Ignition control method

An ignition control and igniter technology, which is applied in the direction of combustion ignition, combustion method, and ignition by guiding the flame tongue, etc., can solve problems such as safety hazards, difficult maintenance of high-altitude ignition head, unstable ignition performance, etc., and achieve high ignition success rate and high combustion efficiency. Powerful, easy-to-maintain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

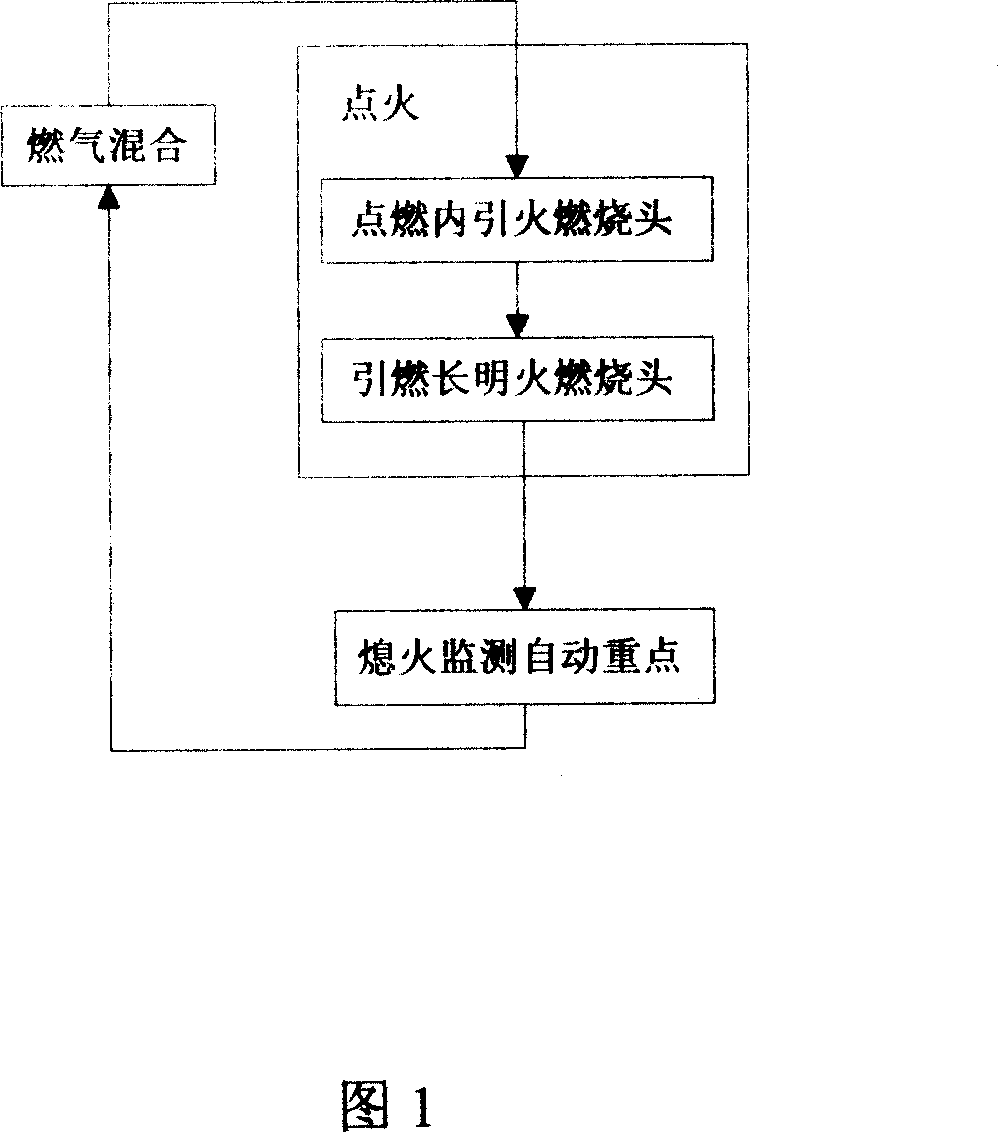

