Method for micro positive pressure oxygen-enriched combustion of pulverized coal

Oxygen-enriched combustion, micro-positive pressure technology, applied in combustion methods, combustion equipment, indirect carbon dioxide emission reduction, etc., can solve problems such as air leakage, ignition and stable combustion difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

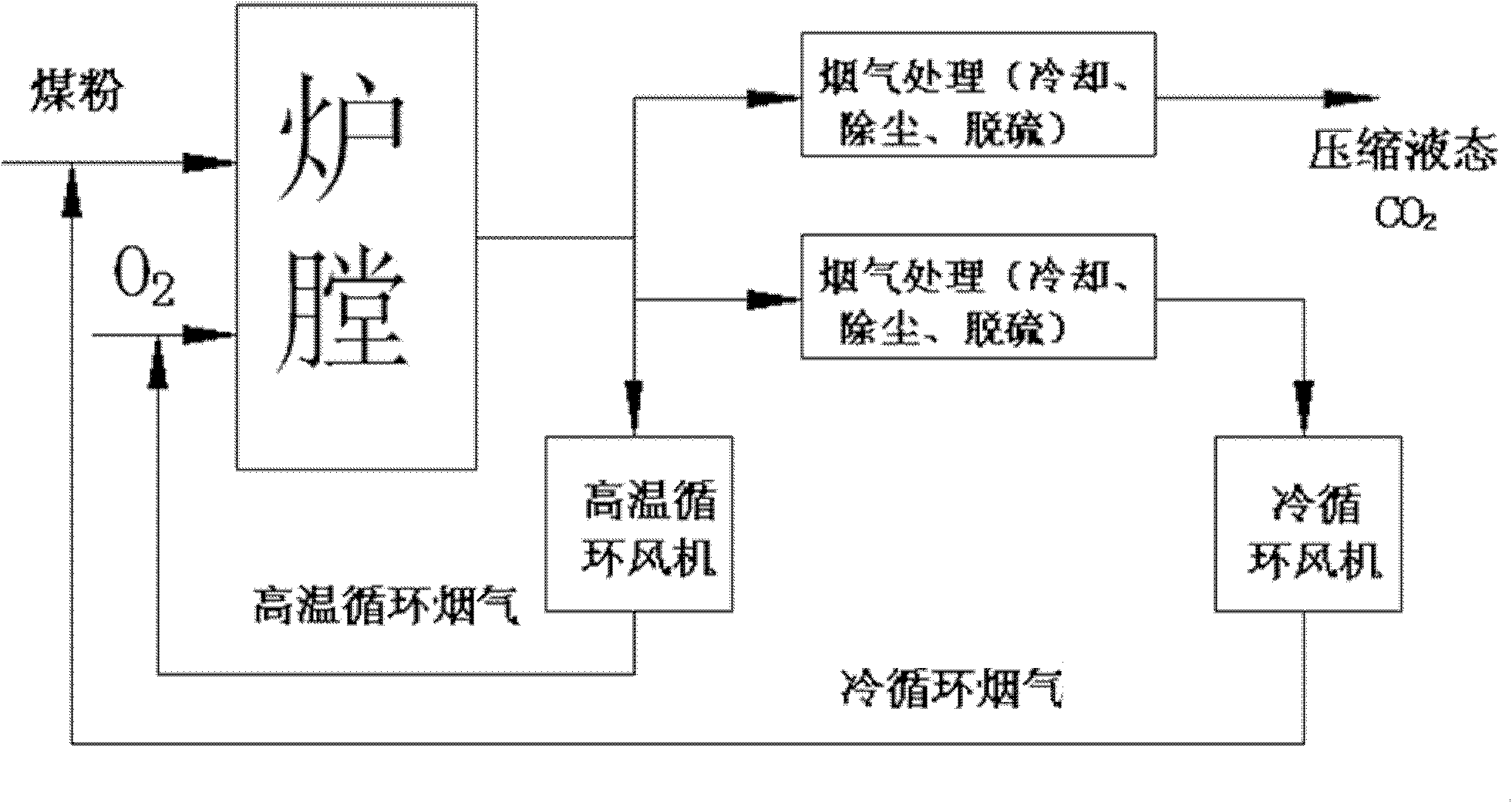

[0021] Ignition and combustion step: use the circulating flue gas to transport pulverized coal to the furnace, and at the same time, separate the air to obtain O 2 into the furnace, ignited and burned;

[0022] Flue gas circulation steps: the high-temperature flue gas produced by the combustion of pulverized coal in the furnace is divided into two parts. The first part of high-temperature flue gas accounts for 30% of the total high-temperature flue gas volume. After cooling, dust removal and desulfurization, it is compressed into liquid CO 2 ;The second part of high-temperature flue gas accounts for 70% of the volume of all high-temperature flue gas, which is used as circulating flue gas;

[0023] The second part of high-temperature flue gas is further divided into two paths: the first path of high-temperature flue gas accounts for 60% of the volume of circulating flue gas. Income O 2 Enter the furnace after mixing, after mixing O 2 The volume accounts for 30% of the volume...

