencer 4 that is connected with the vortex tube cold air outlet 11, and the vortex tube hot g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com