Process for preparing ceramic cartridge for super long type high voltage fuse

A technology of high-voltage fuses and ceramic shells, which is applied to electrical components, circuits, emergency protection devices, etc., and can solve problems such as product deformation and bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

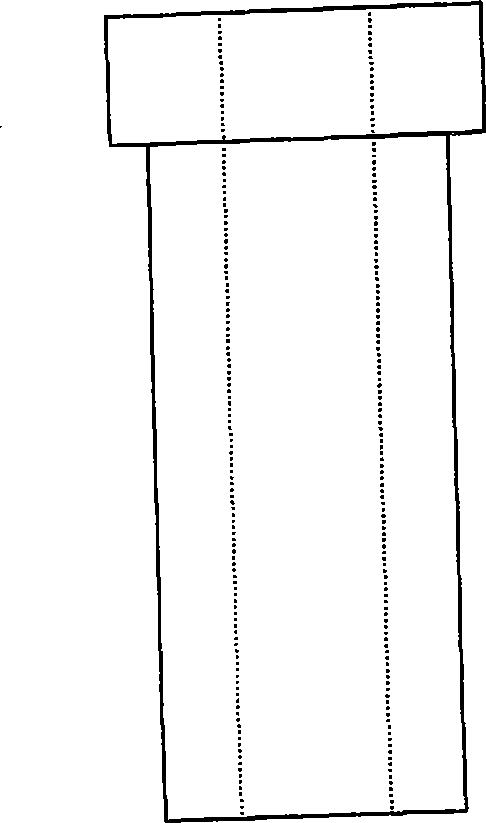

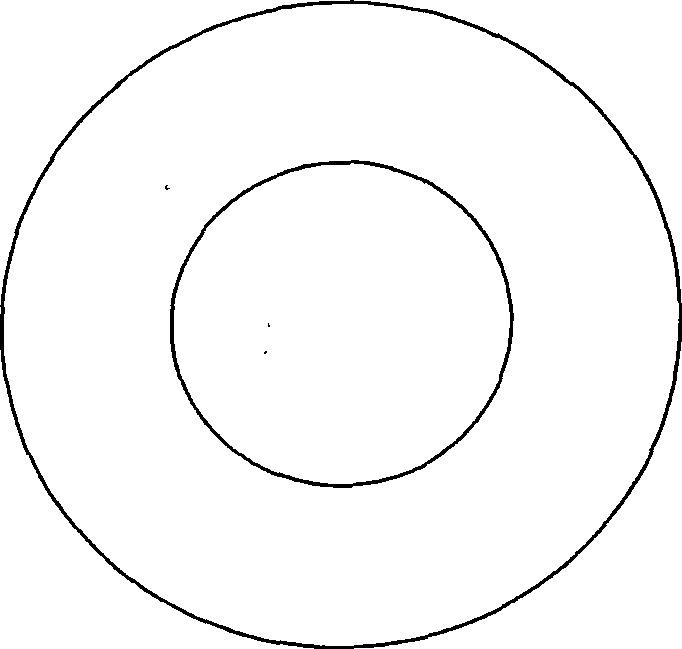

[0017] The ultra-long high-voltage fuse ceramic shell is made of special porcelain formula. After batching, spraying granulation, and isostatic pressing, it is turned into a blank to be burnt with a hanging burner, and a special firing shed is used. And hang-fired kiln furniture, which is fired at high temperature in a high-temperature kiln by hanging and set. Products and hoisting pad rings such as Picture 1-1 , 1-2 shown.

