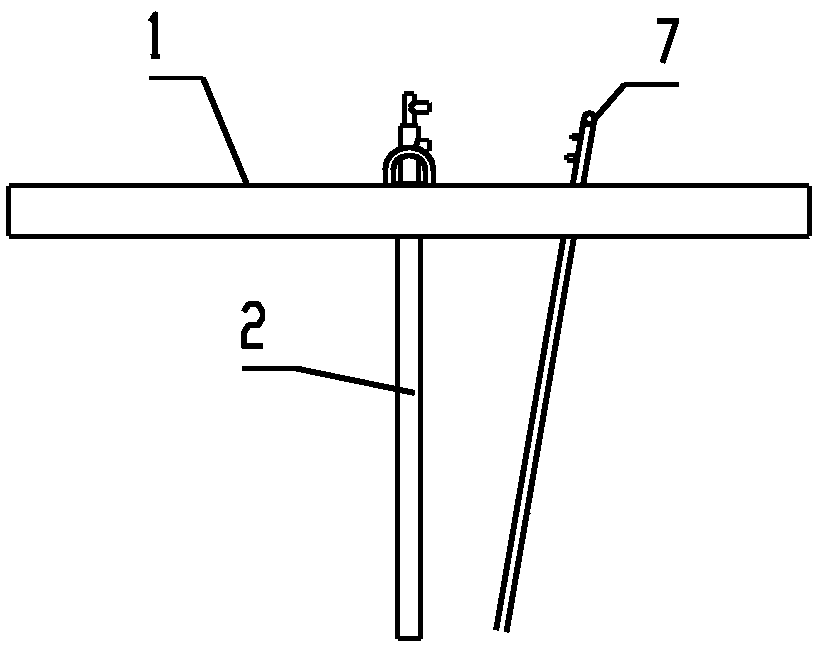

High-efficiency intelligent steel ladle baking device and application method thereof

A baking ladle and intelligent technology, which is applied in the direction of casting melt containers, metal processing equipment, casting equipment, etc., can solve the problems of not meeting the high-quality requirements of ladle heaters, long baking time, and uneven heating, so as to save gas, Fast heating speed and uniform heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

