Injection impeller burner

A burner and injection technology, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of low combustion thermal efficiency, high exhaust gas emissions, insufficient and uniform mixing of gas and injected air, etc. , to achieve good effect, improve combustion heat efficiency, easy manufacture and application promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

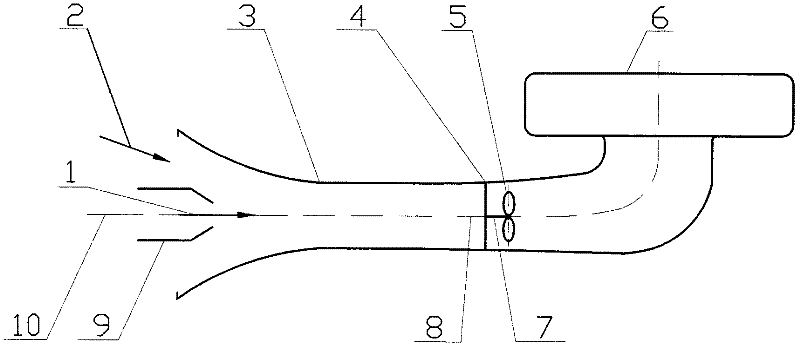

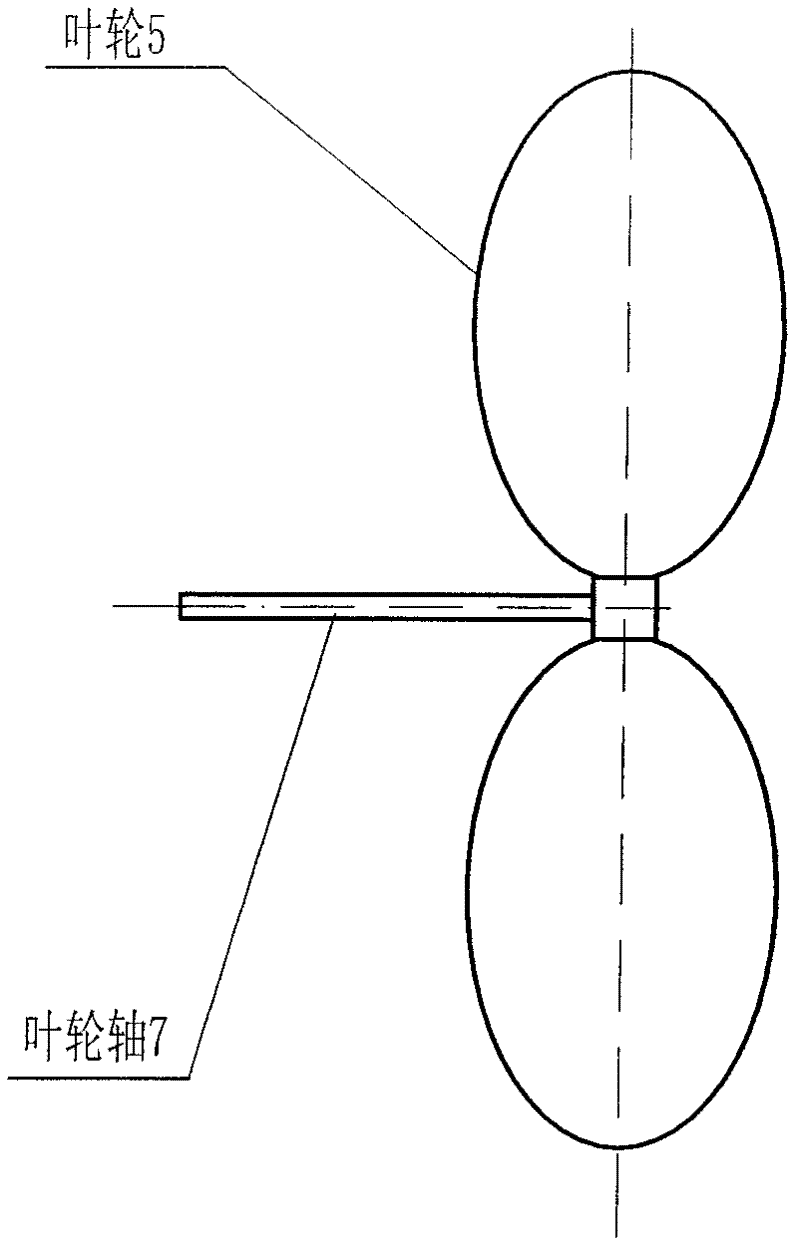

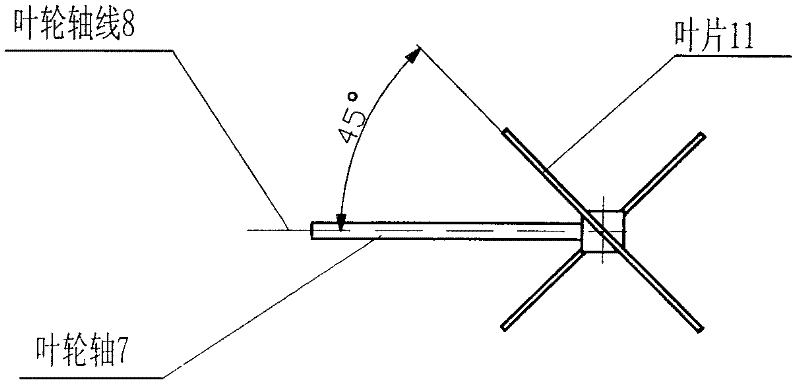

[0018] like figure 1 , figure 2 , image 3 As shown, the injection impeller burner includes a nozzle 9, an injection pipe 3, an impeller 5 and a combustion head 6. A shaft support 4 is arranged inside the injection pipe 3, and an impeller shaft 7 is arranged on the shaft support 4. The impeller shaft 7 is provided with an impeller 5, the impeller 5 can rotate freely relative to the shaft support 4, the injection tube 3 is fixedly connected to the shaft support 4, and the included angle between the blade 11 on the impeller 5 and the impeller axis 8 is 45° °, the impeller axis 8 coincides with the centerline 10 of the ejector tube.

[0019] Two impellers 5 may be arranged on the impeller shaft 7 .

[0020] The shaft support 4 can be repeatedly provided at intervals in the injection tube 3 , the shaft support 4 is provided with an impeller shaft 7 , and the impelle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com