Flame spraying gun mainly used for laying water-proof coiled material

The technology of flame spray gun and waterproof coil material is applied in the field of flame spray gun, which can solve the problems of high construction cost, high labor intensity and high price, and achieve the effects of improving work efficiency, reducing labor intensity and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

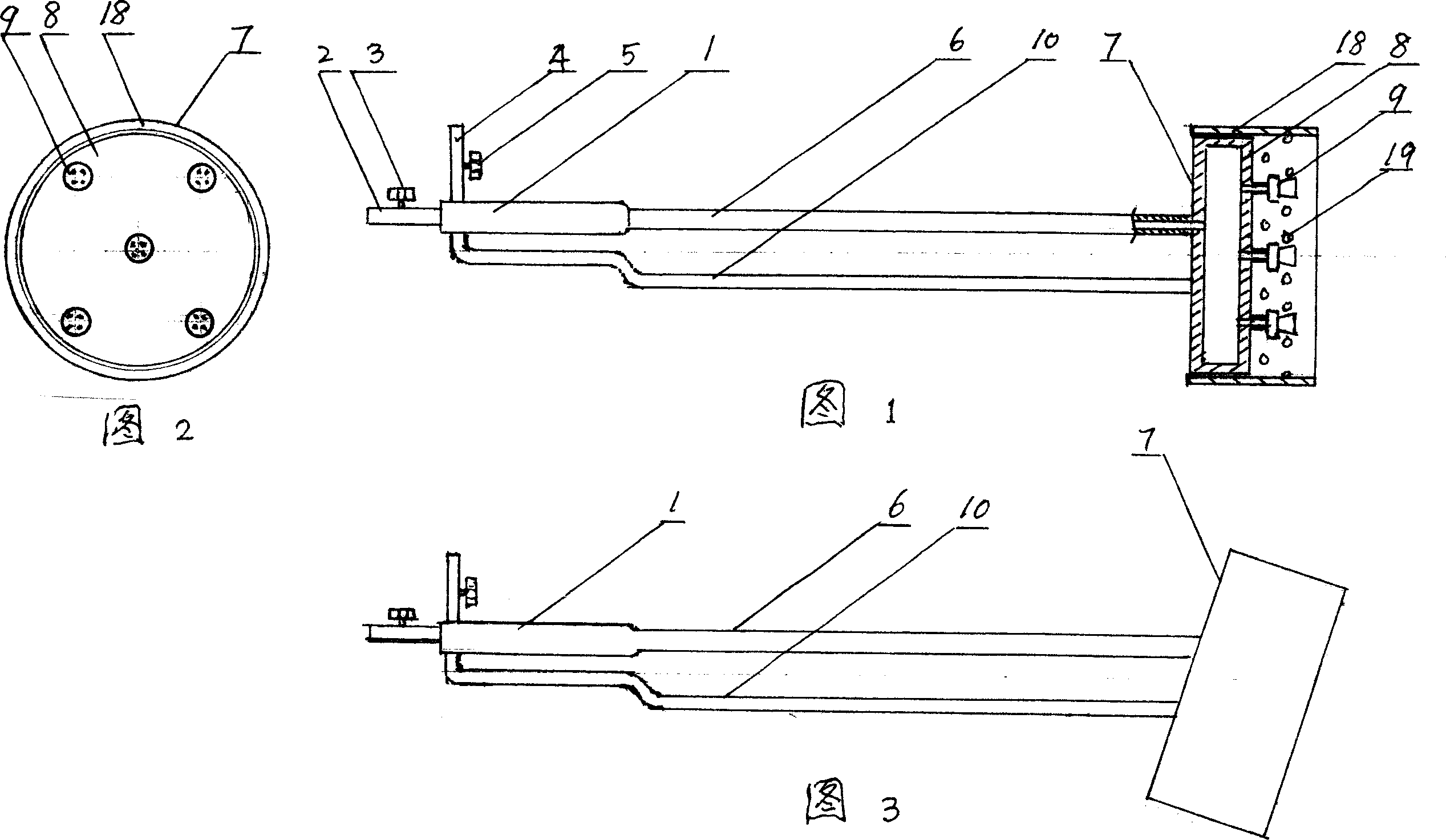

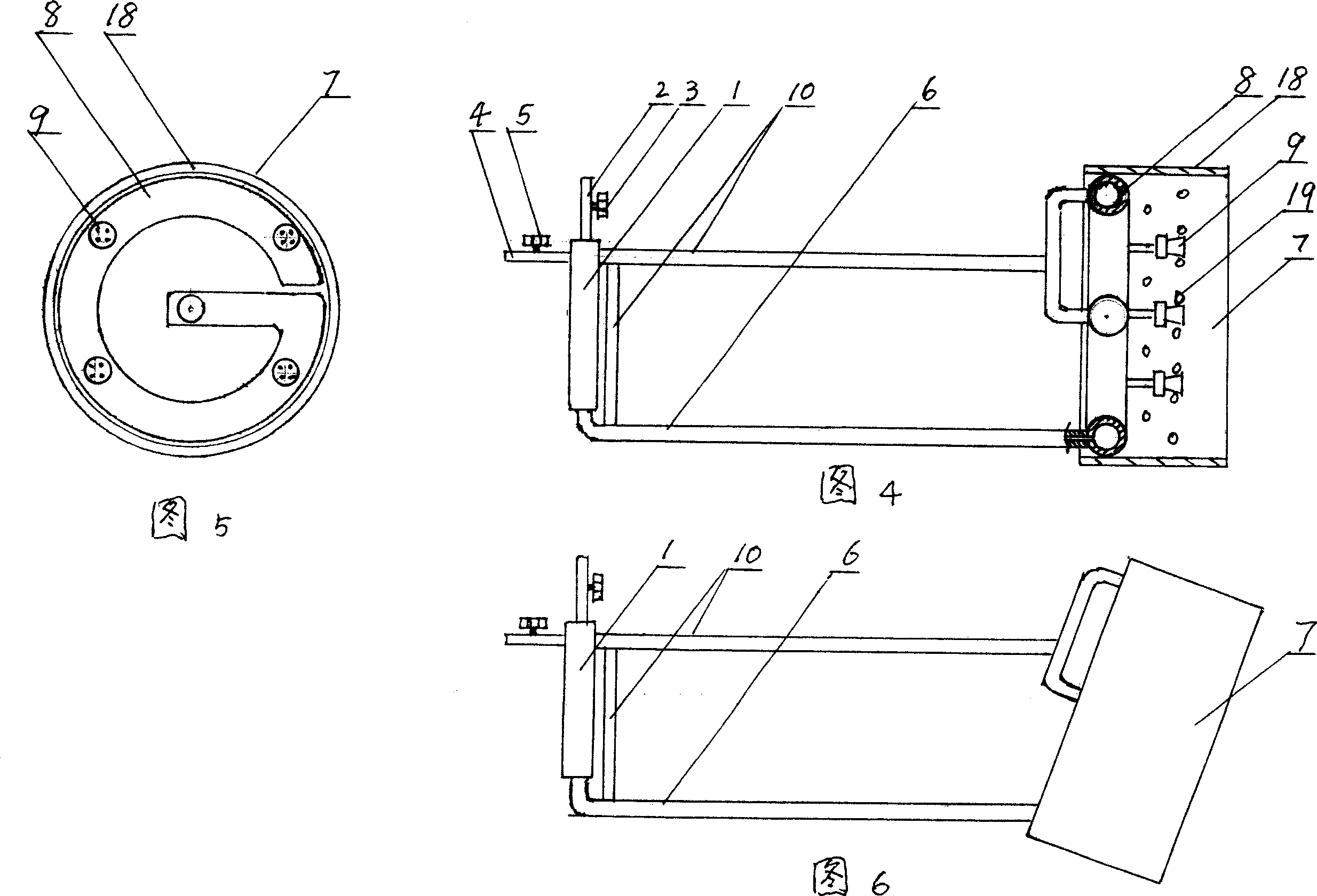

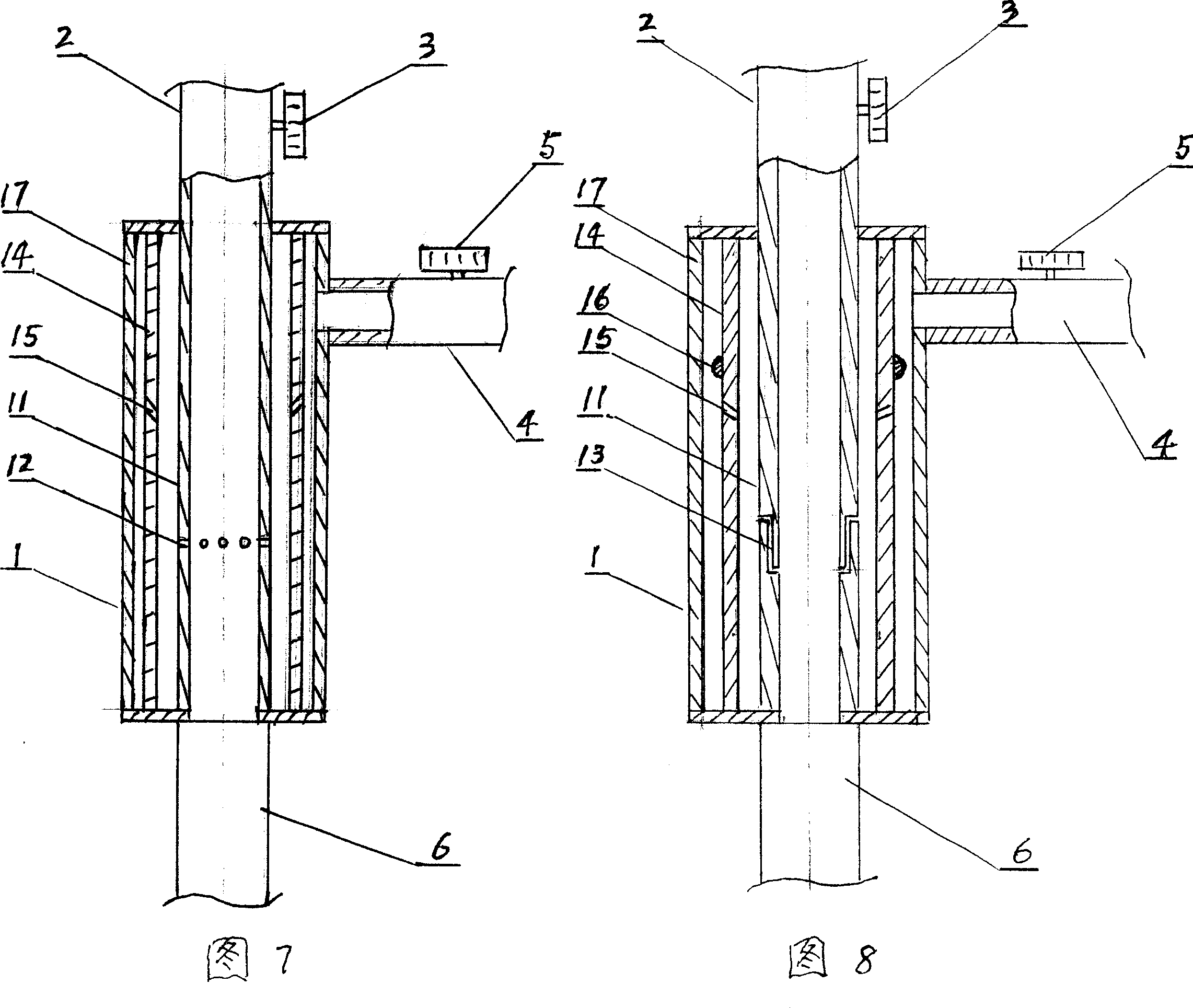

[0016] As shown in the front view of the flat handle vertical combustion head of the present invention in accompanying drawing 1 and the right view of the flat handle vertical combustion head of the present invention in accompanying drawing 2, this flame spray gun is composed of a mixed gas distribution valve 1, a mixed gas delivery pipe 6, and a combustion head 7 1. The supporting fixed rod is composed of 10 parts. The input port 2 of the mixing gas distribution valve 1 is connected to the liquefied gas cylinder through a hose, and the input port 4 is connected to the air compressor through a hose. The input ports 2 and 4 are respectively provided with adjustment knobs 3 and 5, the output port of the mixed gas distribution valve 1 is connected to the interlayer gas tray 8 of the combustion head 7 through the mixed gas delivery pipe 6, and the interlayer gas tray 8 is equipped with 5 flame nozzles 9, and the flame nozzle adopts the existing liquefied gas fierce fire stove nozzl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com