Full-premix burner

A burner and fully premixed technology, which is applied in the direction of burners, gas fuel burners, and combustion methods, can solve the problems of high processing cost, high design difficulty, and insufficient local gas mixing, so as to prolong the service life and reduce the Energy loss, effect of accelerated mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

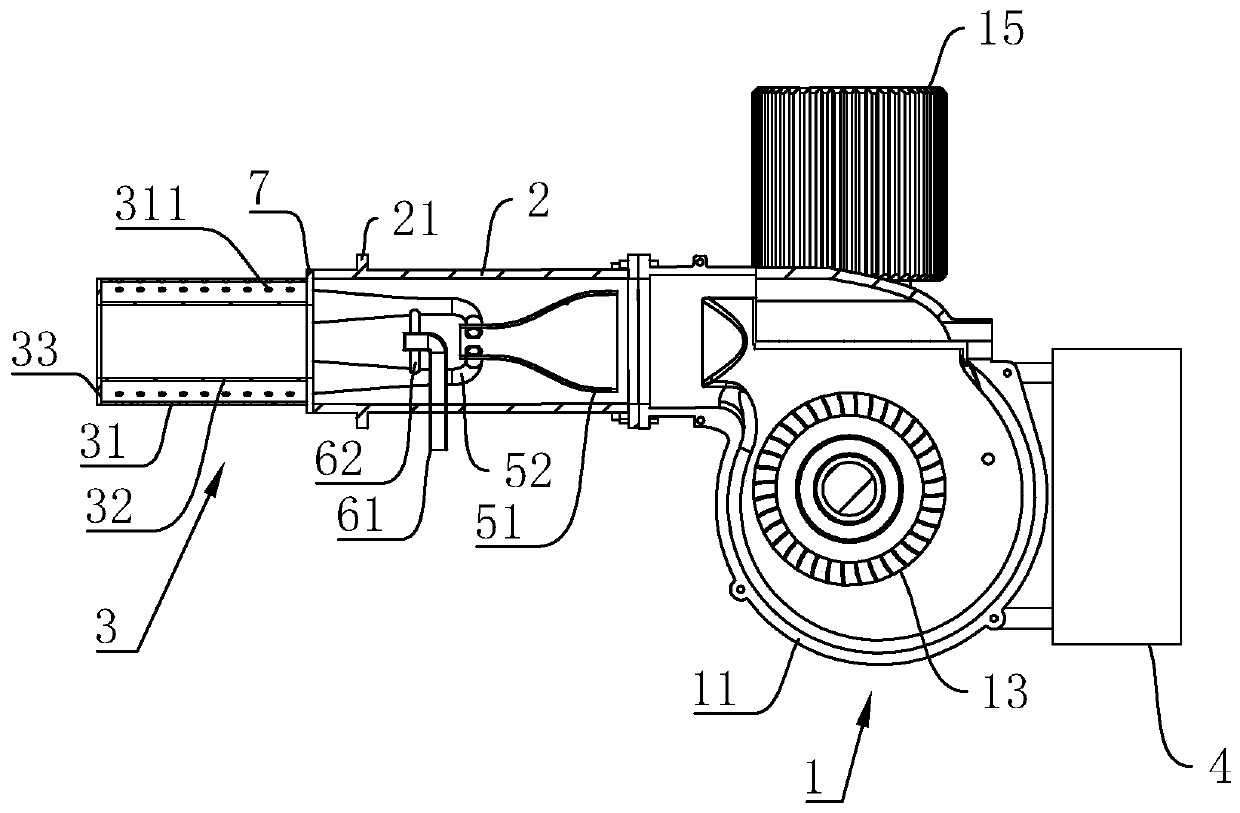

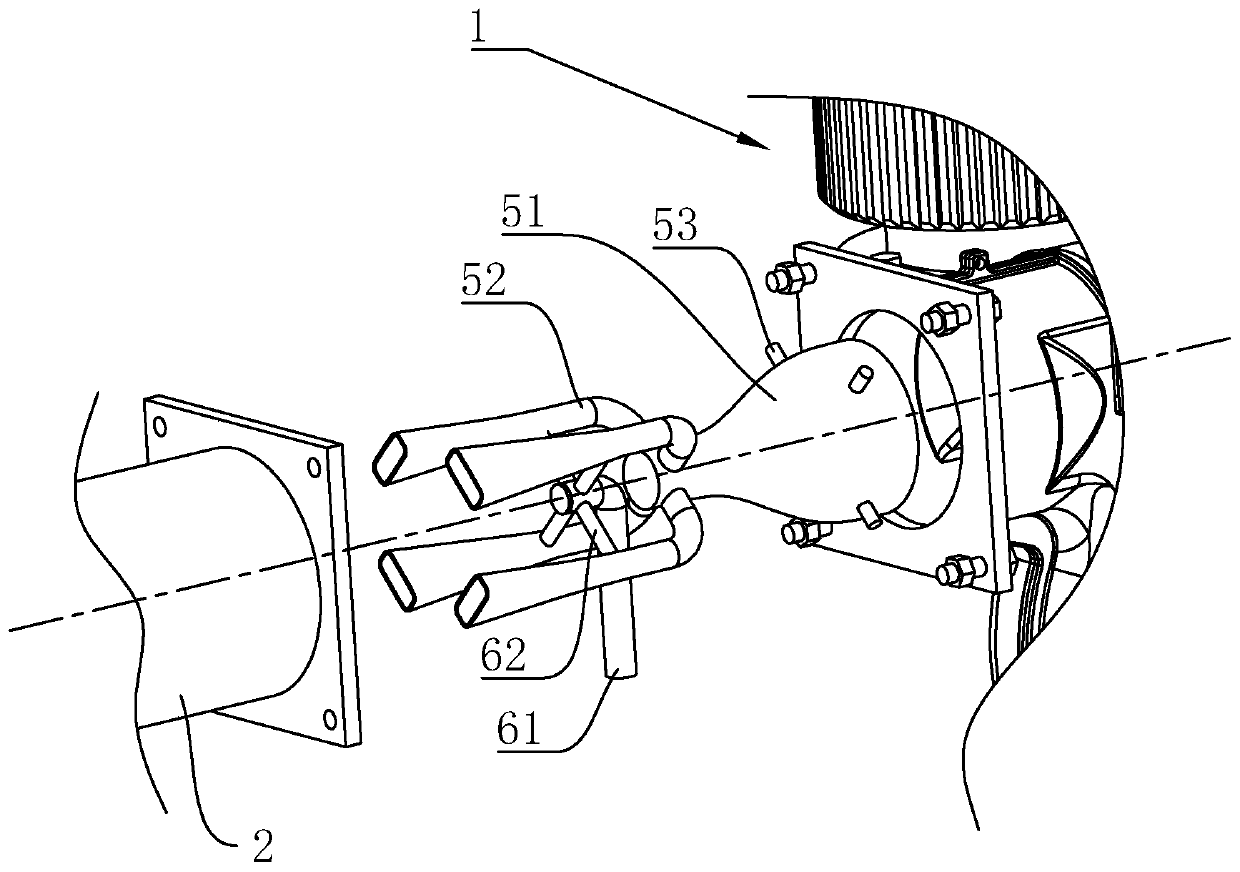