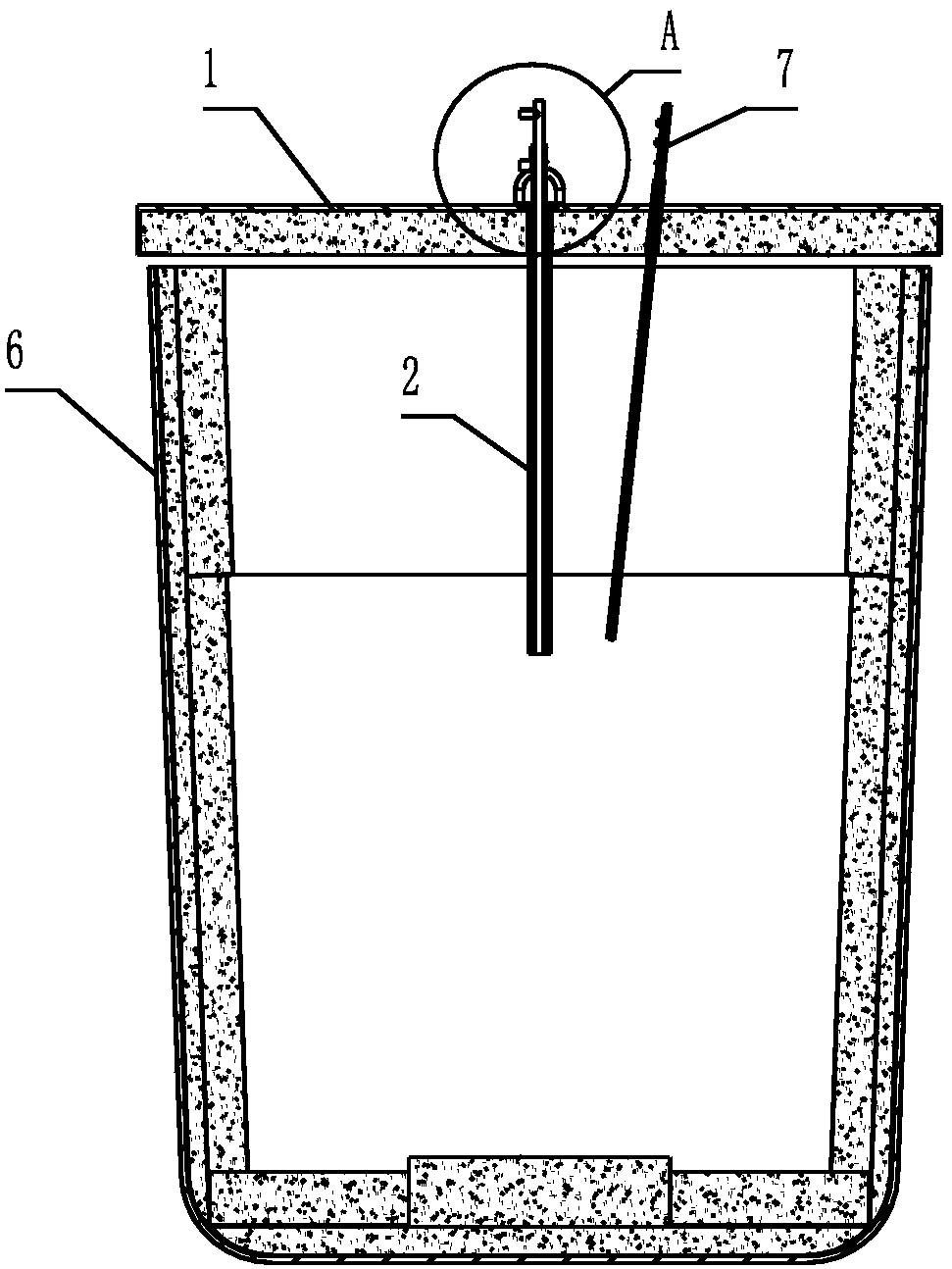

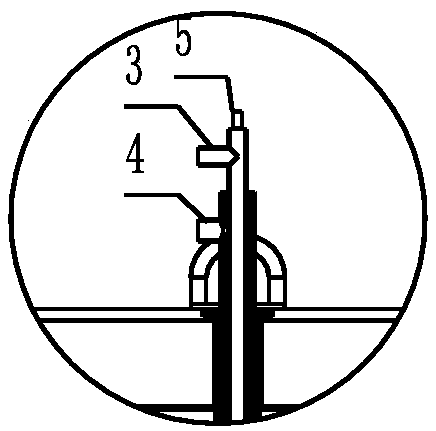

[0044]Embodiment 2: A high-efficiency intelligent baking bag device, the burner can be fixed on the cover with an adjustable height, and the adjustment method is a combination of airtight screws and screw holes. During the baking operation, the distance between the combustion head and the bottom of the ladle can be adjusted. It can be adjusted to meet the needs of ladles with different depths, and can also flexibly adjust the upper and lower positions of the combustion head when heating. The burner is provided with sub-combustion heads, the sub-combustion heads are arranged at different heights in the axial direction of the burner, and are respectively provided with one 200mm and 400mm away from the combustion head. Rotating on the axis, the combustion head can heat the ladle walls at different heights and positions at the same time during the ladle baking operation, so as to increase the heating speed and reduce the heating time. Other structures of this embodiment are the sa...

Embodiment 3

[0046] Embodiment 3: A high-efficiency intelligent baking device is provided with a movable thermocouple embedded in the refractory block. The thermocouple is placed on the inner wall of the ladle during the baking operation to detect the temperature of the bag wall during the baking process. change; pressure sensors and flow sensors are provided on the pipelines that communicate with the air source, oxygen source, gas source and the air inlet of the burner respectively, and a booster pump and a controllable booster pump opening and closing and speed control are provided. Automatic control frequency converter; in addition, a PLC controller is provided, and the PLC controller is connected with the pressure sensor, flow sensor, self-control switch, self-control frequency converter and the thermocouple for signal and control; its control mode is: PLC controller According to the temperature information obtained from the thermocouple and the preset adjustment data of the correspondi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com