Inner finned tube condenser

A technology of inner fins and condensers, applied in the field of heat exchange equipment, can solve the problems of hindering the heat exchange of cold and hot materials, damage of components, and decrease of heat exchange coefficient, so as to achieve the effects of improving safety, strengthening heat transfer, and speeding up flow rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

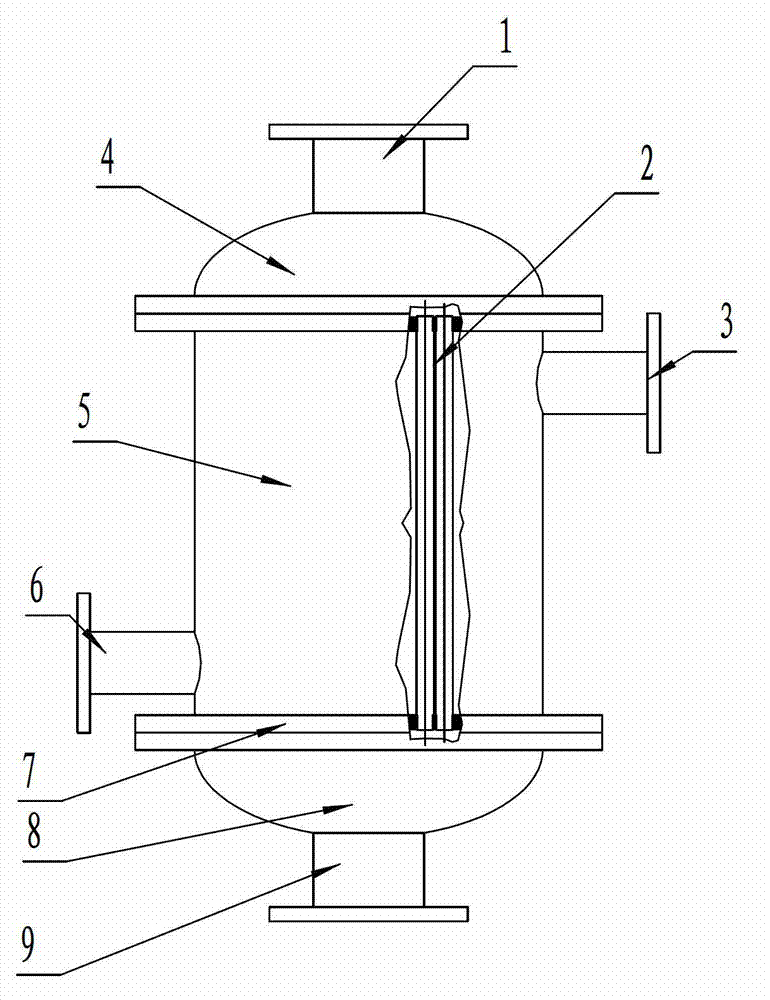

[0015] Embodiment 1, an internal finned tube condenser, including a vertical shell 5, an upper tube box 4 with a tail gas inlet 1, a lower tube box 8 with a condensate outlet 9, a cold water inlet 6, hot water The outlets 3 are respectively located on the lower and upper sides of the shell, and are characterized in that the inner fin type heat exchange tubes 2 are installed between the tube plates at both ends of the shell.

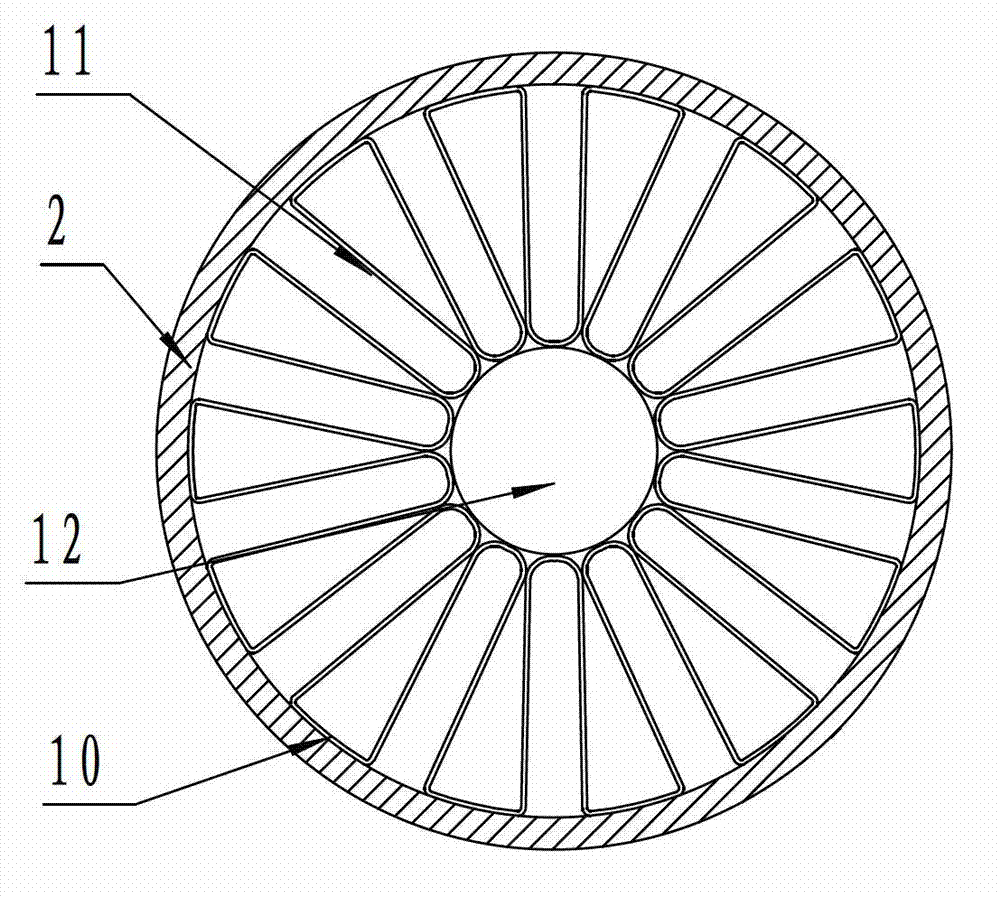

[0016] The structure of the internal fin heat exchange tube is that the center of the heat exchange tube is provided with an inner pin 12, and both ends of the inner pin are provided with sealing plugs. A radial inner fin 11 is installed between the inner pin and the inner wall of the heat exchange tube. Both ends of the inner pin in the middle of the heat exchange tube are provided with sealing plugs.

Embodiment 2

[0017] Embodiment 2, an internal finned tube condenser, comprising a vertical shell 5, an upper tube box 4 with a tail gas inlet 1, a lower tube box 8 with a condensate outlet 9, a cold water inlet 6, hot water The outlets 3 are respectively located on the lower and upper sides of the shell, and are characterized in that the inner fin type heat exchange tubes 2 are installed between the tube plates at both ends of the shell. The structure of the internal fin heat exchange tube is that the center of the heat exchange tube is provided with an internal pin, and both ends of the internal pin are provided with sealing plugs. The U-shaped fins 11 whose arc-shaped top ends are tangent to the inner pin are arranged in a circular array in the heat exchange tube. Two adjacent U-shaped fins are connected to each other at one end close to the inner wall of the heat exchange tube. The infiltrated brazing layer 10 is connected. The U-shaped fin whose inner arc-shaped top end of the heat exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com