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

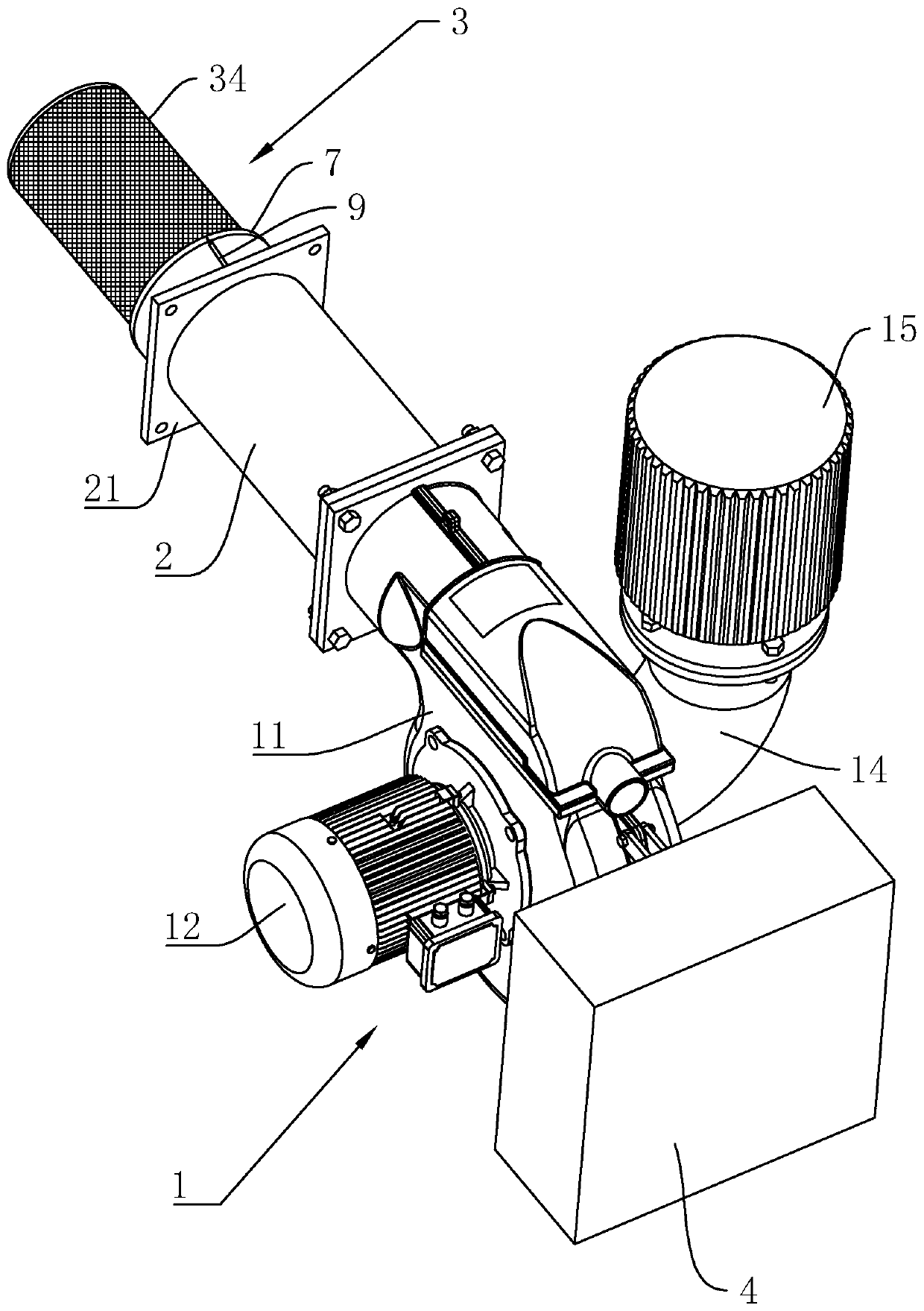

[0035] see figure 1 , the invention discloses a fully premixed burner, including a fan 1, a mixing chamber casing 2, a combustion head 3 and an electric control box 4. The mixing chamber housing 2 is located between the fan 1 and the combustion head 3 . The electric control box 4 is fixed on the side of the casing 11 away from the mixing chamber casing 2 .

[0036] The fan 1 includes a casing 11 , a motor 12 outside the casing 11 , and an impeller 13 inside the casing 11 . The motor 12 is fixedly connected to the casing 11 through bolts, and the motor 12 is electrically connected to the electric control box 4 . The output shaft of the motor 12 penetrates into the casing 11 and is rigidly connected with the impeller 13 coaxially, and the output shaft of the motor 12 is connected with the casing 11 in rotation. The blower 1 also includes an air intake pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com