Burning head device of straw gasifier

A gasifier and combustion head technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of heat loss, insufficient combustion, environmental pollution, etc. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

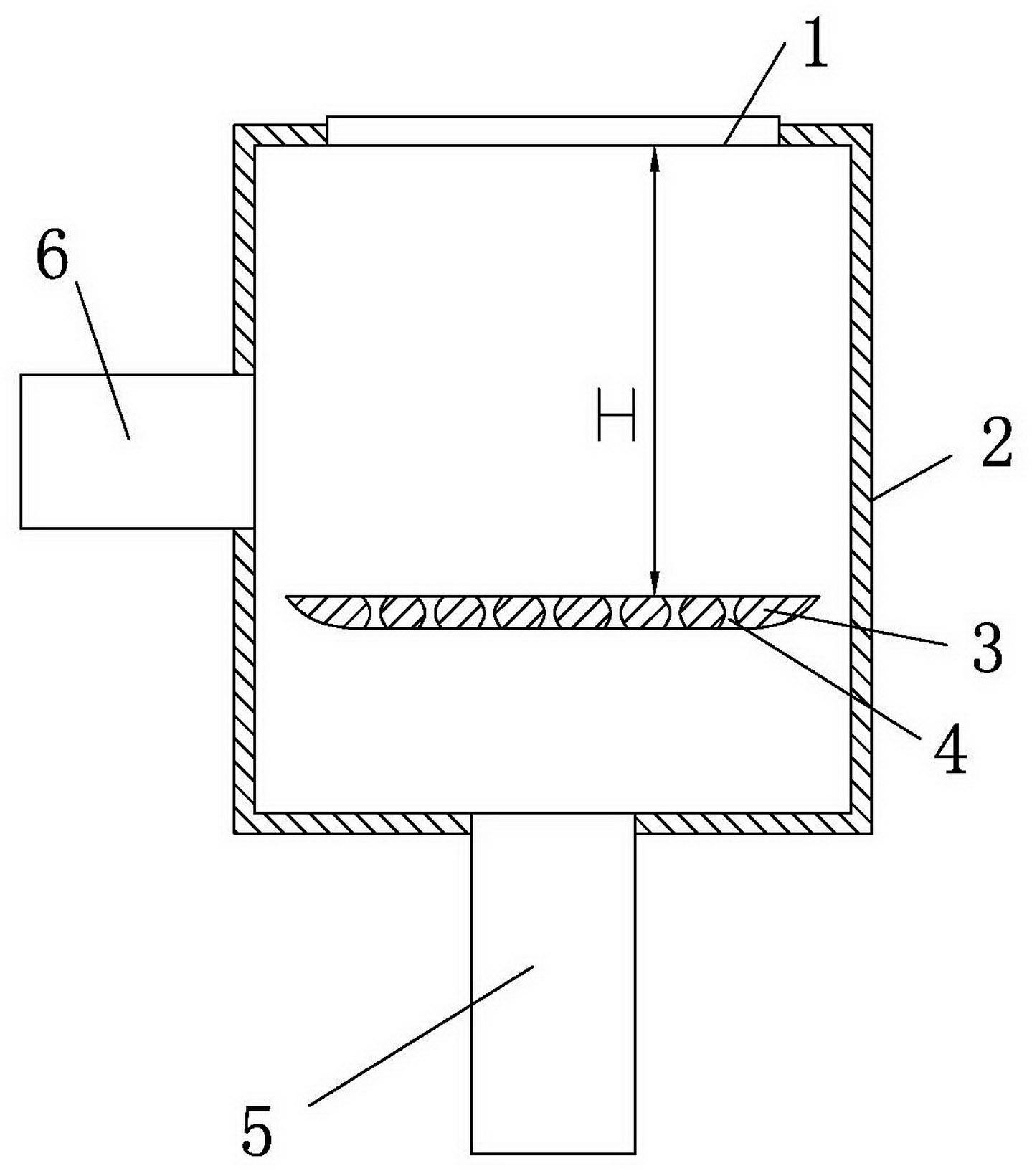

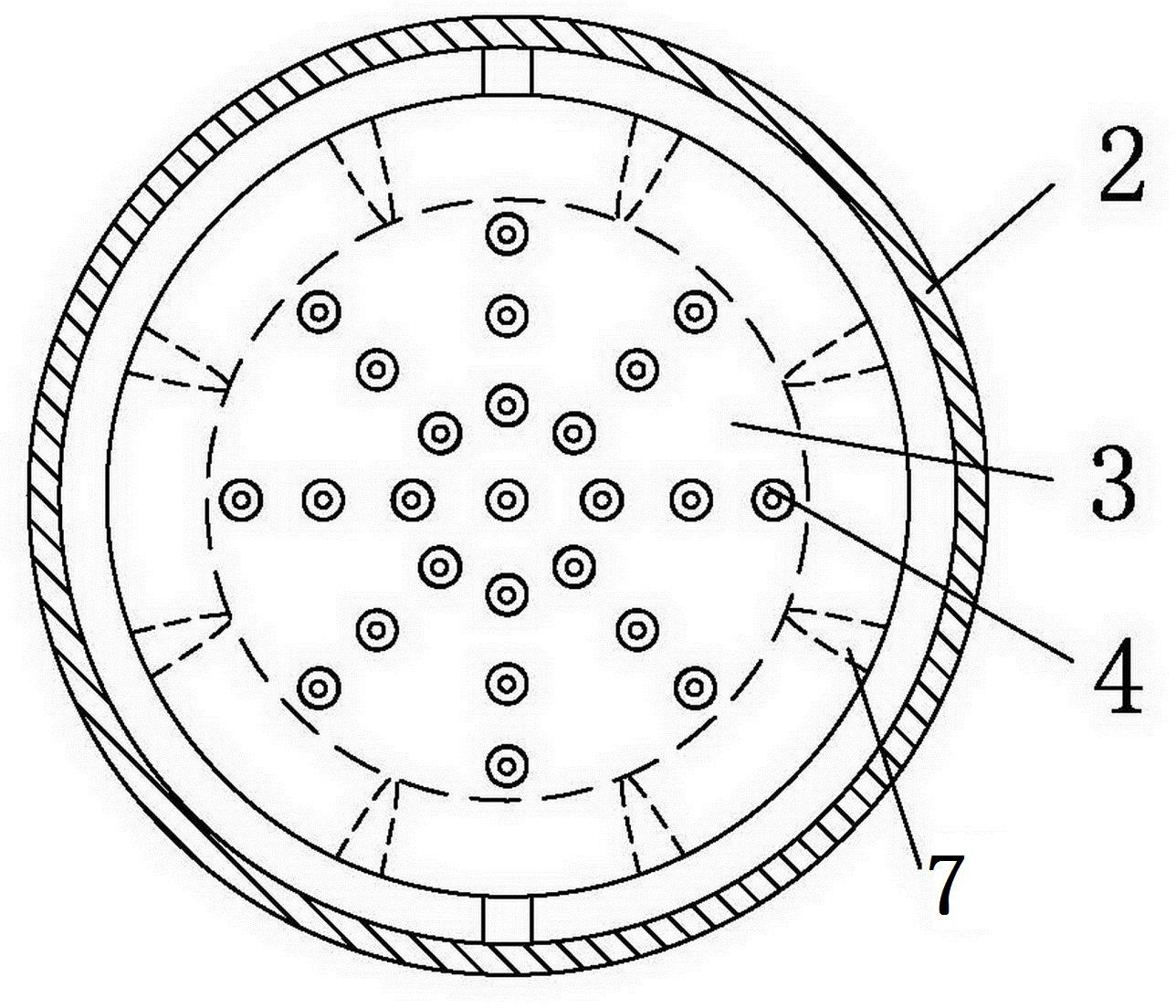

[0010] A combustion head device of a straw gasification furnace, such as figure 1 , figure 2 As shown, the device includes a cylindrical combustion tube 2 with a fire outlet 1 on the top surface. There is an air inlet pipe 6 connected with the blower, and a fire baffle 3 is horizontally arranged in the combustion cylinder below the air inlet pipe mouth, and a combustion chamber is formed in the combustion cylinder between the fire baffle 3 and the mouth of the air intake pipe 5. There is an annular fire gap between the outer peripheral edge of the fire baffle 3 and the inner peripheral wall of the combustion tube 2. The height of the top surface of the fire baffle 3 from the fire outlet is 5-10cm, and the surface of the fire baffle 3 Combustion holes 4 are arranged symmetrically and uniformly on the top. The hole wall of the combustion hole 4 is a rotating hyperboloid, and the central throat aperture of the combustion hole 4 is 5mm. On the outer periphery of the bottom surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com