Preparation method of MoS2/Ti3C2 MXene composite material for high-performance potassium ion battery

A composite material and potassium ion technology, which is applied in the field of preparation of MoS2/Ti3C2MXene composite materials, can solve the problems of poor cycle stability and reversible capacity fading, and achieve the effect of enhancing capacitance performance, reducing volume expansion and aggregation, and improving storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

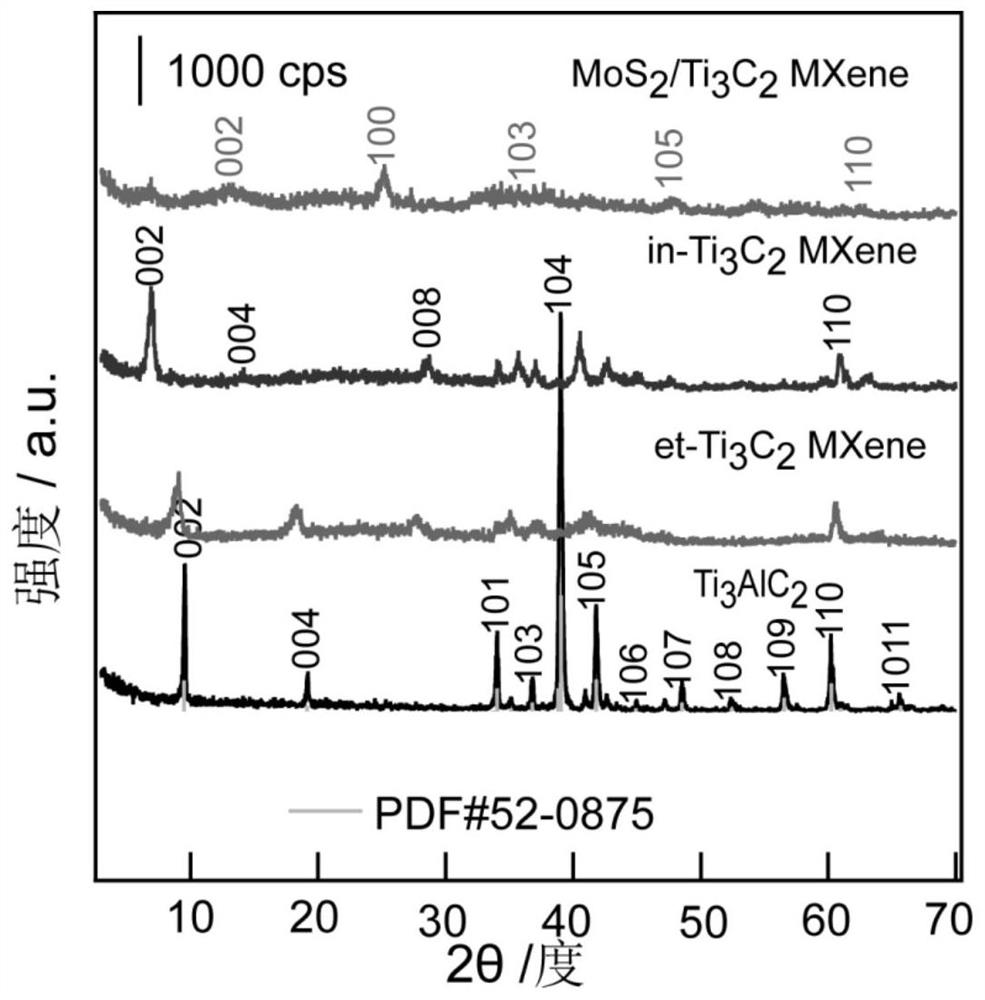

[0049] MOS for high performance potassium ion batteries 2 / Ti 3 C 2 MXENE composites preparation method, including steps as follows:

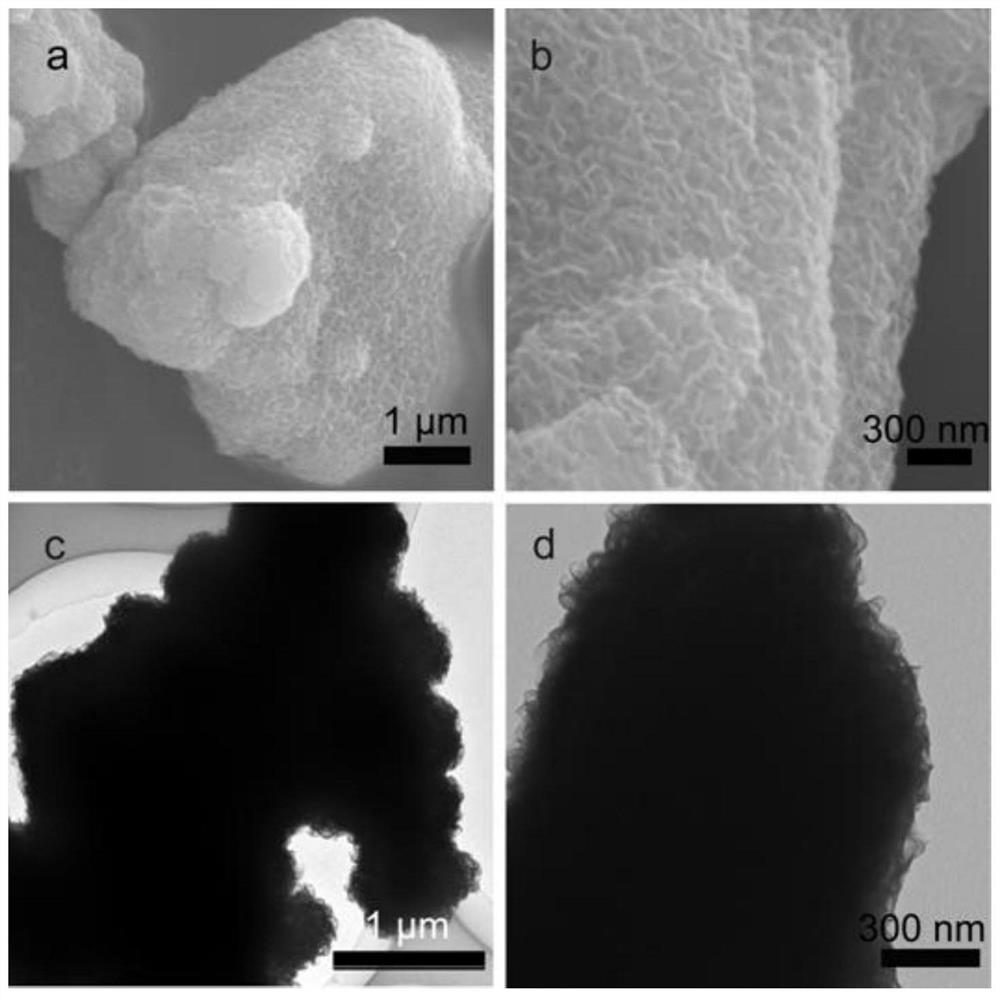

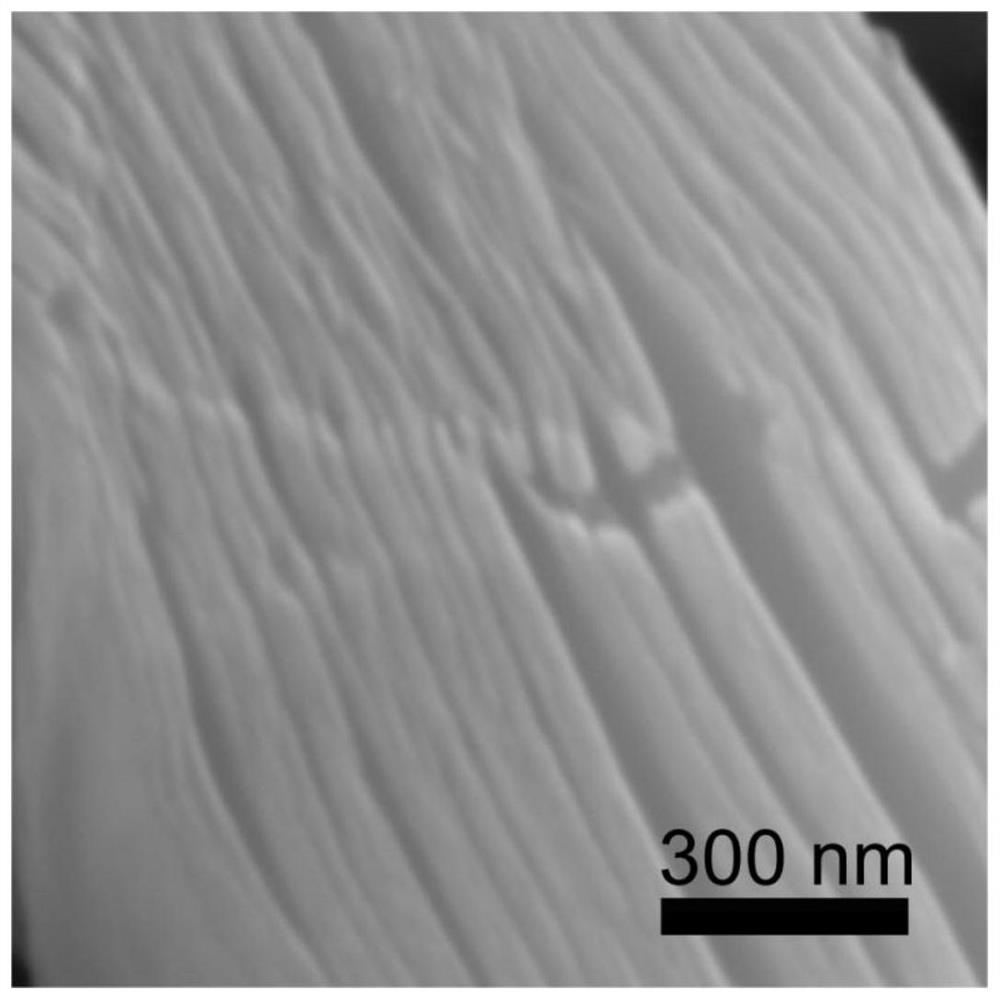

[0050] (1) Preparation ET-Ti 3 C 2 MXENE nanoform

[0051] 1G particle size is less than 38 μm Ti 3 ALC 2 The powder was slowly added to the HF solution of 20 ml of mass fraction of 40 wt%, and used for 0.5 h to avoid overheating exothermic reactions, stirred at 35 ° C for 24 h; with deionized water repeatedly washed the result, centrifugal and decanted until the supernatant The pH of the liquid is 6 to 7, and the resulting precipitate is frozen at -30 ° C for 24 h to give Et-Ti 3 C 2 Mxnen nanoflakes.

[0052] (2) Preparationination in-Ti 3 C 2 MXENE nanoform

[0053] 1G ET-TI 3 C 2 The MXENE nanosin was dispersed in 20 ml of 1.8 mol / l NaOH solution, and the resulting mixture was continuously stirred at room temperature for 6 h; after the reaction was completed, centrifuged, the resulting precipitate was washed 6 times with deionized water, and...

Embodiment 2

[0061] MOS for high performance potassium ion batteries 2 / Ti 3 C 2 MXENE composites preparation method, including steps as follows:

[0062] (1) Preparation ET-Ti 3 C 2 MXENE nanoform

[0063] 1G particle size is less than 38 μm Ti 3 ALC 2 The powder was slowly added to the HF solution of 20 ml of mass fraction of 40 wt%, and used for 0.5 h to avoid overheating exothermic reactions, stirred at 35 ° C for 24 h; with deionized water repeatedly washed the result, centrifugal and decanted until the supernatant The pH of the liquid is 6 to 7, and the resulting precipitate is frozen at -30 ° C for 24 h to give Et-Ti 3 C 2 Mxnen nanoflakes.

