Phthalocyanine polymer, optical limiting device and preparation method therefor

A polymer and optical limiting technology, applied in optics, instruments, nonlinear optics, etc., can solve problems such as the aggregation of phthalocyanine compounds, and achieve the effect of improving mechanical stability, excellent mechanical strength and processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

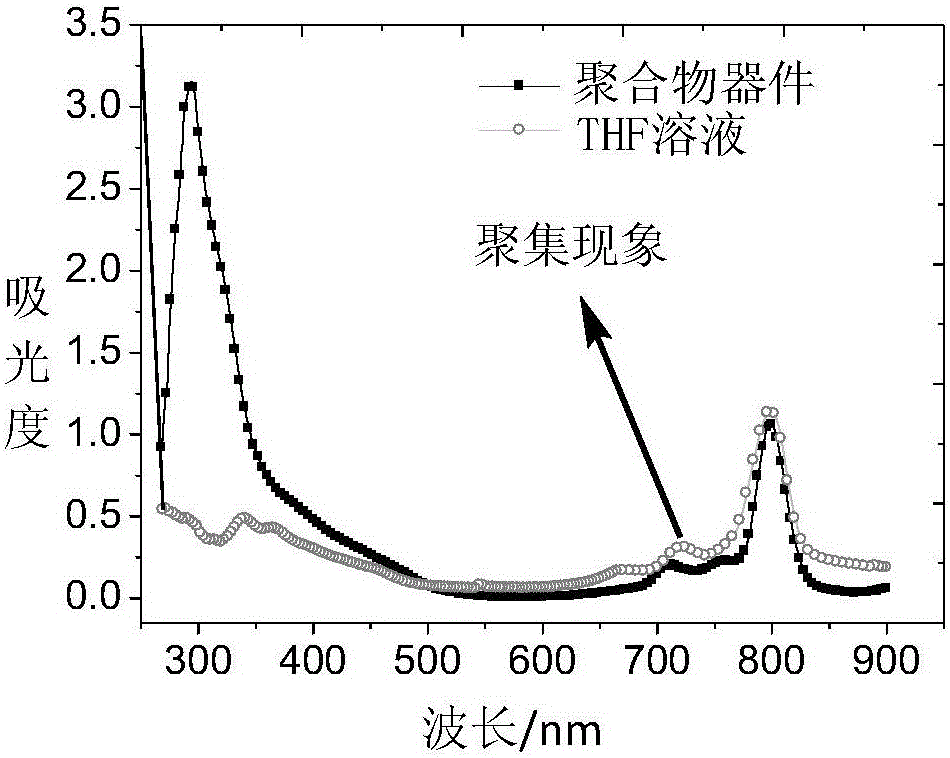

Problems solved by technology

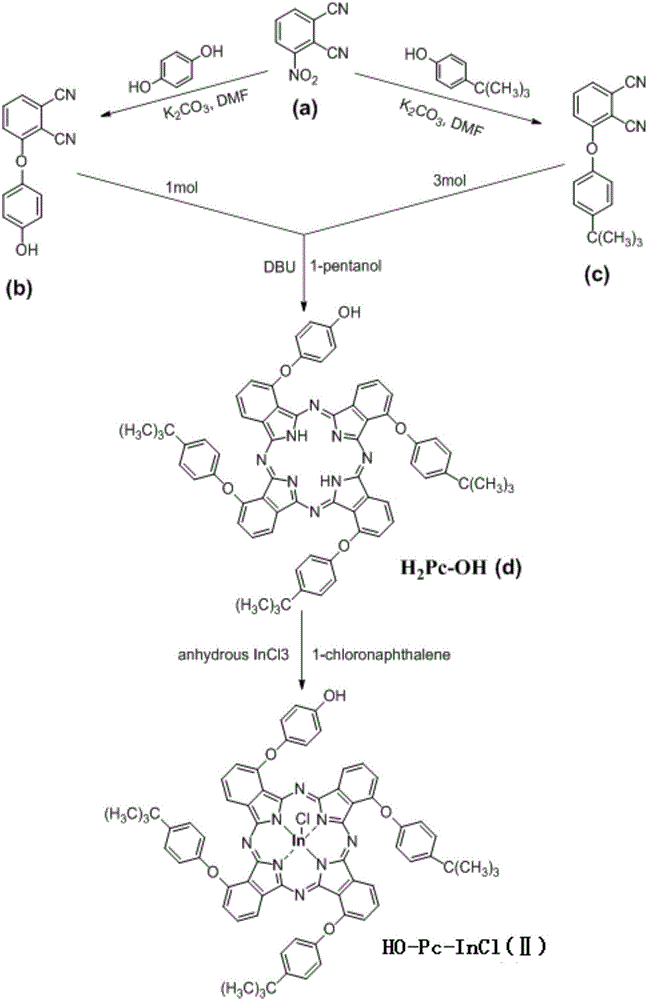

Method used

Image

Examples

Embodiment 1

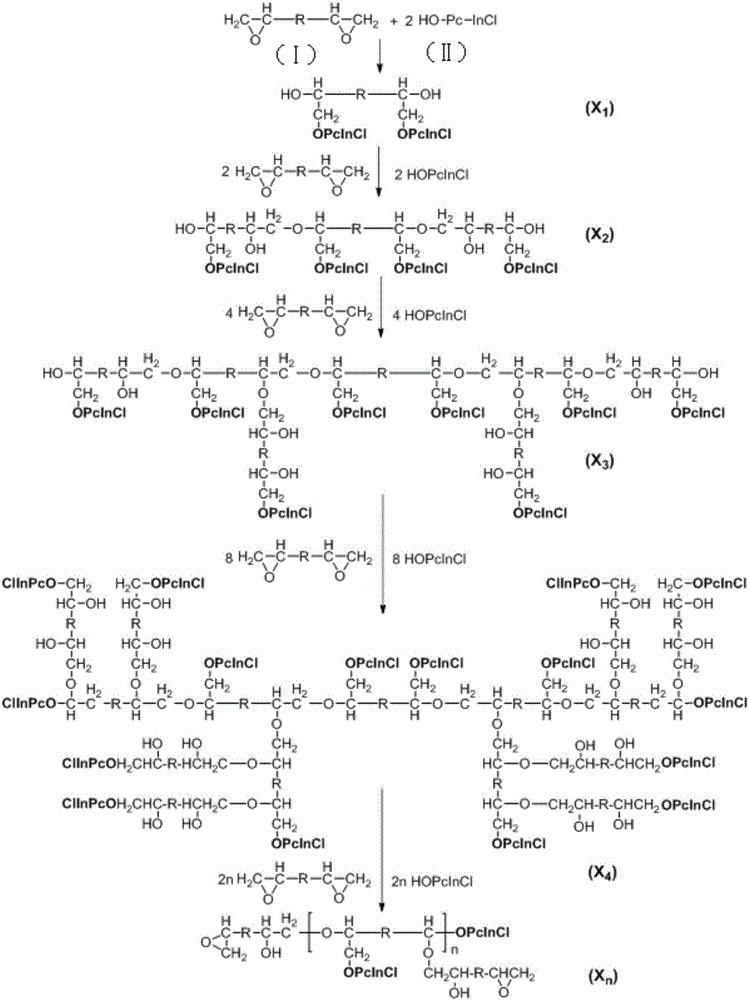

[0074] Add 1mol epoxy resin adhesive monomer (I) and 2mol asymmetric hydroxyl metal indium phthalocyanine compound (II) into a 500ml three-necked flask, add 200ml THF solution and stir until it is completely dissolved, then add 1mol NaOH, lower the temperature Rising to 100°C, stirring for 6 hours, cooling the mixture, and evaporating in vacuo to remove excess THF solvent to obtain metal phthalocyanine grafted epoxy resin prepolymer compound, namely phthalocyanine polymer (X 1 ), its structural formula is:

[0075]

Embodiment 2

[0077] Add 2mol of epoxy resin adhesive monomer (I) and 2mol of asymmetric hydroxyl metal indium phthalocyanine compound (II) to 1mol of phthalocyanine polymer (X 1 ) in THF solution, add 1mol NaOH solid particles, after fully mixing and stirring, heat up to 100°C, stir the mixture for 8h, cool the mixture, remove excess THF solvent by vacuum evaporation, and obtain phthalocyanine polymer (X 2 ), its structural formula is:

[0078]

Embodiment 3

[0080] Add 4mol of epoxy resin adhesive monomer (I) and 4mol of asymmetric hydroxyl metal indium phthalocyanine compound (II) to 1mol of phthalocyanine polymer (X 2 ) in THF solution, add 1mol NaOH solid, after fully mixing and stirring, heat up to 100°C, stir for 12h, then cool the mixture, remove excess THF solvent by vacuum evaporation, and obtain phthalocyanine polymer (X 3 ), its structural formula is:

[0081]

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com