Local heater used in molding of pipe orifice of main steam super pipe and method for heating master pipe blank by using same

A super pipe and main steam technology, which is applied in the field of local heaters and their heating parent pipe blanks, can solve the problem that the quality is difficult to meet the requirements of the working conditions of nuclear power, and can prevent large deformation, reduce fuel consumption, and heat evenly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

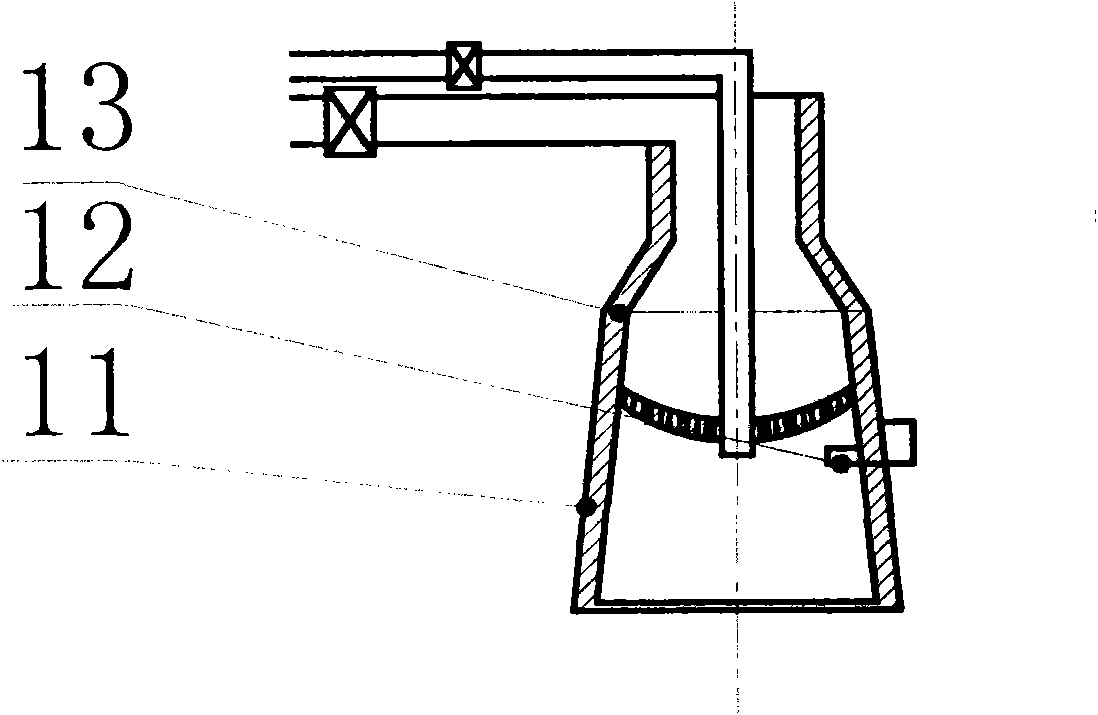

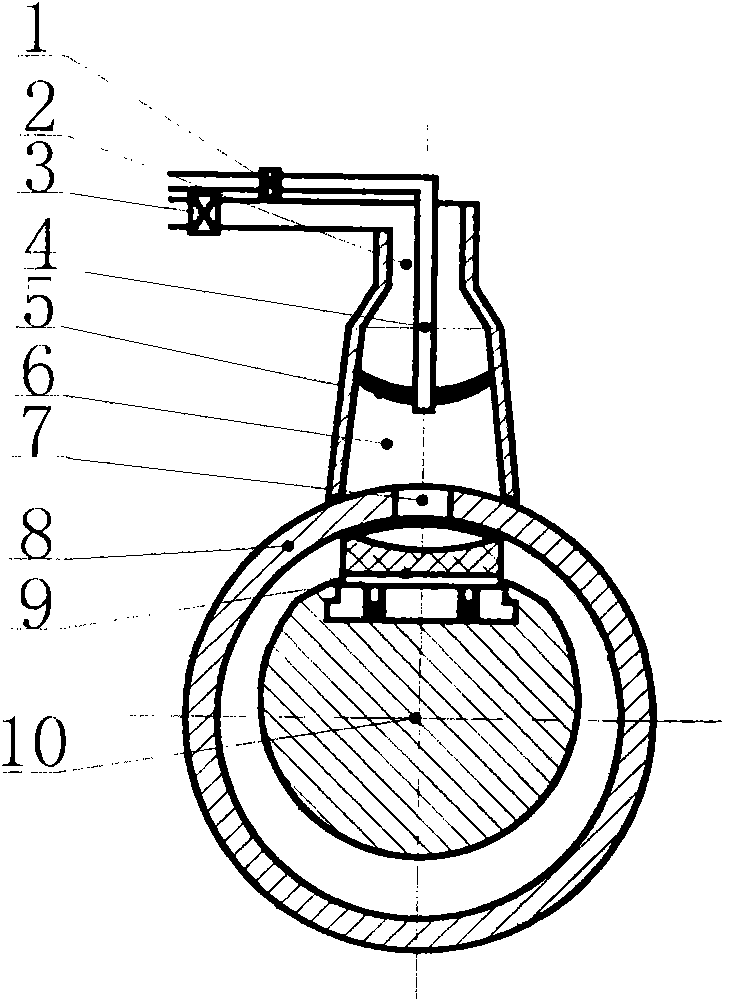

[0016] refer to figure 1 , 2 3. The main steam super pipe nozzle molding local heater of the present invention is composed of a burning head and a fire baffle plate. The combustor 6 of the burning head part has the air intake pipeline 2 and the combustible gas intake pipeline 4 which communicate with the air source and the combustible gas source. The contact surface between the chamber and the heated main steam super pipe mother pipe blank is a curved surface.

[0017] Movable fire baffle plate 9 is placed on the rolling bearing of the special support rod 10 in the main steam super pipe parent pipe blank 8, and the movement of the fire baffle plate on the special support rod is realized by the rolling of the rolling bearing.

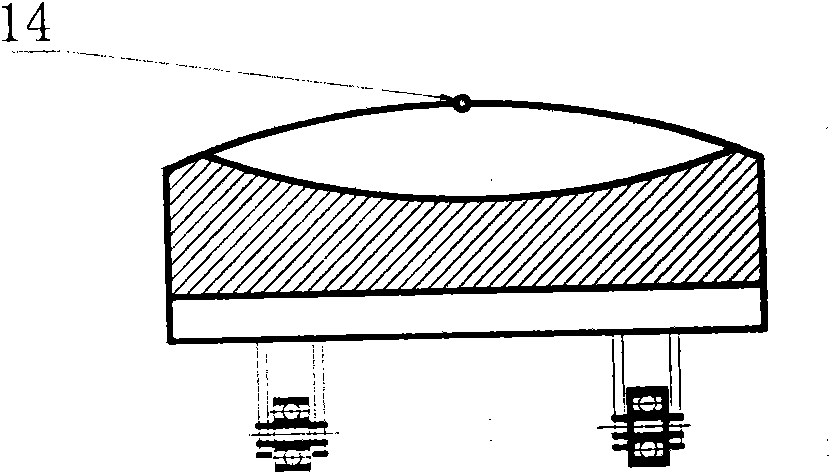

[0018] There is a contact thermocouple 14 in contact with the main steam super pipe parent pipe blank on the fire baffle plate, and the contact thermocouple is in contact with the inner wall of the pipe, which can display the temperature of the heated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com