[0064] (2) Preparationination in-Ti 3 C 2 MXENE nanoform

[0065] 1G ET-TI 3 C 2 The MXENE nanosin was dispersed in 30 ml of 1.8 mol / lnaH solution, and the resulting mixture was continuously stirred at room temperature for 6 h; after the reaction was completed, the resulting precipitate was washed 6 times with deionized water, and the obtained p...

Embodiment 3

[0069] MOS for high performance potassium ion batteries 2 / Ti 3 C 2 MXENE composites preparation method, including steps as follows:

[0070] (1) Preparation ET-Ti 3 C 2 MXENE nanoform

[0071] 1G particle size is less than 38 μm Ti 3 ALC 2 The powder was slowly added to the HF solution of 20 ml of mass fraction of 40 wt%, and used for 0.5 h to avoid overheating exothermic reactions, stirred at 35 ° C for 24 h; with deionized water repeatedly washed the result, centrifugal and decanted until the supernatant The pH of the liquid is 6 to 7, and the resulting precipitate is frozen at -30 ° C for 24 h to give Et-Ti 3 C 2 Mxnen nanoflakes.

[0072] (2) Preparationination in-Ti 3 C 2 MXENE nanoform

[0073] 1G ET-TI 3 C 2 The MXENE nanosin was dispersed in 20 ml of 1.8 mol / l NaOH solution, and the resulting mixture was continuously stirred at room temperature for 6 h; after the reaction was completed, centrifuged, the resulting precipitate was washed 6 times with deionized water, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com