Open-type methane burning torch

A biogas combustion and open technology, applied in the combustion method, combustion type, incinerator and other directions, can solve the problems such as the adverse impact of biogas emissions on the surrounding environment, biogas combustion de-firing, black smoke and other problems, to avoid secondary pollutants, Strong safety and material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

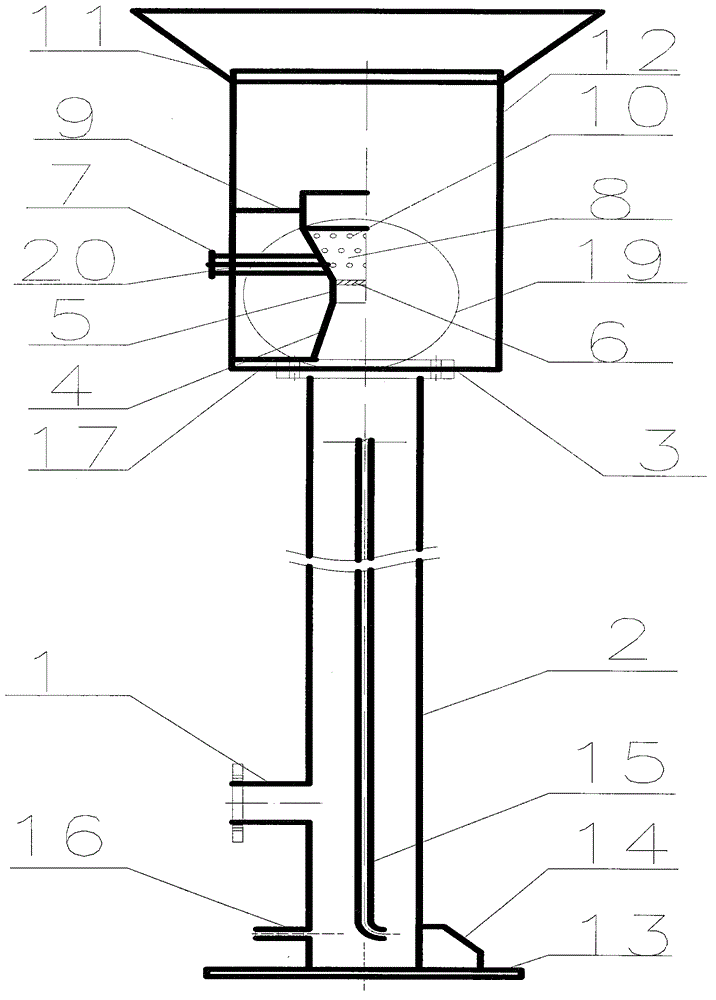

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings. Such as figure 1 , figure 2 shown

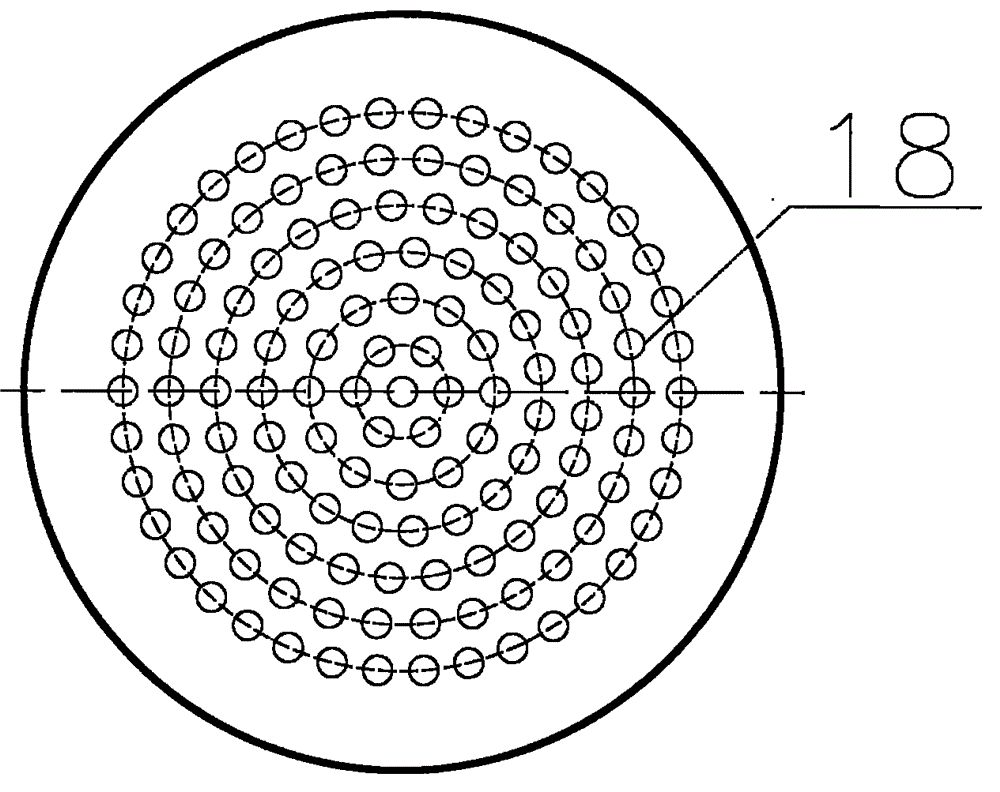

[0012] An open biogas combustion torch of the present invention comprises an air inlet 1, an air inlet main pipe 2, a torch combustion head assembly 19, a windshield 12, and an ignition inlet pipe 15, and a drain pipe 16, The base 13 and the reinforcing rib 14, the air inlet 1 is located above the drain pipe 16, and communicates with the air intake main pipe 2; the torch combustion head assembly 19 includes a gradient tube 4, a throat pipe 5, a flame-retardant cover 6, and a torch combustion head 8; There are combustion-supporting air holes 10 on the combustion head 8; the diameter of the combustion-supporting air holes 10 on the combustion head 8 is 10 mm from bottom to top, and the distance between the upper and lower rows is 20 mm. A circular hole 18 with a diameter of 5 mm. The ignition inlet pipe 15 includes an igni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com