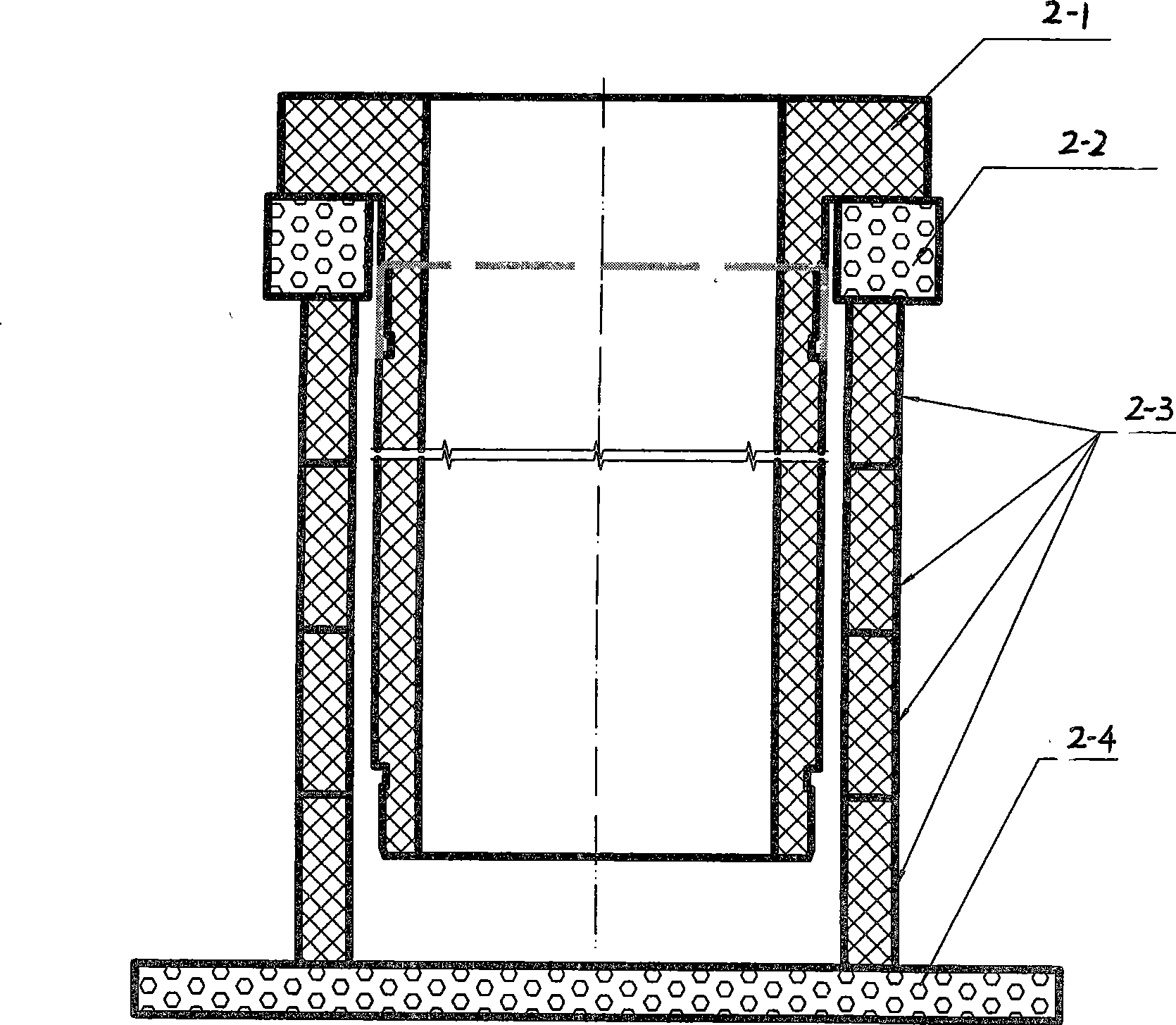

[0018] The processing method of the ultra-long fuse ceramic shell is as follows: figure 2 As shown, the bottom layer is flat and high-temperature refractory shed board with a refractoriness of 1800°C; on the shed board is a special porcelain cylinder made of special ceramics, which needs to be fired at high temperature in advance to make porcelain. After grinding and processing, the thickness of the porcelain cylinder is uniform and the size is consistent. The thickness is adjusted according to the product weight (general thickness 10-15mm). After st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com