Metal working oil, method of metal working, and prodeuct of metal working

A technology of metal processing and oil agent, which is applied in the direction of additives, petroleum industry, transportation and packaging, etc. It can solve the problems of being easily hydrolyzed, the oil agent cannot be fully lubricated, and the defoaming property is poor, so as to improve the metal processing property and reduce the The number of tool change processes and the effect of low dynamic viscosity

Inactive Publication Date: 2012-06-13

KYODO YUSHI CO LTD

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] However, these oils for metal processing have problems such as insufficient lubrication, poor defoaming properties, and easy hydrolysis.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

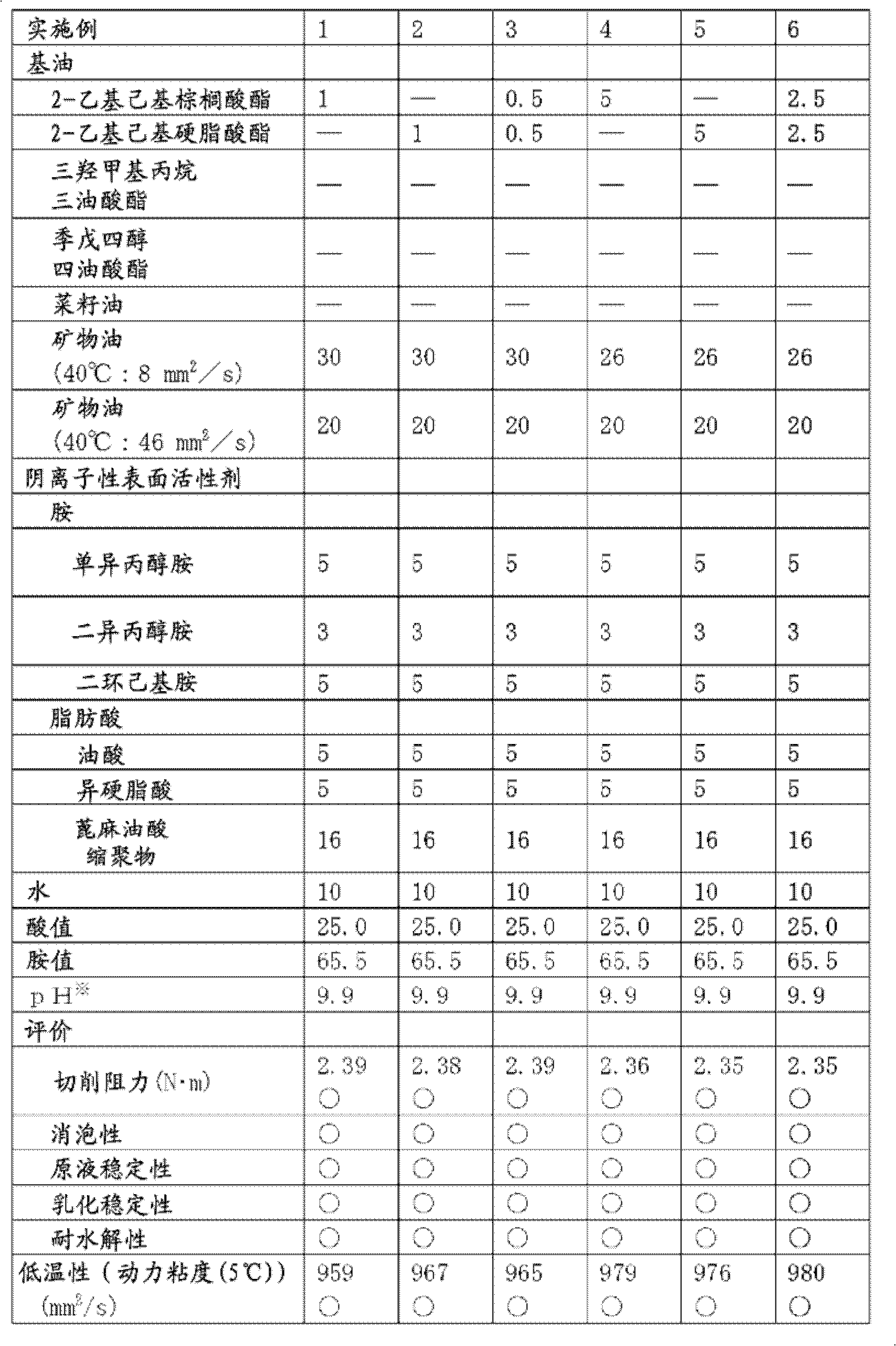

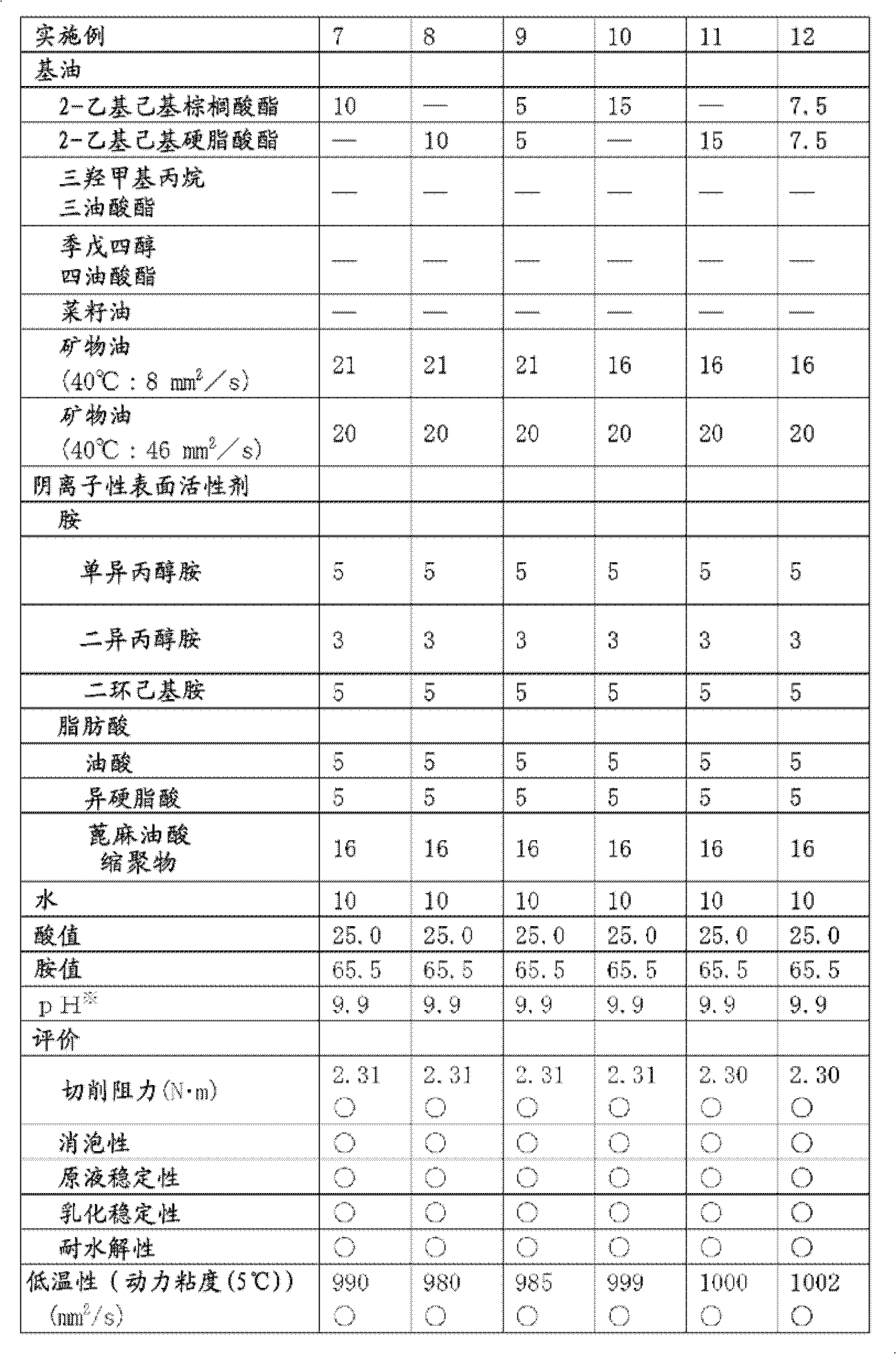

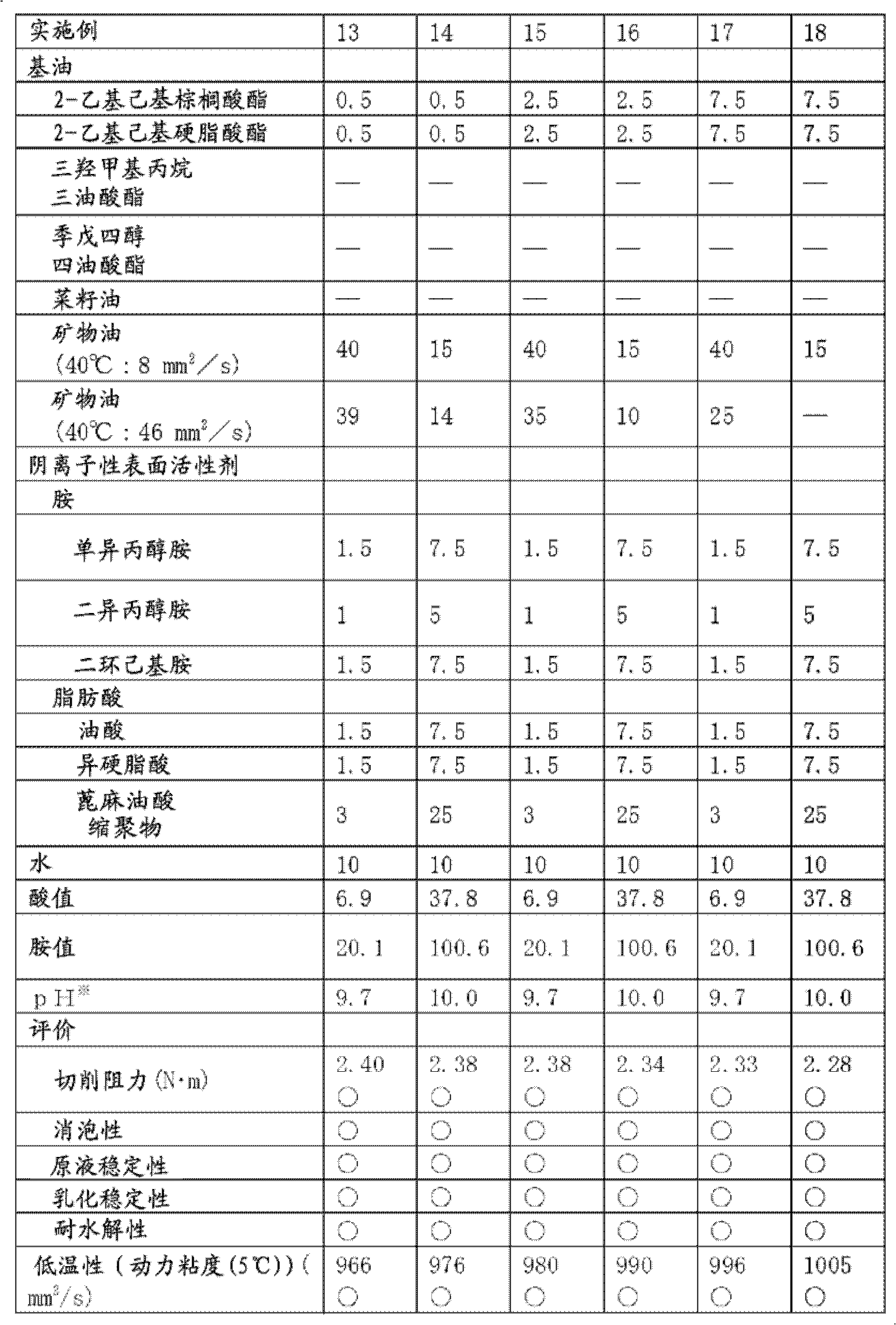

[0054] Tables 1-4 show metalworking oils of Examples and Comparative Examples. Each metalworking oil agent was evaluated by the following test method. The results are shown in Tables 1-4 together.

