Air thermalization gas burner

A technology of gas burners and burners, which is applied in the direction of gas fuel burners, burners, gaseous heating fuels, etc., which can solve the problems of wasting resources, insufficient carbon monoxide and nitrogen oxides, and increasing the amount of gas consumption, so as to eliminate harm to the human body Health hazards, carbon monoxide suppression, and energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

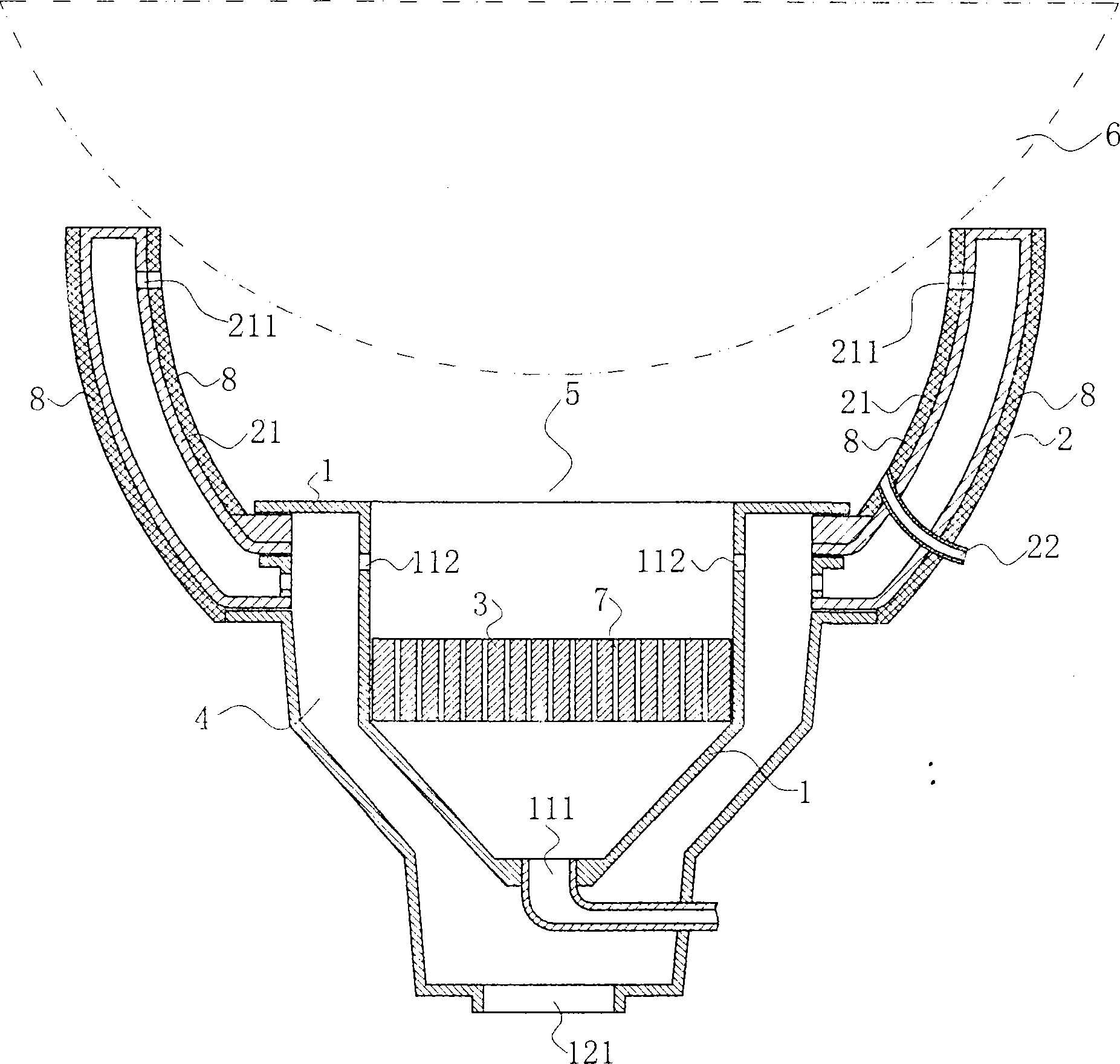

[0014] As shown in the accompanying drawings, the air heating gas burner includes a burner seat 1, on which a hob 2 for placing a wok 6 is fixedly installed, and inside the burner seat 1 is fixedly installed a Combustion head 3 with several atomization holes 7, several atomization holes 7 are evenly arranged on the combustion head 3, so that the gas can achieve the best atomization effect, so that the gas can be fully combusted, the bottom of the burner seat 1 There is an air supply port 111 connected to the gas pipeline, and the burner seat 1 is provided with a number of air injection ports 112 for supplying the combustion aid of the combustion head 3, and the outer side of the burner seat 1 is provided with the air injection port 112 connected to the air supply channel 4, the air supply channel 4 is provided with a blower air inlet 121, the shell of the air supply channel 4 covers the burner seat 1, so that the burner seat 1 can be used to heat the blower blower The incoming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com