Pultrusion die for producing hybrid fiber reinforced polymer rod and preparation process

A hybrid fiber and pultrusion die technology, which is applied in the field of composite material processing, can solve the problem that low-strain fibers cannot be uniformly dispersed according to a preset method, and achieve the effects of avoiding uneven heating, reasonable design and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The pultrusion die used to produce hybrid fiber reinforced polymer rods in this example is not only suitable for preparing hybrid fiber reinforced polymer rods (including HFRP tendons, HFRP anchor rods and HFRP strands), but also suitable for preparing single fiber reinforced polymer rods. Polymer strands and cables, the reinforcement phase material for preparing hybrid fiber reinforced polymer rods can be composed of two or more reinforcement phases such as carbon fiber, glass fiber, aramid fiber, long synthetic fiber and steel strand, and the preparation of a single The reinforcing phase material of a fiber reinforced polymer strand and cable can be carbon fiber, glass fiber, aramid fiber, long synthetic fiber and steel strand, etc.; the matrix phase material for preparing a hybrid fiber reinforced polymer rod can be epoxy resin, Vinyl resin and unsaturated polyester resin, etc.

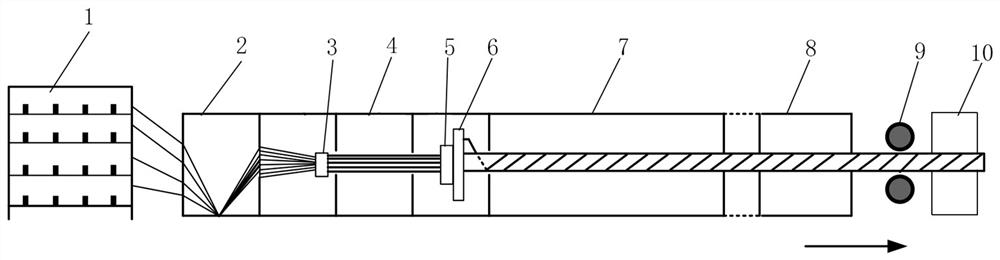

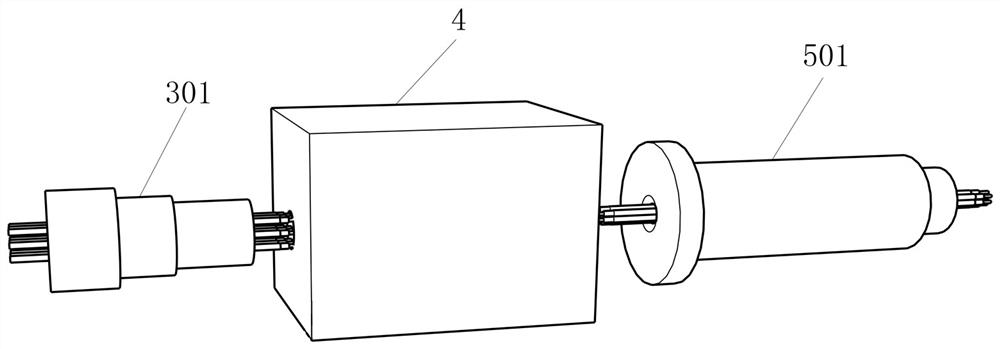

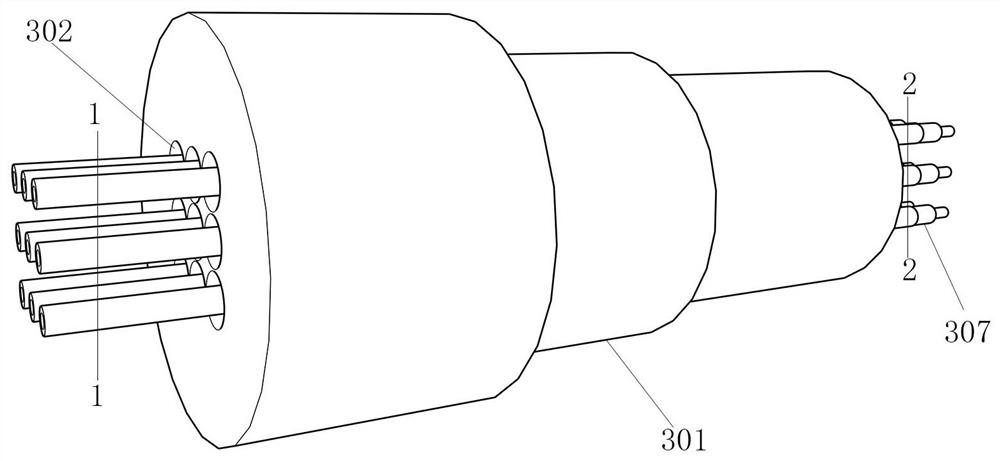

[0054] Such as figure 1 with figure 2 As shown, the pultrusion die includes a yarn cl...

Embodiment 2

[0064] Corresponding to the above pultrusion die used to produce hybrid fiber reinforced polymer rods, this embodiment provides a preparation process for hybrid fiber reinforced polymer rods, including the following steps:

[0065] Step S21, determine the parameters of the target hybrid fiber reinforced polymer rod: HFRP rod diameter D, total fiber volume ratio V f , hybrid fiber volume ratio V L :V H (V L stands for low elongation fiber volume, V H represents the high elongation fiber volume), the cross-sectional area of a single bundle of low strain fibers is S L , the cross-sectional area of the highly strained single-bundle fiber is S H , fiber distribution and other corresponding equipment control parameters.

[0066] The following calculations are required to prepare the target HFRP rod above:

[0067] Total number of bundles required for low strain fibers:

[0068] Total number of bundles required for high strain fibers:

[0069]According to the distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com