Multi-fuel energy-saving environment-friendly range

An energy-saving, environment-friendly, multi-fuel technology, applied in the direction of biofuels, solid heating fuels, household stoves/stoves, etc., can solve the problems of not being able to guarantee that the fuel is completely usable, the combustion efficiency is not ideal, and the design is unreasonable, so as to solve the problem of cheap fuel problems, low fuel costs, operating environment and hygienic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

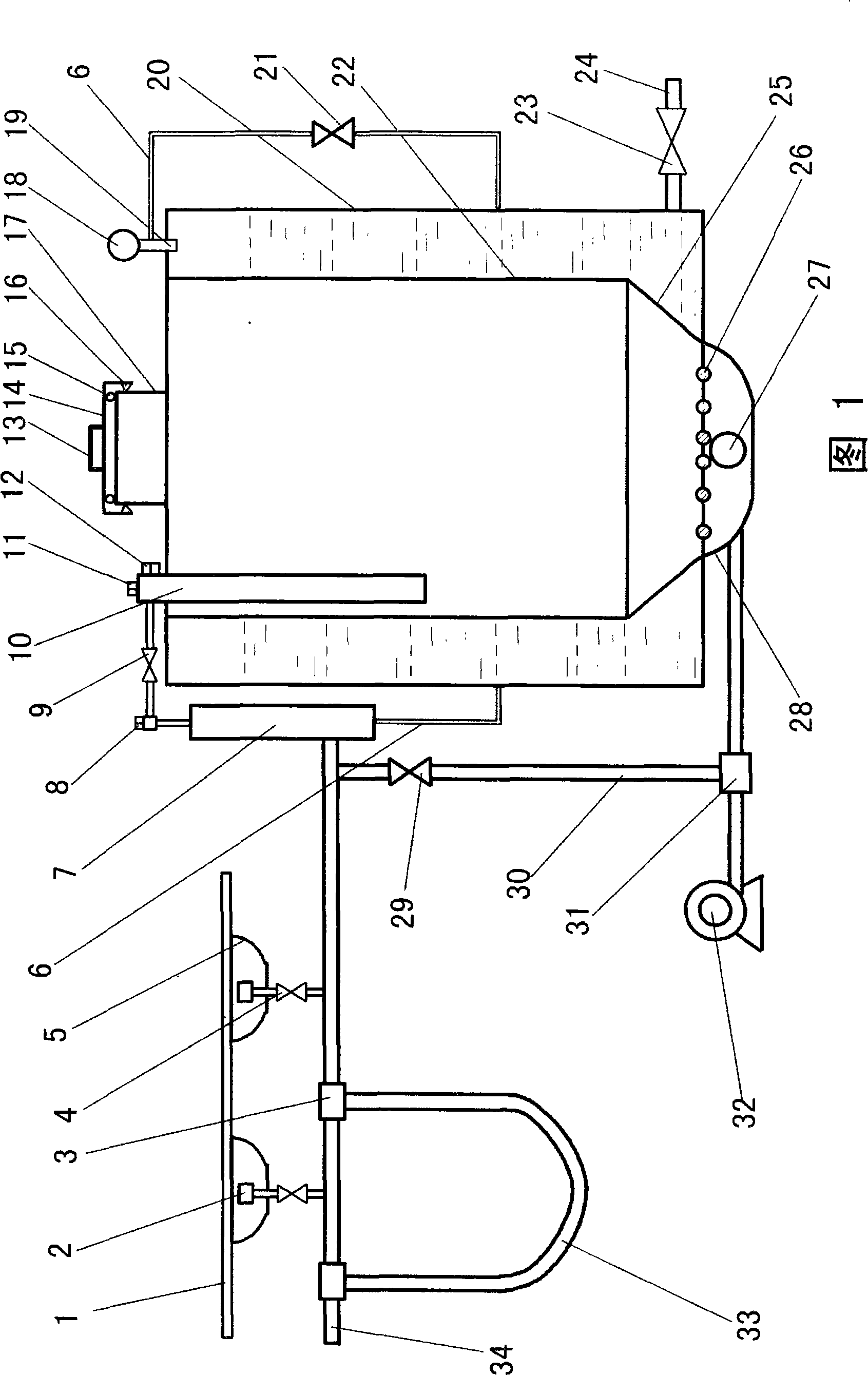

[0014] Referring to Fig. 1, the cross-section of the hearth of this energy-saving and environmentally-friendly stove changes, the upper section is a cylindrical furnace 22 of equal diameter, the lower section is a conical hearth 25 with a large upper part and a smaller lower part, and the cross-section of the ash storage chamber 28 is bowl-shaped. The curved surface is connected with the conical surface furnace 25 in a smooth transition. When the airflow from the fan is sprayed onto the bowl-shaped curved surface of the ash storage chamber 28, it rotates at a high speed and rises, and then guides the conical surface furnace 25 to guide the flow, and the air at the lower end of the entire cylindrical surface furnace 22 Uniform distribution, uniform burning on the same layer, no burning phenomenon. The inlet of the air duct 10 extends to the middle of the furnace, and most of the gas is in contact with the fuel on the upper part in a tortuous way, and a large amount of solid micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com