Bidirectional non-uniform matching air distributing water-cooled vibration grate of biomass direct-combustion boiler

A vibrating grate and biomass technology, which is applied to the grate of the hollow grate, the combustion method, etc., to achieve the effects of convenient operation, wide adaptability of biomass, and simple structure of the air chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

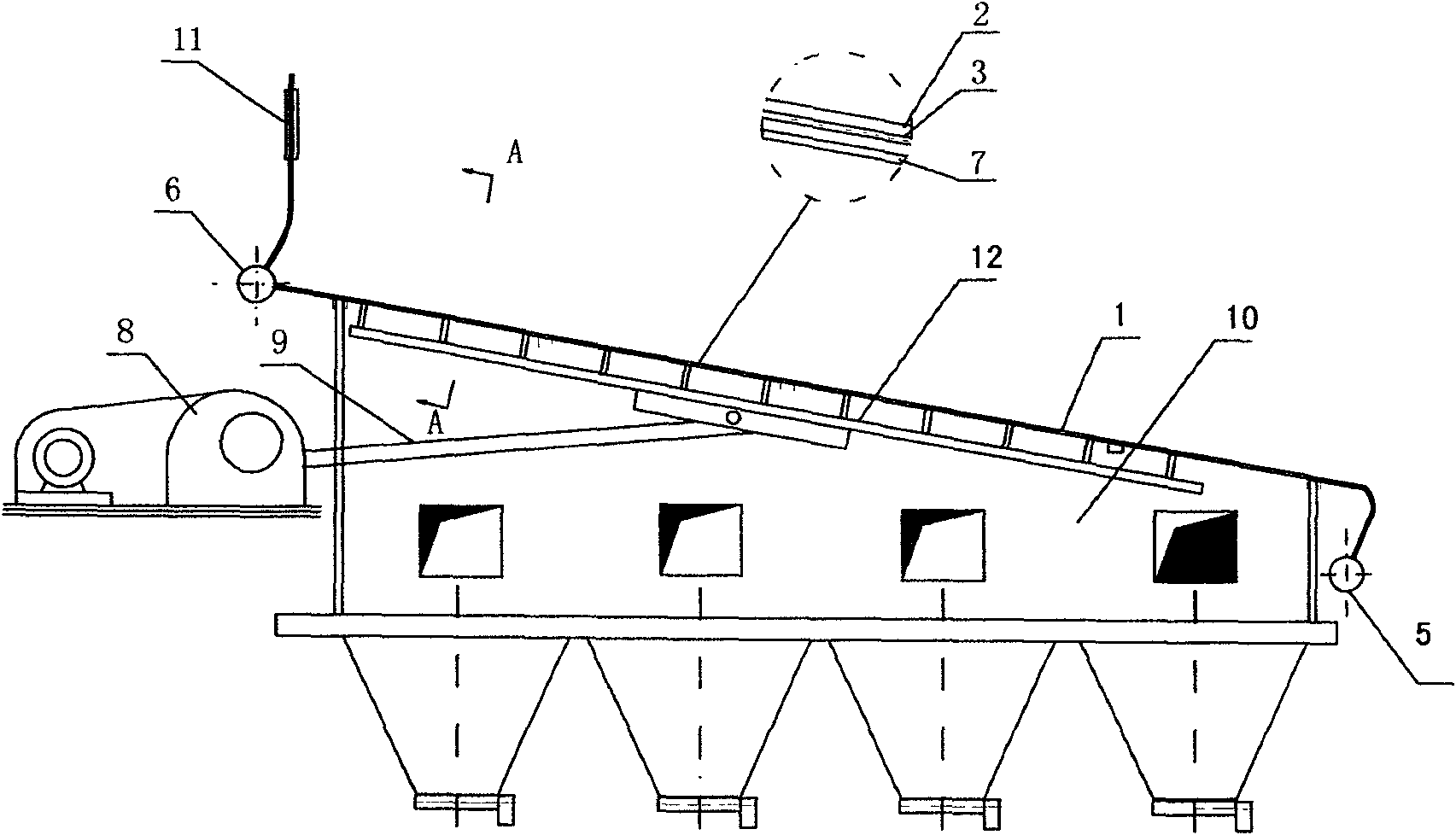

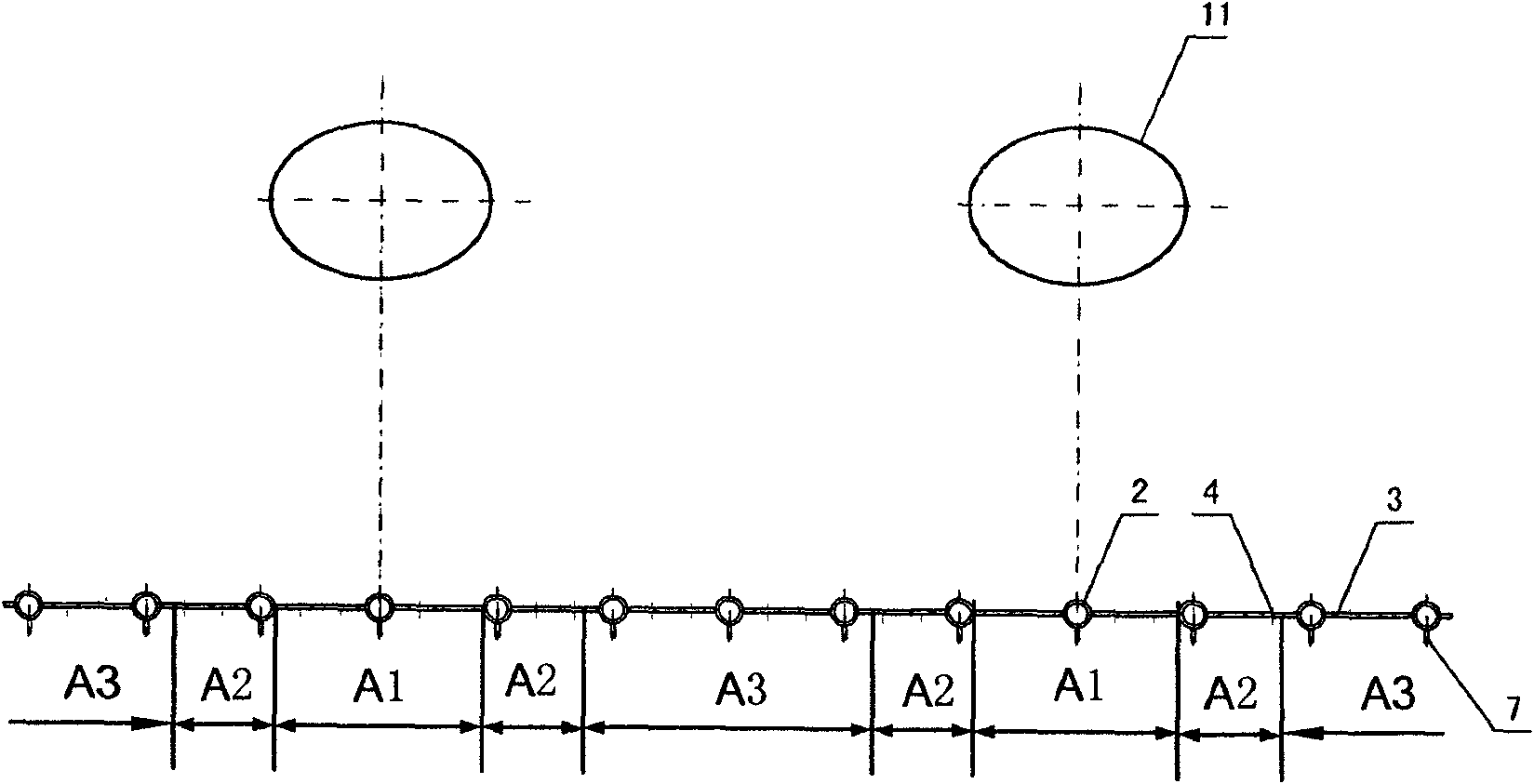

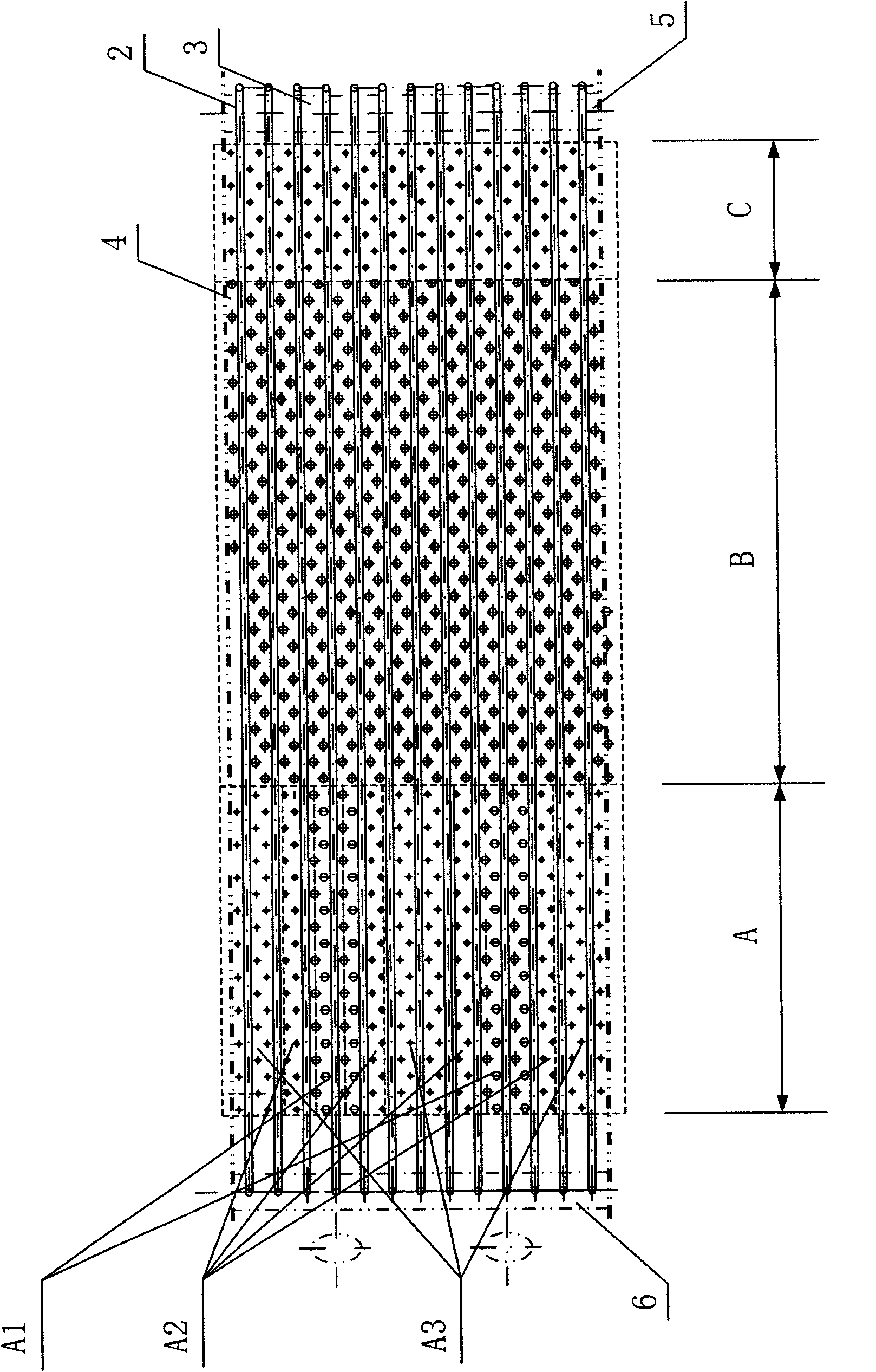

[0016] The water-cooled vibrating fire grate includes a fire grate 1 composed of several inclined water-cooled pipes 2 arranged side by side at a set interval. Below is the discharge port 13; the water cooling tubes 2 are connected by a diaphragm 3, and the diaphragm 3 has an air inlet hole 4; the inlet end of the water cooling tube 2 is connected with the inlet header 5, and the outlet end of the water cooling tube 2 It is connected with the outlet header 6, and the driving device 8 is connected with the support frame 12 at the bottom of the grate 1 through the connecting rod 9, so as to provide vibration for the grate 1.

[0017] (1) In order to prevent the fire grate from being burned out, the present invention adopts a water-cooling method, and the whole fire grate is composed of a water-cooled tube and a diaphragm. The two ends of the water-cooled pipe are respectively connected with the inlet and outlet headers, and the inlet and outlet headers are connected with the boi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com