Burner for gas water heater

A technology for gas water heaters and burners, which is applied in the direction of gas fuel burners, burners, and combustion methods. It can solve the problems of unsatisfactory increase in combustion degree, unimproved air supply and mixing uniformity, and reduce emissions. Quantity, ensuring adequacy and thoroughness, and high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

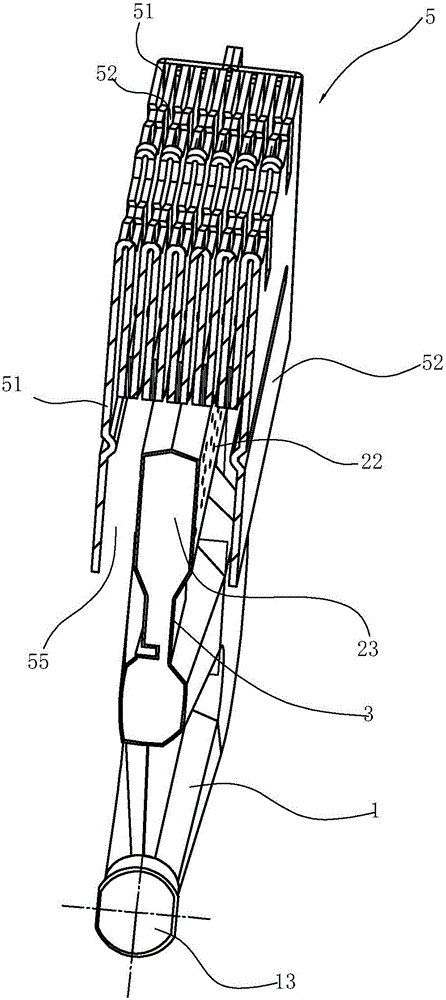

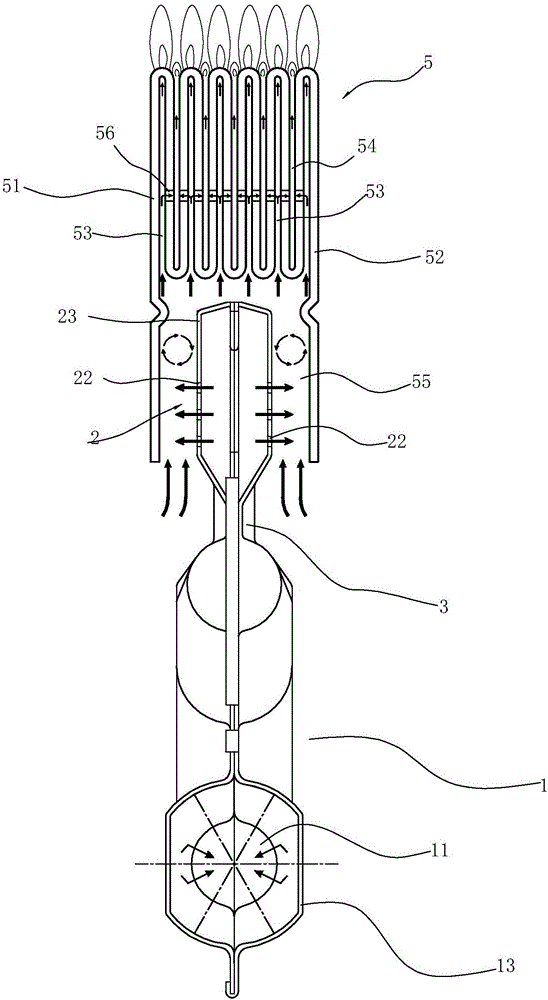

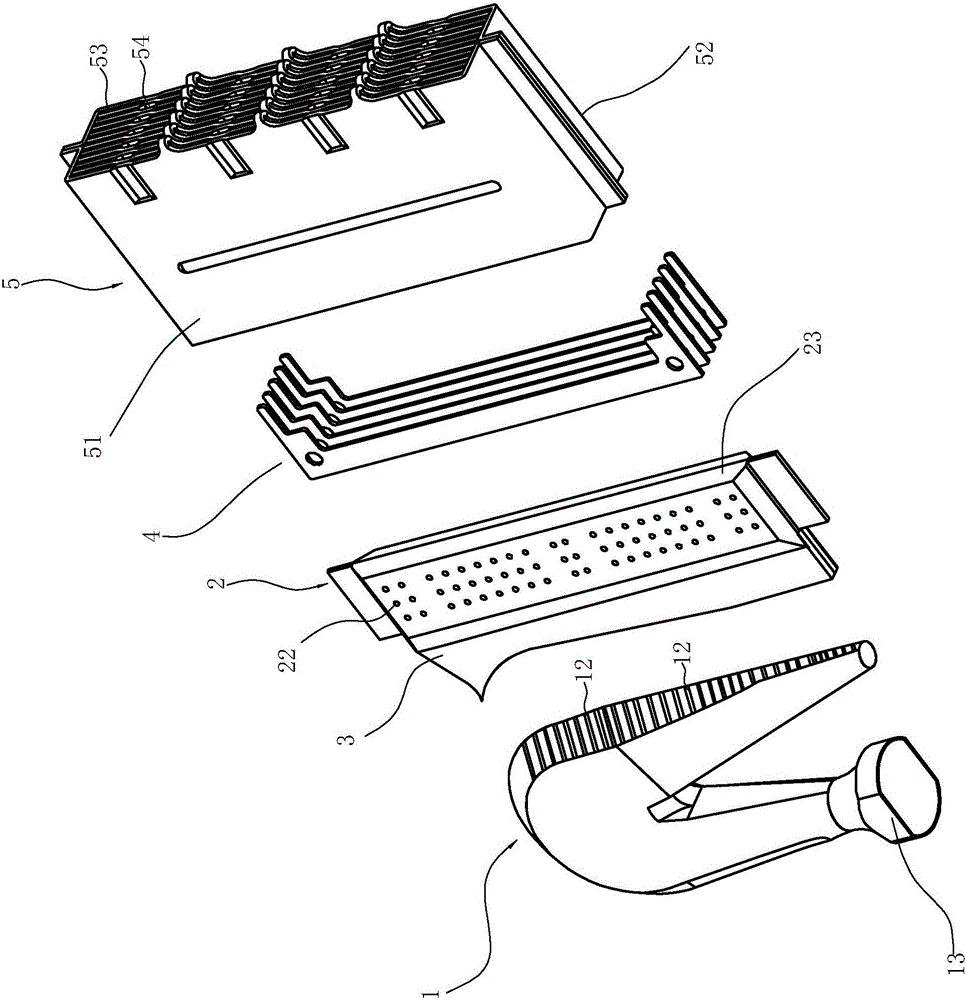

[0025] Such as Figure 1 to Figure 7 As shown, the burner for gas water heater includes:

[0026] Injection pipe 1 is used to initially mix the air and gas entering it, and any structure in the prior art can be selected according to needs. The ejector tube in this embodiment is a hollow tubular structure in a lying "U" structure, and its air inlet 11 is located on the port of the pipe below the ejector tube, and the port is also connected with a horn for easy air intake Port 13; the port of the upper pipeline of the ejector tube is closed, and the gas outlet 12 of the ejector tube is arranged on the side wall of the upper pipeline.

[0027] The air box 2 includes a box body 23 , and the box body 23 is provided with an air inlet and an air outlet 22 . There are multiple air outlets 22 of the air box 2, which are evenly distributed on the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com