Double-layer threaded turbulent flow heat exchanger

A technology of heat exchanger and thread, which is applied in the field of double-layer thread spoiler heat exchanger, can solve the problems of high manufacturing cost, unsatisfactory heat exchange efficiency, low pressure bearing capacity of heat exchanger, etc. Low cost, low cost, and improved heat utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

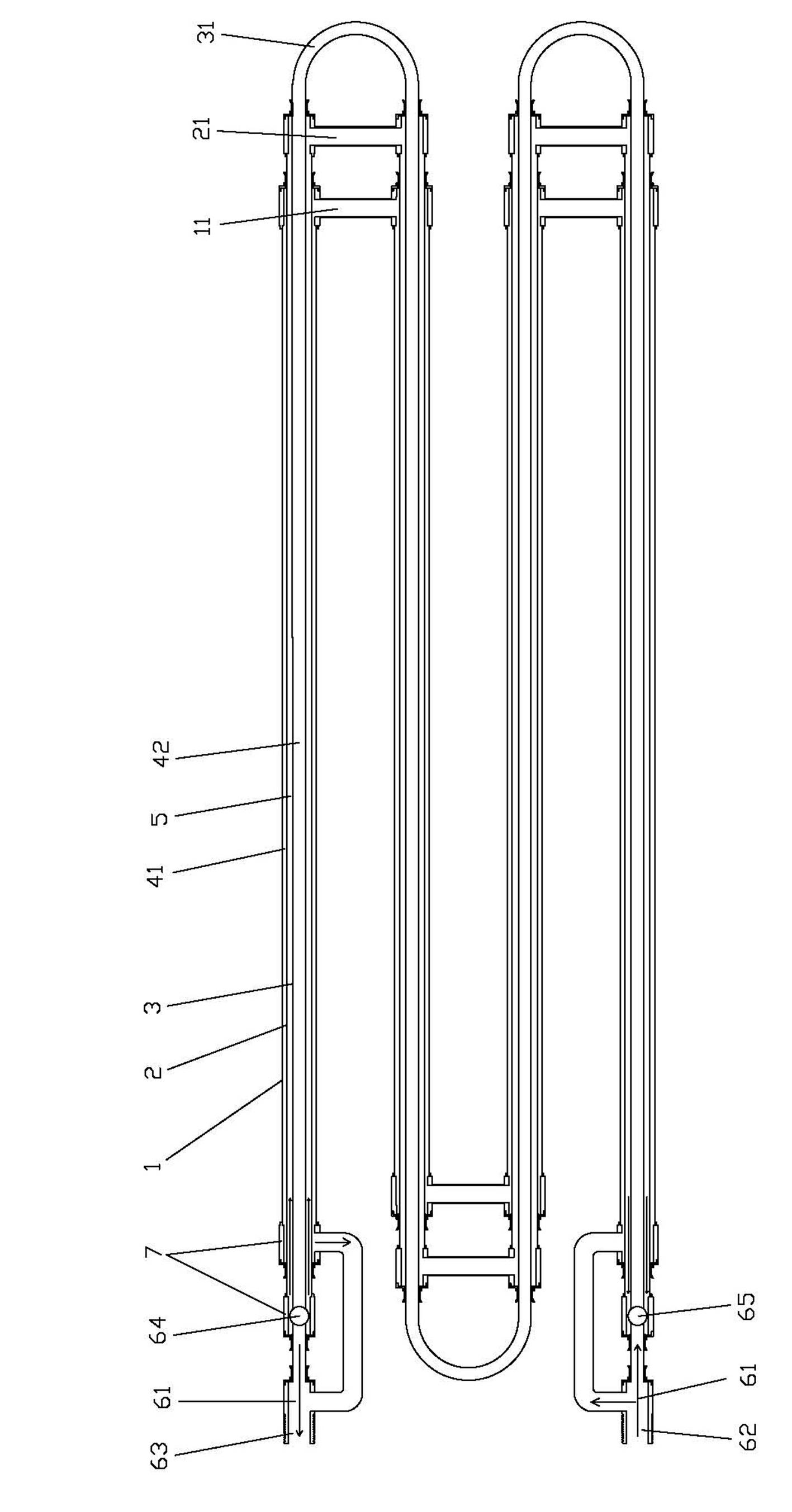

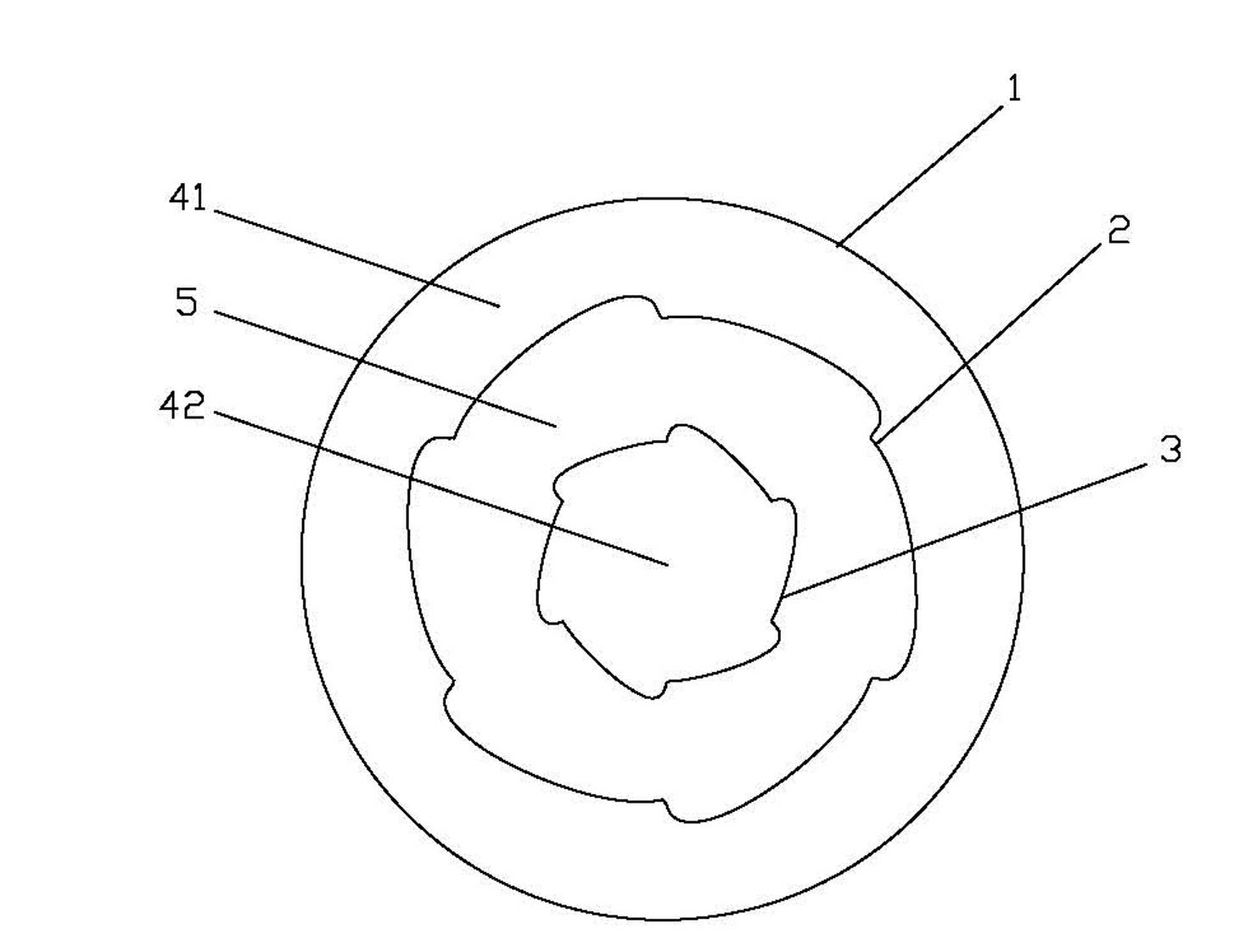

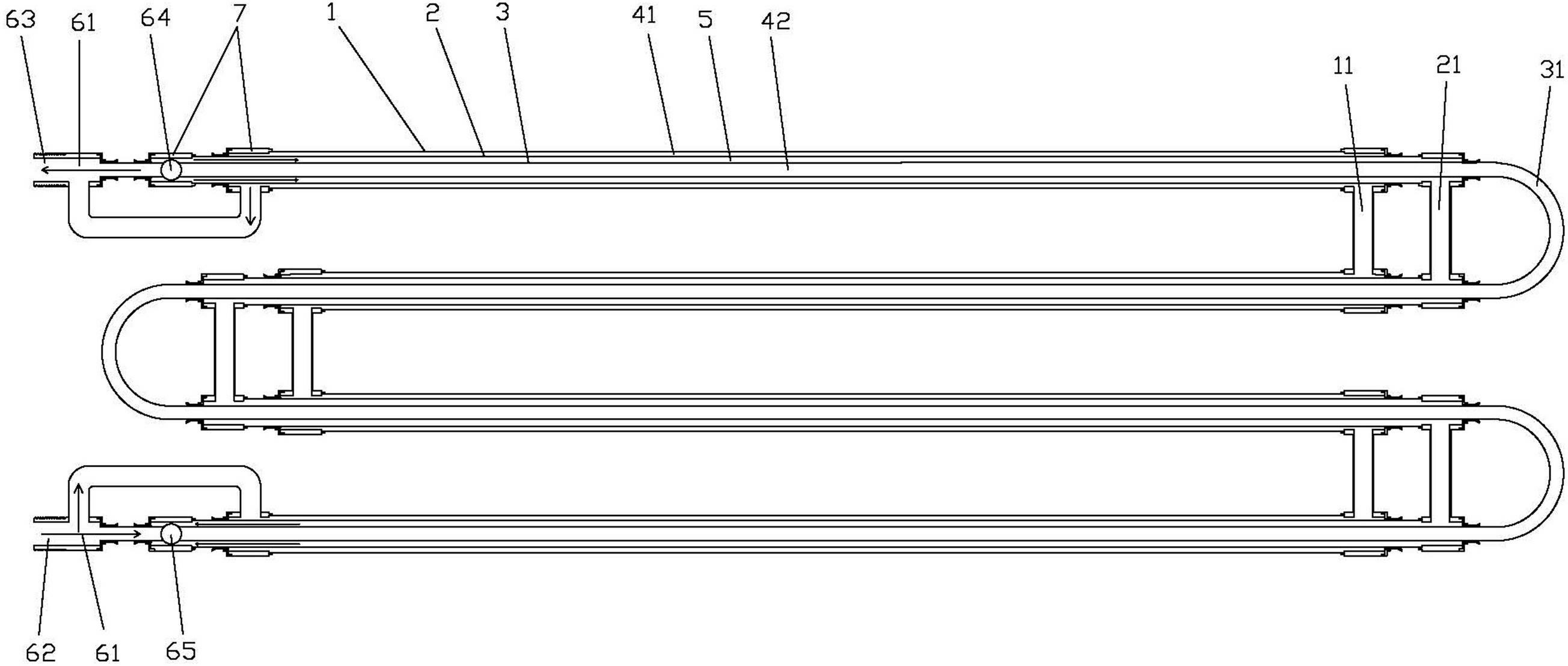

[0021] Such as figure 1 As shown, a double-layer threaded turbulent heat exchanger provided by the present invention includes a coaxial large pipe 1, a middle pipe 2 and a small pipe 3 that are nested together, and the large pipe 1, the middle pipe 2 and the small pipe 3 The stainless steel structure can be connected and fixed through the pipeline connector 7, and the pipeline connector 7 and each pipeline can be welded by argon arc welding or brazing.

[0022] In the present invention, the first cold medium passage 41 is formed between the large pipe 1 and the middle pipe 2, the heat medium passage 5 is formed between the middle pipe 2 and the small pipe 3, and the second cold medium passage 42 is formed in the small pipe 3; thus, Three passages are formed, among which the heat medium passage 5 is used to circulate the heat medium, the first cold medium passage 41 and the second cold medium passage 42 are used to circulate the cold medium, and the heat medium passage 5 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com