Blade angle adjustable four-channel whirl pulverized coal burner

A pulverized coal burner, blade angle technology, applied in the direction of burners, burners burning powder fuel, combustion methods, etc., can solve problems such as difficult, uncontrollable units, difficult to control the combustion state, etc., to achieve convenient operation, structure Reasonable, quality-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

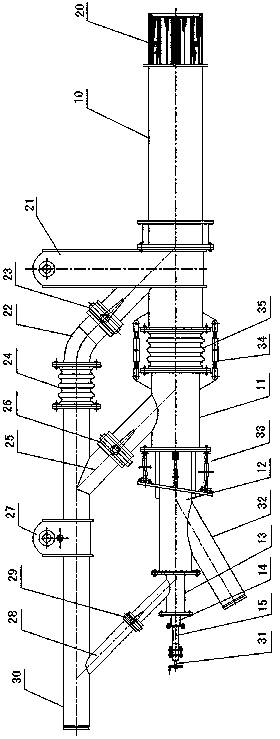

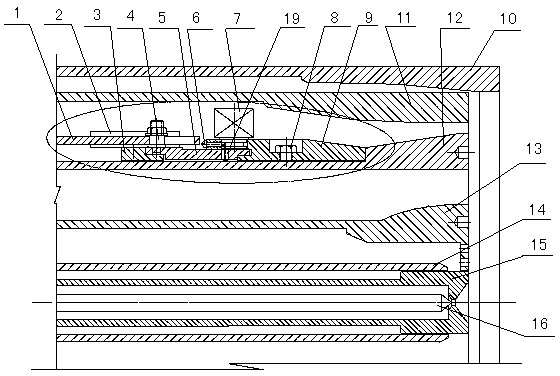

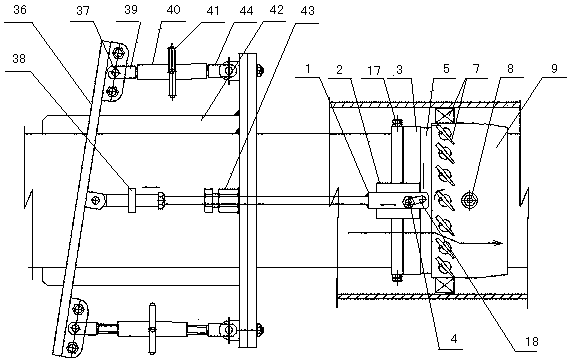

[0017] Such as figure 1 As shown, a four-channel air supply device composed of a DC air duct 10, a DC air duct 11, a swirl air duct 12, a coal air duct 13, a central air duct 14 and a main air inlet duct 30 is made of metal materials. With the main air inlet pipe 30, the central air inlet pipe 28 connecting the central wind air duct 14, the swirl air inlet pipe 25 connecting the swirl air air pipe 12, the direct current air inlet connecting the direct current wind air pipe 11 are set on the independent air inlet pipe 30. Air duct 22, and central air valve 29 is set on central air inlet pipe 28, swirl air valve 26 is set on swirl air inlet pipe 25, DC air valve 23 is set on DC air inlet pipe 22, and coal wind air duct 13 is A coal air inlet pipe 32 is set, and a flame cover adjusting device 34 and a telescoping pipe 35 are set on the four-channel air supply device pipeline simultaneously, and a combustion head 20 is arranged at the front end of the four-channel air supply devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com