Embodiment 2

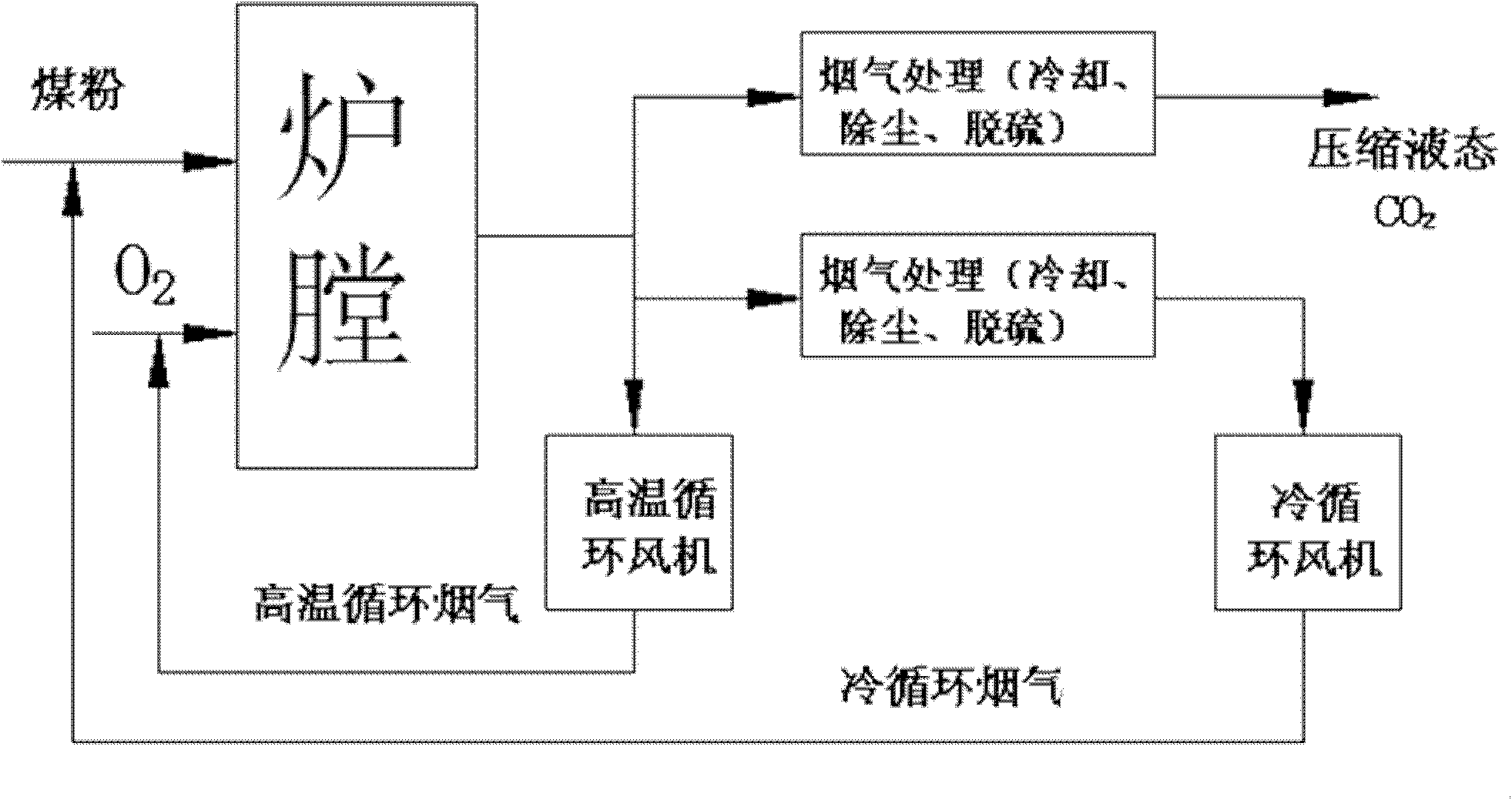

[0026] Ignition and combustion step: use the circulating flue gas to transport pulverized coal to the furnace, and at the same time, separate the air to obtain O 2 into the furnace, ignited and burned;

[0027] Flue gas circulation steps: the high-temperature flue gas produced by the combustion of pulverized coal in the furnace is divided into two parts. The first part of high-temperature flue gas accounts for 30% of the total high-temperature flue gas volume. After cooling, dust removal and desulfurization, it is compressed into liquid CO 2 ;The second part of high-temperature flue gas accounts for 70% of the volume of all high-temperature flue gas, which is used as circulating flue gas;

[0028] The second part of high-temperature flue gas is further divided into two paths: the first path of high-temperature flue gas accounts for 80% of the volume of circulating flue gas. Income O 2 Enter the furnace after mixing, after mixing O 2 The volume accounts for 30% of the mixed ...

Embodiment 3

[0031] Ignition and combustion step: use the circulating flue gas to transport pulverized coal to the furnace, and at the same time, separate the air to obtain O 2 into the furnace, ignited and burned;

[0032] Flue gas circulation steps: the high-temperature flue gas produced by the combustion of pulverized coal in the furnace is divided into two parts. The first part of high-temperature flue gas accounts for 50% of the total high-temperature flue gas volume. After cooling, dust removal and desulfurization, it is compressed into liquid CO 2 ; The second part of high-temperature flue gas accounts for 50% of the volume of all high-temperature flue gas, which is used as circulating flue gas;

[0033] The second part of high-temperature flue gas is further divided into two paths: the first path of high-temperature flue gas accounts for 60% of the volume of circulating flue gas. Income O 2 Enter the furnace after mixing, after mixing O 2 The volume accounts for 28% of the volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com