[0055] The numerical value in the component column in a table|surface shows the mass % of each component in a stock solution.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

Provided is a metal working oil which comprises (A) a base oil comprising 2-ethylhexanol palmitate or stearate and (B) an anionic active agent comprising a salt of a C8-18 branched aliphatic carboxylic acid with a C3-12 branched alkanolamine. The metal working oil has excellent suitability for cutting, less-foaming properties, concentrate stability, emulsion stability, and hydrolytic resistance and has low dynamic viscosity at low temperatures.

Description

technical field [0001] The present invention relates to an oil agent for metal processing that can be widely used in metal processing such as cutting processing, grinding processing, rolling processing, stamping processing, and plastic processing. In more detail, it relates to a metalworking oil used by diluting it with water, especially a metalworking oil excellent in machinability, a metalworking method using the metalworking oil, and a metalworked product produced by the metalworking method . Background technique [0002] Generally, cutting and grinding oils are used in cutting and grinding processes. The most important function of cutting and grinding oils is the lubricating effect, which can improve the life of the tools used in processing, improve the surface accuracy of the workpiece, and improve productivity, etc., and can improve productivity. . In addition, regarding these required performances, studies have also been carried out from the processing method, and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M169/04C10M105/34C10M133/08C10N30/00C10N30/02C10N30/18C10N40/20C10N40/22

CPCC10M2207/281C10M2203/1006C10M2207/2835C10M2207/126C10M2215/042C10N2230/02C10N2230/18C10M173/00C10M2207/401C10N2230/26C10M2207/283C10M2207/2815C10N2240/401C10M169/04C10M2209/102C10N2230/66C10M2215/0425C10N2230/24Y10T29/49Y10T428/12Y10T83/0443C10N2030/02C10N2030/18C10N2030/24C10N2030/26C10N2030/66C10N2040/22

Inventor 后藤孝一美马聪志町田善彦

Owner KYODO YUSHI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com