Method for adding ceramic sintering auxiliary

A technology of sintering aids and ceramics, applied in the field of ceramic materials, can solve problems such as sintering first, difficulty in achieving sintering aids, and agglomeration of aids, and achieve the effects of improving sintering aids, uniform and simultaneous sintering, and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for adding a ceramic sintering aid in this embodiment, the steps are as follows:

[0030] (1) Take 3ml TiCl 4 Dissolve in 30ml ethanol to form TiCl 4 solution;

[0031] (2) Take 100g of alumina powder (W40, with an average particle size of 40μm) and the above TiCl 4 The solution was stirred and mixed, soaked for 15 minutes; then stirred in a fume hood while blowing with hot air until the ethanol was completely dried to obtain a mixed powder;

[0032] (3) Calcining the above mixed powder in a muffle furnace at a temperature of 800°C and keeping it warm for 2 hours to obtain nano-TiO 2 The coating wraps the powder, that is, the sintering aid is nano-TiO 2 The form of coating is wrapped on the surface of alumina powder particles.

[0033] In this embodiment, the nano-TiO wrapped on the surface of the alumina powder particles 2 , whose mass is 0.79% of the mass of alumina powder.

[0034] In this embodiment nano-TiO 2 Add 2% PVA to the coated powder, dry pr...

Embodiment 2

[0036] A method for adding a ceramic sintering aid in this embodiment, the steps are as follows:

[0037] (1) Take 4g ZrCl 4 Dissolve in 50ml ethanol to form ZrCl 4 solution;

[0038] (2) Take 100g of alumina powder (W40, with an average particle size of 40μm) and the above ZrCl 4 The solution was stirred and mixed, soaked for 30 minutes; then stirred in a fume hood while blowing with hot air until the ethanol was completely dried to obtain a mixed powder;

[0039] (3) Calcining the above mixed powder in a muffle furnace at a temperature of 600°C and keeping it warm for 2 hours to obtain nano-ZrO 2 The coating wraps the powder, that is, the sintering aid is nano-ZrO 2 The form of coating is wrapped on the surface of alumina powder particles.