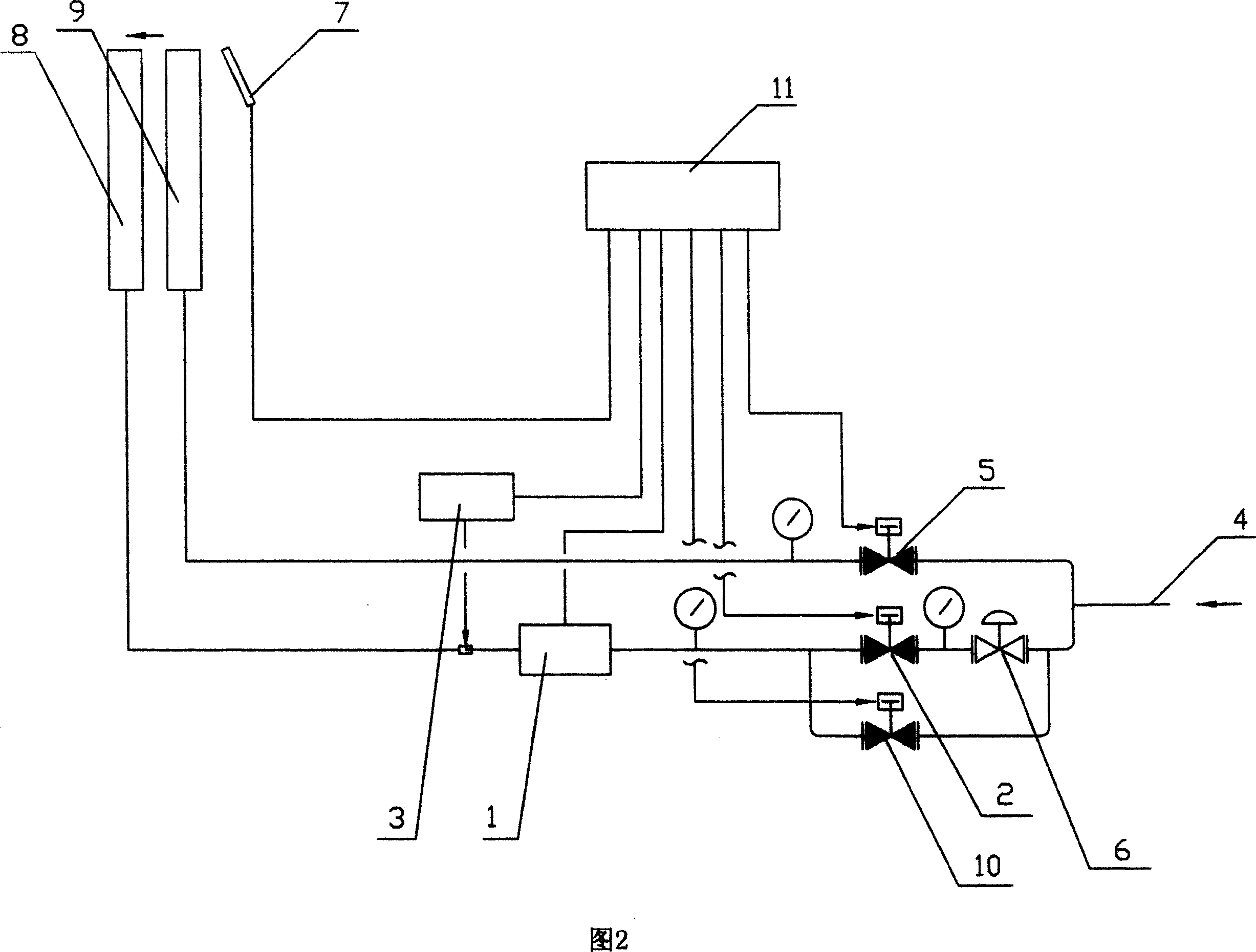

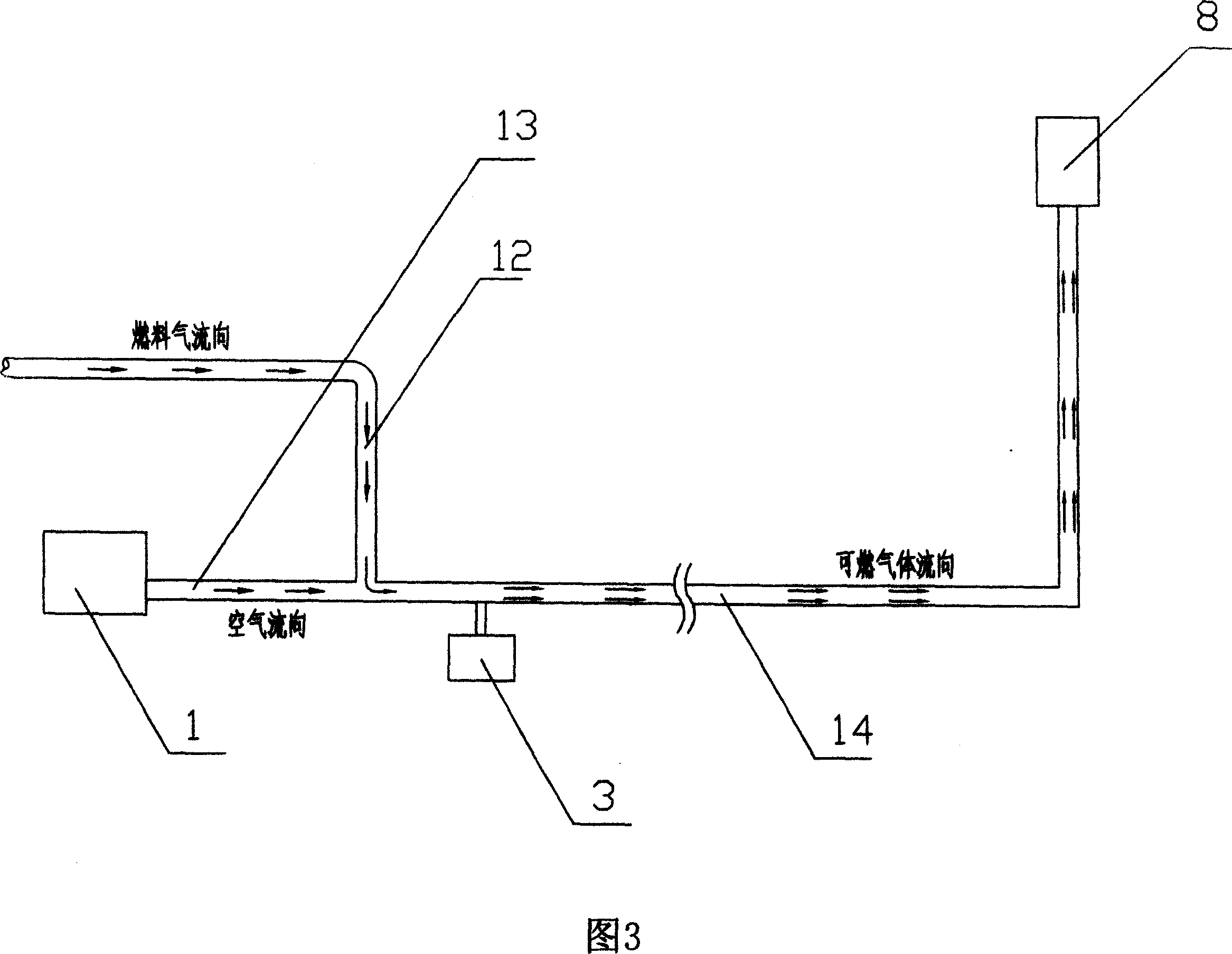

[0020] As shown in FIG. 1 , the ignition control method disclosed in the present invention is applied in the waste gas high-altitude flare ignition system in the petrochemical industry. The ignition control method mainly includes the automatic key steps of gas mixing, ignition, and flameout monitoring. The ignition includes igniting the internal pilot combustion head and igniting the eternal flame combustion head. As shown in Figure 2, the gas enters through the gas inlet 4 and passes into the inner ignition pipe and the permanent flame pipe respectively. The inner ignition control valve 2 and the pressure regulating valve 6 connected in series are arranged on the inner ignition pipe. Pilot control valve 2 and pressure regulating valve 6 are in parallel bypass control valve. First press the opening button of the automatic control system 11, the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com