Antistatic treating agent and preparation method thereof

A technology of antistatic treatment agent and conductive agent, which is applied in the field of antistatic treatment agent and its preparation, to achieve the effects of not being easy to agglomerate, improving antistatic ability, and broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

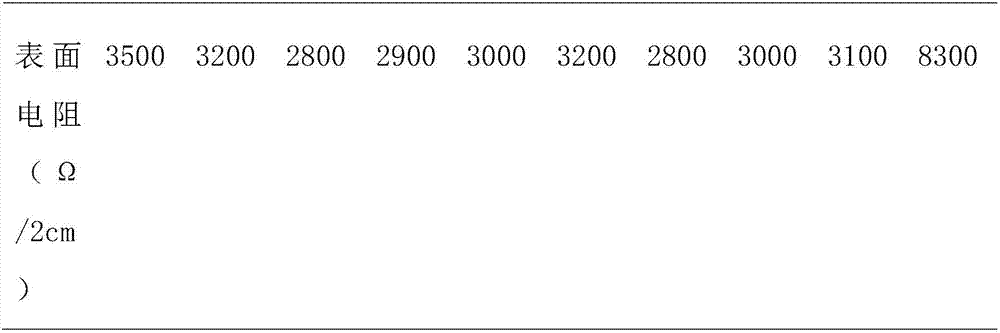

Examples

preparation example Construction

[0026] The embodiment of the present invention also provides a preparation method of an antistatic treatment agent, which mainly includes the following steps:

[0027] First, the graphite oxide is ultrasonically treated. Since a large number of oxygen-containing functional groups (such as hydroxyl and carboxyl) are inserted between the graphite oxide layers, the graphite oxide after ultrasonic treatment is easily peeled off, so that the graphite oxide is exfoliated into graphene oxide. Therefore, graphite oxide has the same chemical composition as graphene oxide, but the thickness of graphene oxide is smaller than that of graphite oxide. Therefore, graphene oxide has better electrical conductivity than graphite oxide. Of course, graphene oxide can also be purchased directly.

[0028] Then, the graphene oxide and the polymer polyol are added into the reaction kettle for stirring and mixing, and the stirring and mixing is carried out at 45-55°C. During this period, hydrophilic...

Embodiment 1

[0032] Raw material and quality used in this embodiment are as follows:

[0033] Polybutylene adipate neopentyl glycol ester diol (number average molecular weight 1000) 15g; polyadipate-1,4 butanediol ester diol (number average molecular weight 1000) 5g; triphenylmethane triisocyanate 5g ; Graphite oxide 0.1 g.

[0034] The preparation method of the antistatic treatment agent of the present embodiment is as follows:

[0035] Mix all the above-mentioned raw materials, keep the progress of the reaction at 50°C after mixing, judge the degree of progress of the reaction according to the change of the reaction solution, and finally obtain the antistatic treatment agent.

Embodiment 2

[0037] Raw material and quality used in this embodiment are as follows:

[0038] Polyethylene adipate diol (number-average molecular weight 3000) 10g; Polypropylene adipate diol (number-average molecular weight 1000) 5g; Polybutylene adipate diol hexanediol (number-average Molecular weight 2000) 13g; Triphenylmethane triisocyanate 8g; PPDI 14g; Graphite oxide 1g; Glycerol 0.3g; Pentanediol 0.5g; Deionized water 50g.

[0039] The preparation method of the antistatic treatment agent of the present embodiment is as follows:

[0040]Polyethylene adipate diol, polytrimethylene adipate diol, polybutylene adipate hexanediol diol, sodium sulfonate group-containing diol, carboxyl-containing polyester , Glycerin, Pentylene Glycol, and Graphite Oxide were put into the reaction kettle together, and stirred evenly at 45°C. Then slowly add the mixture of triphenylmethane triisocyanate and PPDI (the dropping rate is not limited), keep the temperature at 60°C for reaction, and after 3 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com