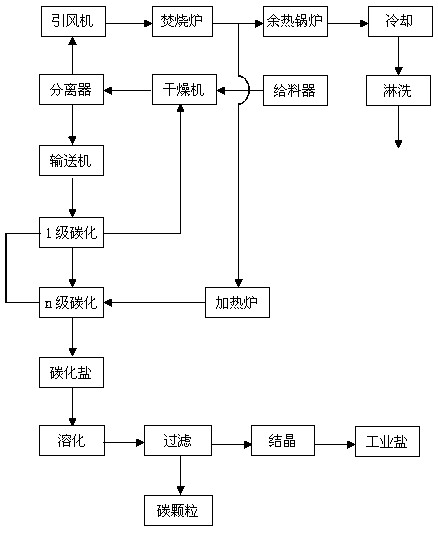

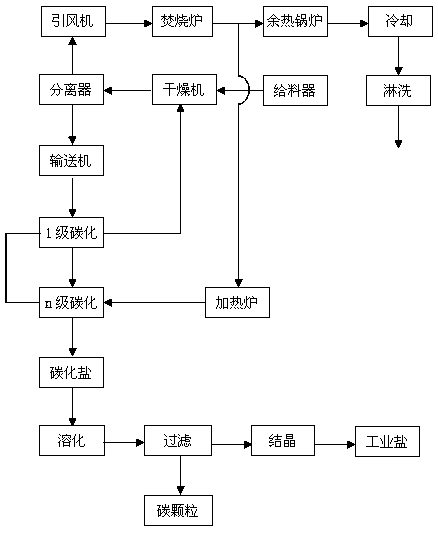

A process and equipment for industrial waste salt grading decomposition carbonization and harmless treatment

A technology for harmless treatment and industrial waste salt, which is applied in the chemical industry, carbon preparation/purification, solid waste removal, etc. and other problems, to achieve the effect of being conducive to decomposition and carbonization, reasonable and controllable heating process, and complete decomposition and carbonization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The industrial waste salt graded decomposition carbonization harmless treatment process of this embodiment is carried out according to the following steps:

[0042] (1) Take 1000kg of by-product industrial waste salt from a pesticide production enterprise. The measured sodium chloride content is 85.3%, water content is 13.6%, organic matter is 0.94%, and other substances are 0.16%. The drying temperature is 200°C. The dry tail gas is separated from gas and solid by the separator and then enters the incinerator for harmless treatment through the induced draft fan. The hot gas generated by incineration is supplemented by the heating furnace of the carbonization system, and the excess hot gas is recycled and cooled by the waste heat boiler. , Empty after rinsing.

[0043] (2) The dried industrial waste salt is discharged from the separator, and then enters the decomposition and carbonization furnaces at various levels for graded decomposition and carbonization. The tempera...

Embodiment 2

[0046] The process of the graded decomposition carbonization and harmless treatment of industrial waste salt in this embodiment is carried out according to the following steps:

[0047] (1) Take 1000kg of industrial waste salt material from a chemical company. After testing: the sodium chloride content is 94.1%, the water content is 5.4%, the organic matter is 0.3%, and other substances are 0.2%. It is sent to the dryer for drying through the feeder. The drying temperature The temperature is 190°C. The dry tail gas is separated from the gas and solid by the separator and then enters the incinerator for harmless treatment through the induced draft fan. The hot gas generated by incineration is supplemented by the heating furnace of the carbonization system. Drain after rinsing.

[0048] (2) The dried industrial waste salt is discharged from the separator, and then enters the decomposition and carbonization furnaces at various levels for graded decomposition and carbonization. Th...

Embodiment 3

[0051] The process of the graded decomposition carbonization and harmless treatment of industrial waste salt in this embodiment is carried out according to the following steps:

[0052] (1) Take 1000kg of waste salt material from an environmental protection enterprise, of which: potassium chloride content is 86.4%, water content is 10.3%, organic matter content is 1.2%, and other substances are 2.1%. 200 ℃, the dry tail gas is separated from the gas and solid by the separator, and then sent to the incinerator by the induced draft fan for harmless treatment. The hot gas generated by the incineration is supplemented by the heating furnace of the carbonization system, and the excess hot gas is recycled by the waste heat boiler, cooled, Drain after rinsing.

[0053] (2) The dried industrial waste salt is discharged from the separator, and then enters the decomposition and carbonization furnaces at various levels for graded decomposition and carbonization. The temperature of graded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com