Metal-fiber front mixing burner based on central reverse burning head

A metal fiber and combustion head technology, applied to gas fuel burners, burners, combustion methods, etc., to achieve uniform temperature distribution, stable combustion, and reduced overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below in conjunction with examples, which are only used to explain the present invention, and are not intended to limit the scope of the present invention.

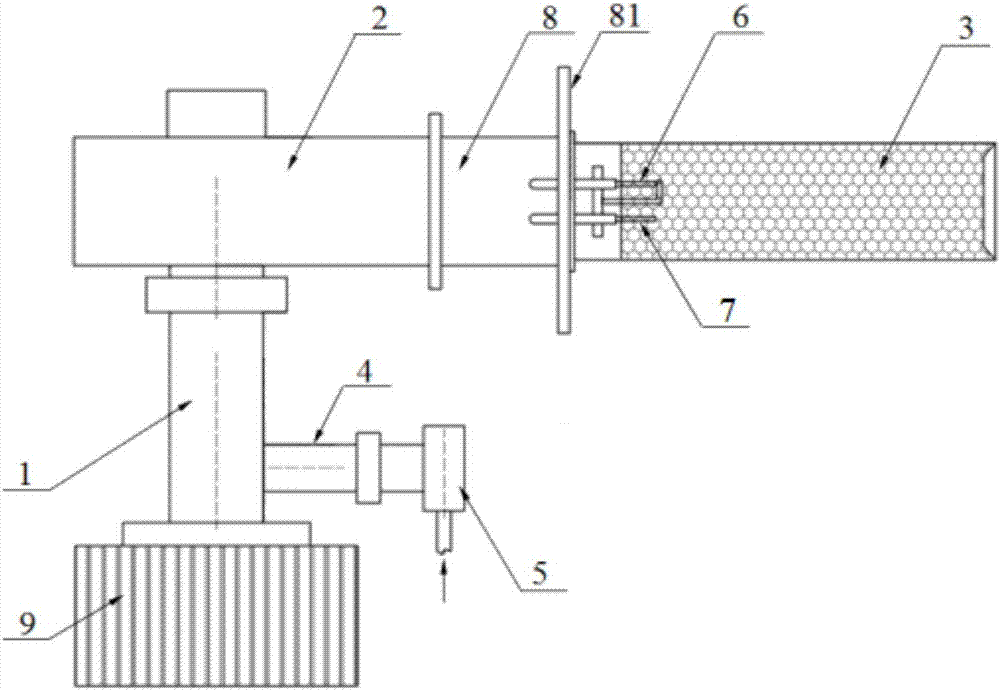

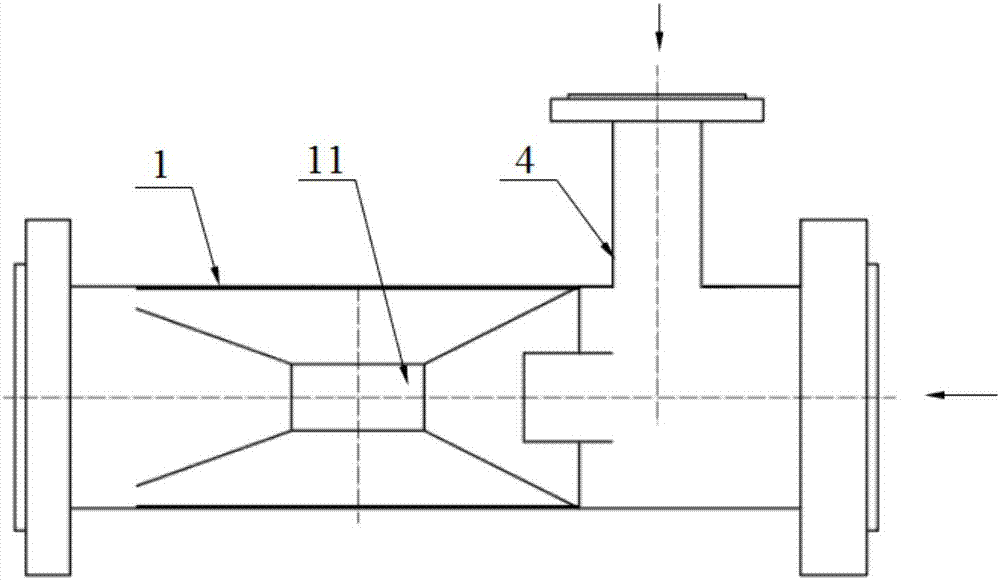

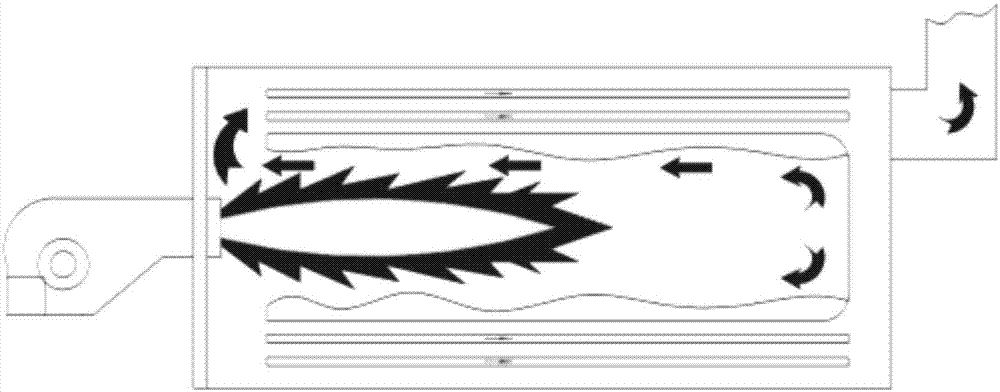

[0031] A metal fiber premix burner based on a center back combustion head, such as figure 1 As shown, it includes a premixing chamber 1, a fan 2 and a central combustion head 3. The premixing chamber 1 has a Venturi structure and is arranged at the air inlet of the fan 2, that is, the air outlet of the premixing chamber 1 and the fan 2, the air outlet of the fan 2 is connected to the central combustion head 3, and the gas and air pass through the premixing chamber 1 and the fan 2 in sequence, and then enter the premixing chamber 1 and the inner cavity of the fan 2 after being mixed twice. The central combustion head 3 burns on the metal fiber surface.

[0032] A branch pipe 4 is opened on the side wall between the inlet of the premixing chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com