Water based antistatic releasing coating composition and antistatic releasing film

An antistatic and coating agent technology, applied in conductive coatings, antifouling/underwater coatings, coatings, etc., can solve the problem of stability (poor liquid stability, poor dispersion and dissolution of conductive Solvent degradation and other problems, to achieve excellent solvent resistance, excellent liquid stability, light peeling force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

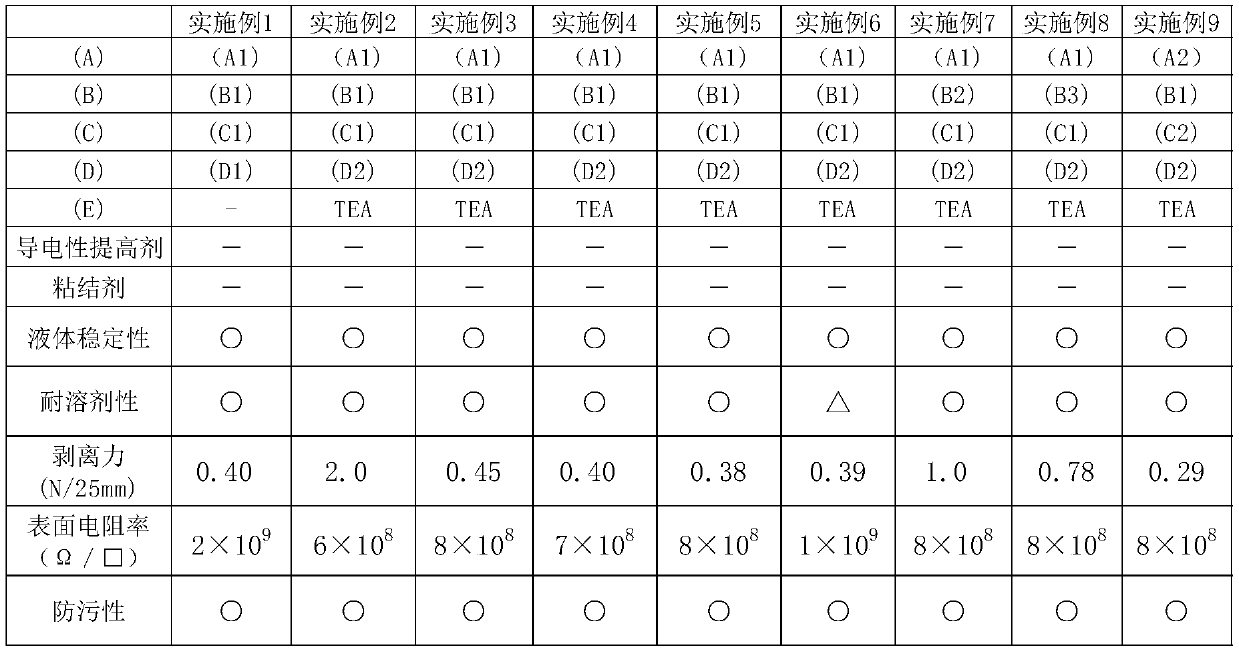

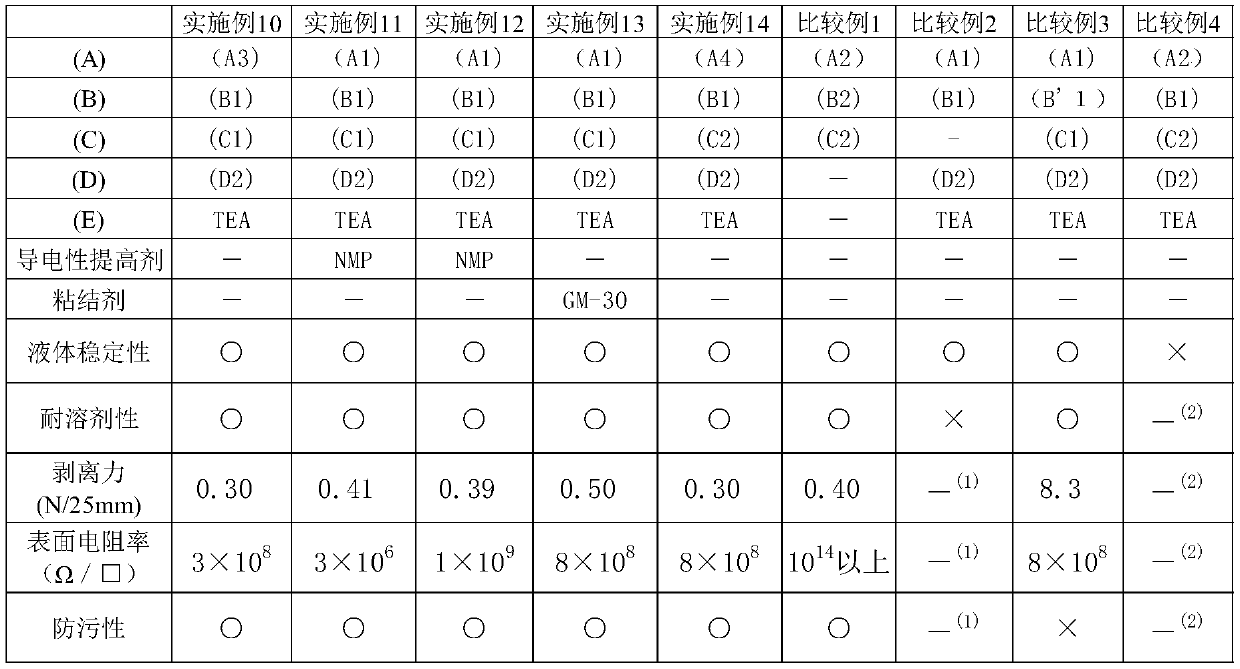

Embodiment 1

[0085] 11.4 parts by weight of NIKALAC MX-035 (manufactured by Sanwa Chemical Co., Ltd. with a solid content concentration of 70% imino-methylol-type methylated melamine resin) (hereinafter referred to as component (A1)) as component (A) , 8 parts by weight of BYK-SILCLEAN 3720 (polyether-modified siloxane containing a hydroxyl group with a solid content concentration of 25% by BYK Chemie Japan Co., Ltd.) (hereinafter referred to as (B1) component) as the component (B), as (C) 1 part by weight of AP-8 (acid octyl phosphate solid content concentration 100% manufactured by Daihachi Chemical Industry Co., Ltd.) (hereinafter referred to as (C1) component) 1 part by weight, as (D) component aquaPASS- 01x (aqueous dispersion of 5% polyanilinesulfonic acid solid content concentration manufactured by Mitsubishi Chemical Co., Ltd.) (hereinafter, referred to as (D1) component) 40 parts by weight was mixed, and it was mixed with 550 parts by weight of water and 550 parts by weight of isop...

Embodiment 2

[0087] 13.6 parts by weight of component (A1), 2 parts by weight of component (B1), 1 part by weight of component (C1), ORGACON ICP1010 (poly(3,4-ethylenedioxythiophene) and poly 83.3 parts by weight of aqueous dispersion of styrenesulfonic acid complex with a solid content concentration of 1.2% (manufactured by Japan AGFA Materials Co., Ltd.) (hereinafter referred to as component (D2)), 0.7 parts by weight of triethylamine as component (E) It was mixed and prepared by diluting 550 parts by weight of water and 550 parts by weight of isopropyl alcohol to a solid content concentration of 1%, thereby obtaining a coating agent.

Embodiment 3

[0089] In Example 2, (A1) component was changed into 13.9 weight part, (B1) component was changed into 4 weight part, and the coating agent was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com