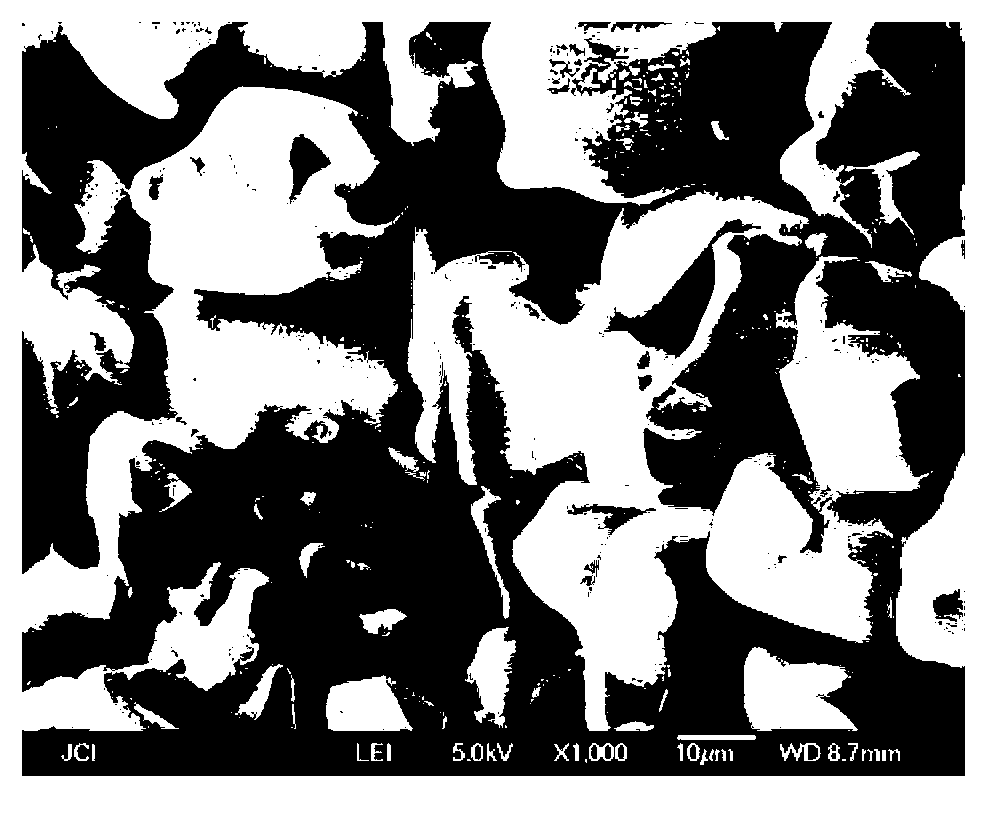

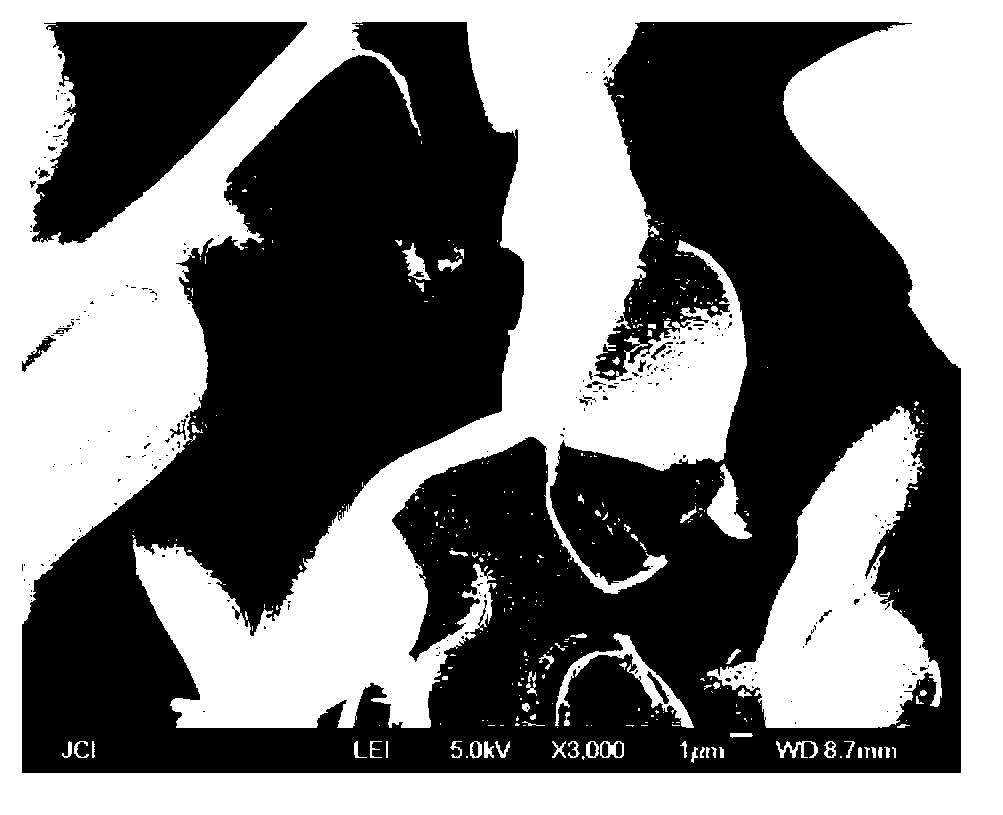

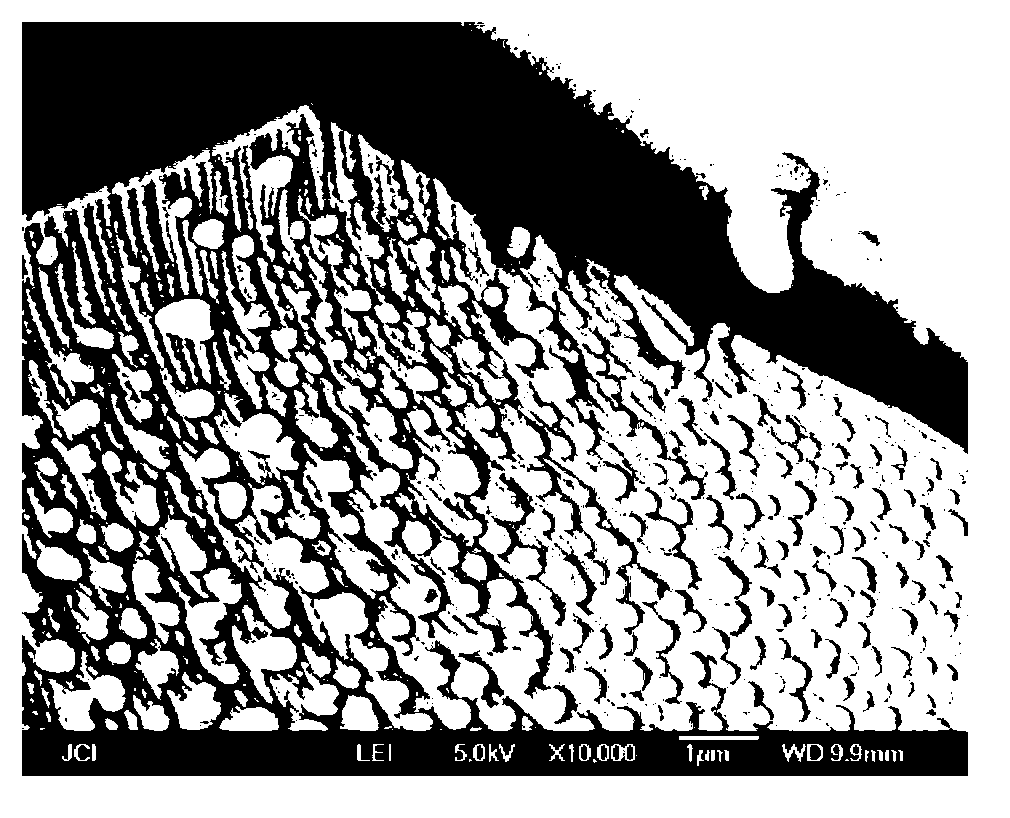

[0040] In this example nano ZrO 2 Add 2% PVA to the coated powder, dry press at 6MPa, and calcinate at 1600°C for 2 hours to obtain porous alumina ceramics. The scanning electron microscope photos of its cross-section are as follows:...

Embodiment 3

[0042] The difference between a method for adding a ceramic sintering aid in this embodiment and the first embodiment is that:

[0043] Step (1) TiCl 4 The dosage is 5ml; the alumina powder in step (2) is ball-milled and mixed with 90g alumina powder (W40, average particle size 40μm) and 10g alumina powder (W1, average particle size 1μm); The time is 60 min; the calcination temperature in step (3) is 850°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com