Natural gas cold flame horizontal type fire tube steam boiler

A steam boiler and natural gas technology, applied in fire tube steam boilers, water tube steam boilers, steam boilers, etc., can solve the problems of reducing the service life of steel pipe economizers, reducing boiler energy efficiency, and large smoke pressure head, etc., to achieve automatic The effect of stable and continuous water supply, saving the space occupied by the furnace, and convenient maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

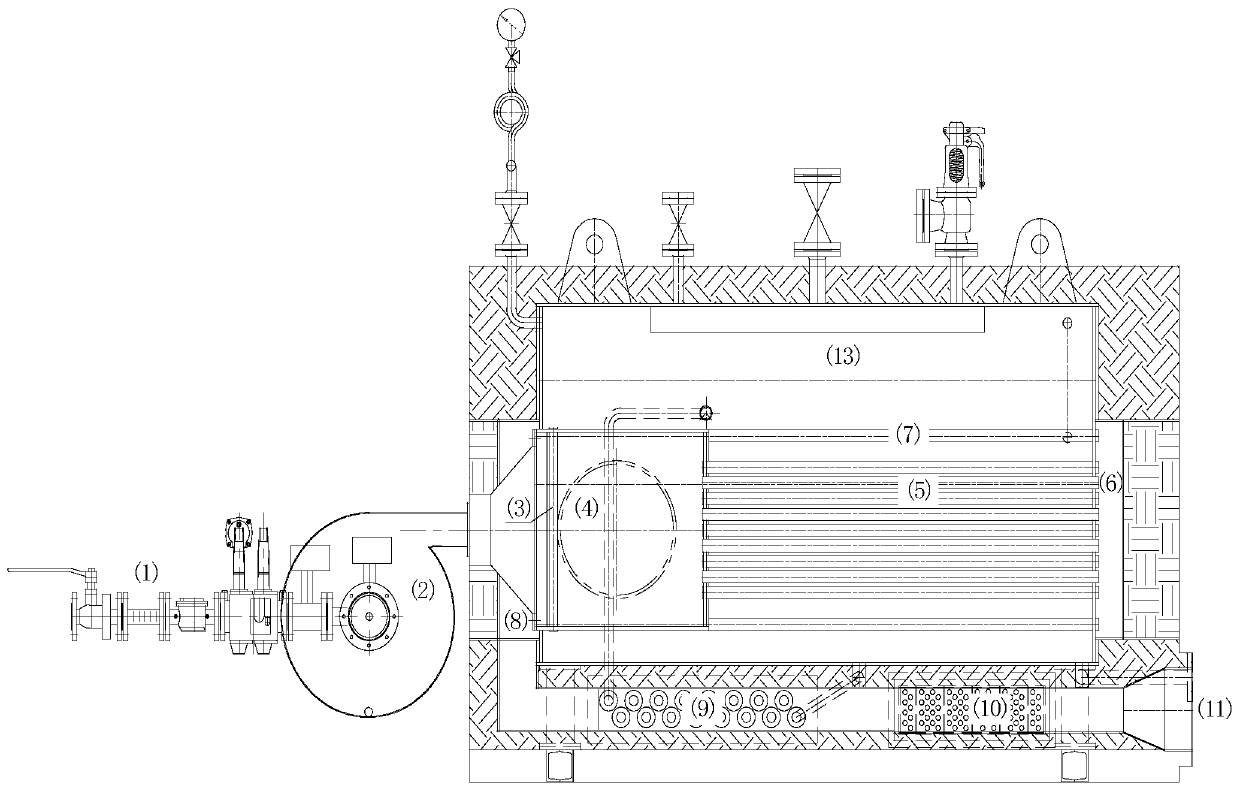

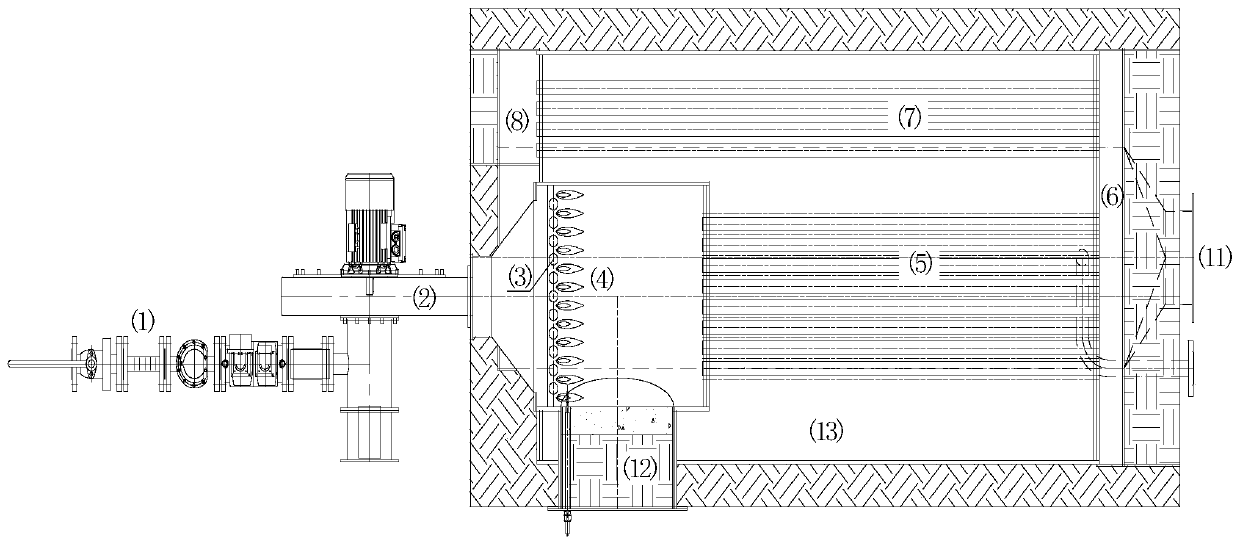

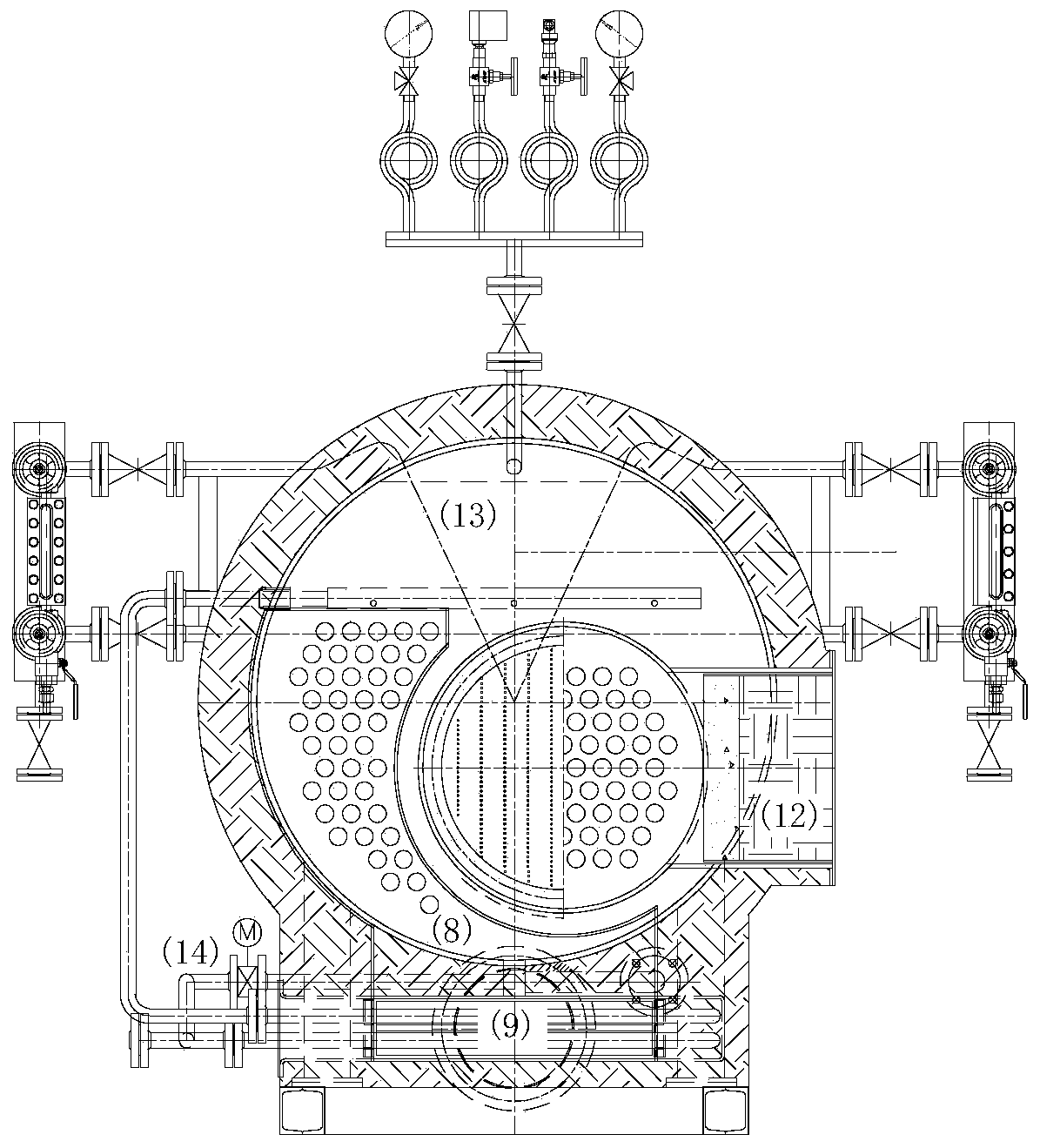

[0022] Refer to attached Figure 1-4 , the specific implementation manners of various objects of the present invention are as follows:

[0023] The main purpose of the present invention is achieved in this way: as shown in the accompanying drawings, a natural gas cold flame combustion horizontal fire tube steam boiler is provided, which mainly consists of a gas valve group (1), an explosion-proof fan (2), a cold flame combustion head ( 3), furnace (4), threaded flue pipe for primary return (5), rear smoke box (6), threaded flue pipe for secondary return (7), turning smoke chamber (8), economizer (9), condenser (10 ), smoke outlet (11), furnace inspection door (12), pot shell (13), recirculation pipeline (14), etc.

[0024] Cold flame combustion technology: fully mix a slightly excessive amount of air and natural gas, and then inject the mixed gas into the furnace at high speed through the cold flame combustion head (3) for combustion.

[0025] Wherein the structure of the cold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com