Gas sample collector

A gas sampling and gas technology, applied in the direction of sampling devices, etc., can solve the problems of inconvenient test personnel, low gas volume, and inability to analyze and judge, and achieve the effect of accurate sampling results and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

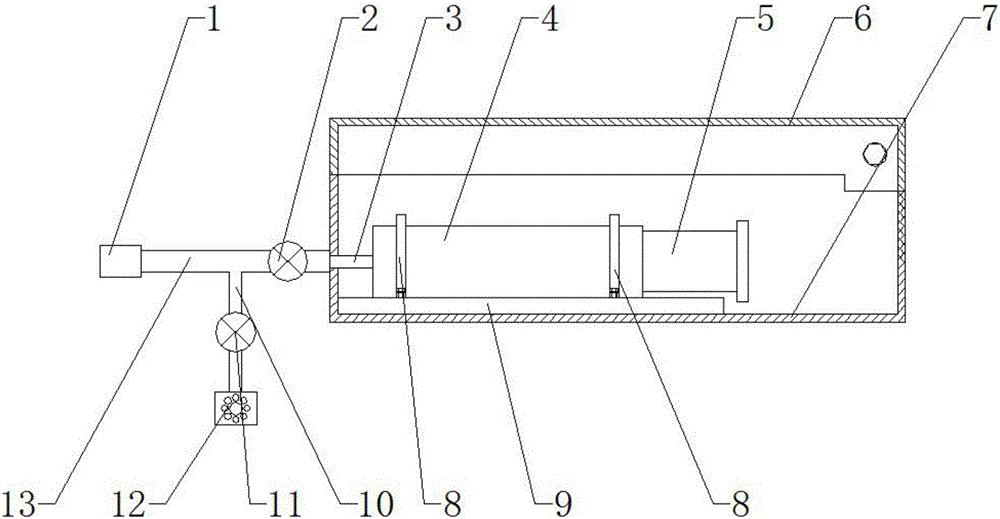

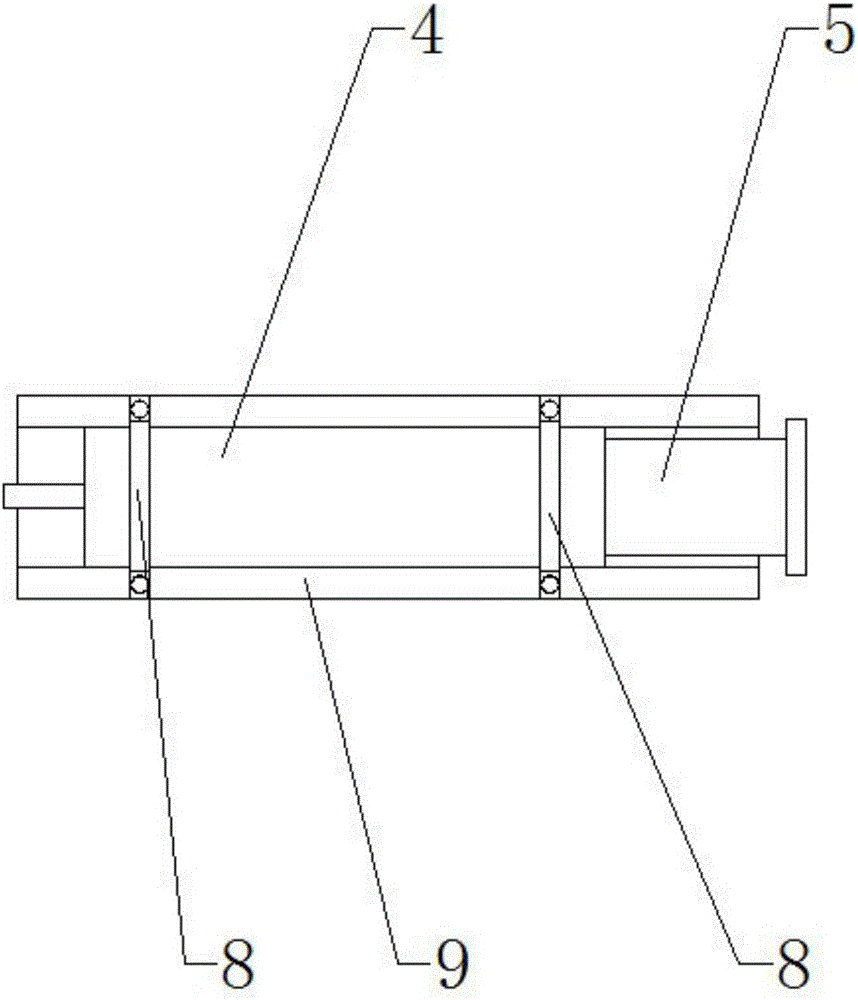

[0027] Embodiment 1: as Figure 1 to Figure 2 As shown, a gas sampler includes a sleeve 4 and a piston rod 5 matched with it. The front end of the sleeve 4 is provided with a first bronchus 3, and the first bronchus 3 communicates with an air guide tube 13, which is far away from the sleeve. One end of 4 is provided with a rubber head 1, and the air duct 13 is connected with a second bronchus 10, and the end of the second bronchus 10 away from the air duct 13 is provided with a combustion head 12, and the first bronchus 3 is provided with a first valve 2, and the second bronchus 10 is provided with a second valve 11.

[0028] It also includes a housing, and a cavity matching the sleeve 4 and the piston rod 5 is arranged in the housing.

[0029] The sleeve 4 and the piston rod 5 are located in the housing, and the front end of the first bronchus 3 passes through the housing and communicates with the air duct 13 .

[0030] The casing includes an upper casing 6 and a lower casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com