Process for production of fine cellulose fiber dispersion

A technology for fine cellulose and cellulose fibers, which is applied in the field of manufacturing fine cellulose fiber dispersions, can solve the problems of difficulty in adjusting the composition ratio of resin and cellulose fibers, difficulty in separately manufacturing composites, and complicated manufacturing processes, and achieves liquid stability. Excellent properties, excellent film-forming properties and moldability, and good production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0298] Hereinafter, the present invention will be described more concretely by way of production examples, examples, and comparative examples, but the present invention is not limited to the following examples unless the gist thereof is exceeded.

[0299] The measurement methods of various physical properties of the fine cellulose fiber dispersion liquid and the cellulose fiber composite are as follows.

[0300] [Dispersion stability test of fine cellulose fiber dispersion]

[0301] The fine cellulose fiber dispersion was prepared, and the presence or absence of sedimentation immediately after the preparation and after standing at room temperature for 10 days was visually evaluated according to the following criteria. "No sedimentation observed at all" was marked as AA, "almost no sedimentation was observed" was marked as A, "settling was slightly observed, or aggregation was observed in a part of the dispersion" was marked as B, and "observed Very much settling, or aggregate...

manufacture example 1

[0317] Wood flour (Miyashita Wood, Measong 100, particle size 50 to 250 μm, average particle size 138 μm) was degreased with a 2% by weight sodium carbonate aqueous solution at 80° C. for 6 hours. After washing with deionized water, delignification was performed at 80° C. for 5.5 hours using sodium chlorite under acidic acetic acid. After washing this with deionized water, it was immersed in a 5% by weight potassium hydroxide aqueous solution for 16 hours to perform a dehemicellulose treatment. This was washed with deionized water to obtain cellulose fibers (number average fiber diameter: 60 μm).

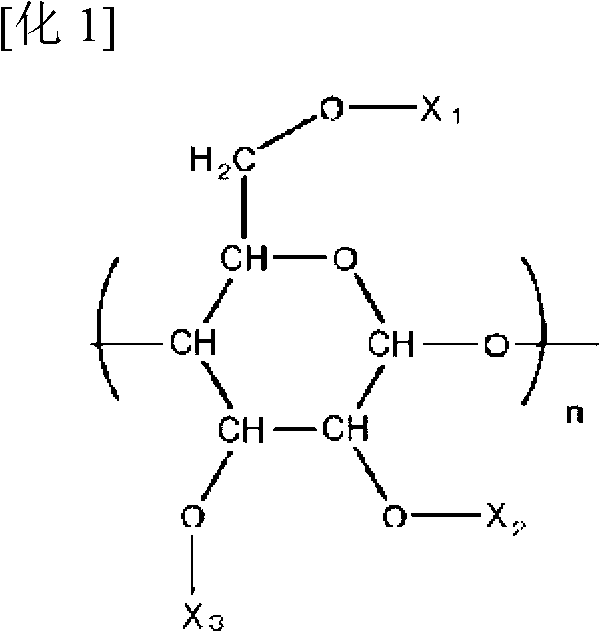

manufacture example 2

[0319] In Production Example 1, the cellulose fibers subjected to the dehemicellulose treatment and washed with deionized water were dehydrated by filtration. This was dispersed in acetic acid and filtered, and this filtration step was performed three times to replace water with acetic acid. 25 ml of toluene, 20 ml of acetic acid, and 0.1 ml of a 60% perchloric acid aqueous solution were mixed, and 1 g of cellulose fibers substituted with acetic acid was added to the mixture, followed by 1.3 ml of acetic anhydride, and the reaction was carried out for 1 hour while stirring. After the reaction, the reaction solution was filtered and washed with methanol and deionized water in sequence.

[0320] The chemical modification rate of the obtained acetylated cellulose fibers was calculated based on the above-mentioned measuring method of the chemical modification rate and found to be 16 mol%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com