Method for improving thermal stability of soybean protein by combining preheating and ultrasonic treatment

A technology of soybean protein and thermal stability, applied in the field of vegetable protein processing, can solve the problems of gelation of precipitation system and aggregation of soybean protein.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

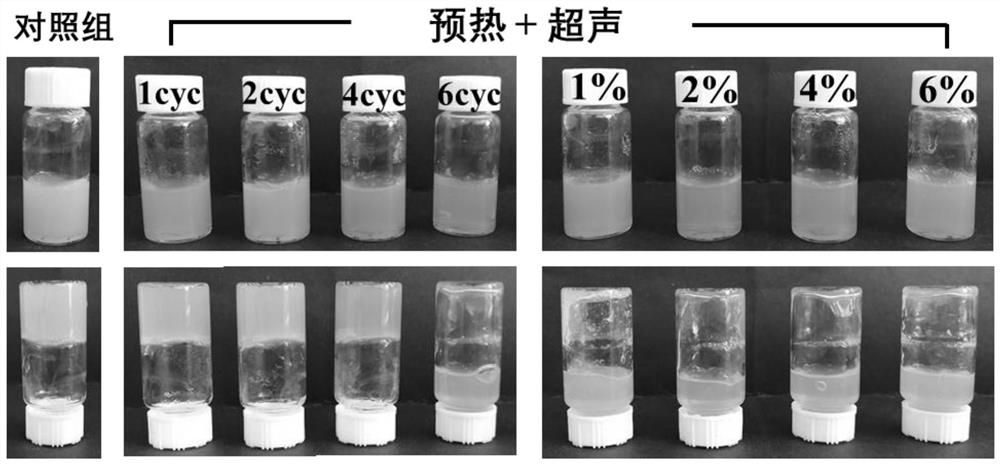

[0040] A thermostable soy protein stability measurement obtained by a combination of preheating and ultrasound: Soy protein without cycle treatment and soy protein treated with 1 cycle, 2 cycles, 4 cycles, 6 cycles were formulated Concentration is 4% suspension, observes at 100 ℃, the stability before and after 30 minutes of preheating; Simultaneously prepare different concentrations of untreated soybean protein (1%, 2%, 4%, 6%), all after 6 Stability before and after 30 min preheating at 100°C was observed after sub-cycle treatment.

[0041] figure 1 In the middle, the lower bottle is the upper bottle after being inverted. If the internal liquid is relatively non-gelled, the liquid will flow down evenly along the wall during the inversion process. If the liquid is gelled, it will easily adhere to the bottom of the bottle and not easy to flow down. Therefore, it can be seen that figure 1 Shown, in the lower circulation (comprising 1,2,4 circulation), the modified soybean pro...

Embodiment 2

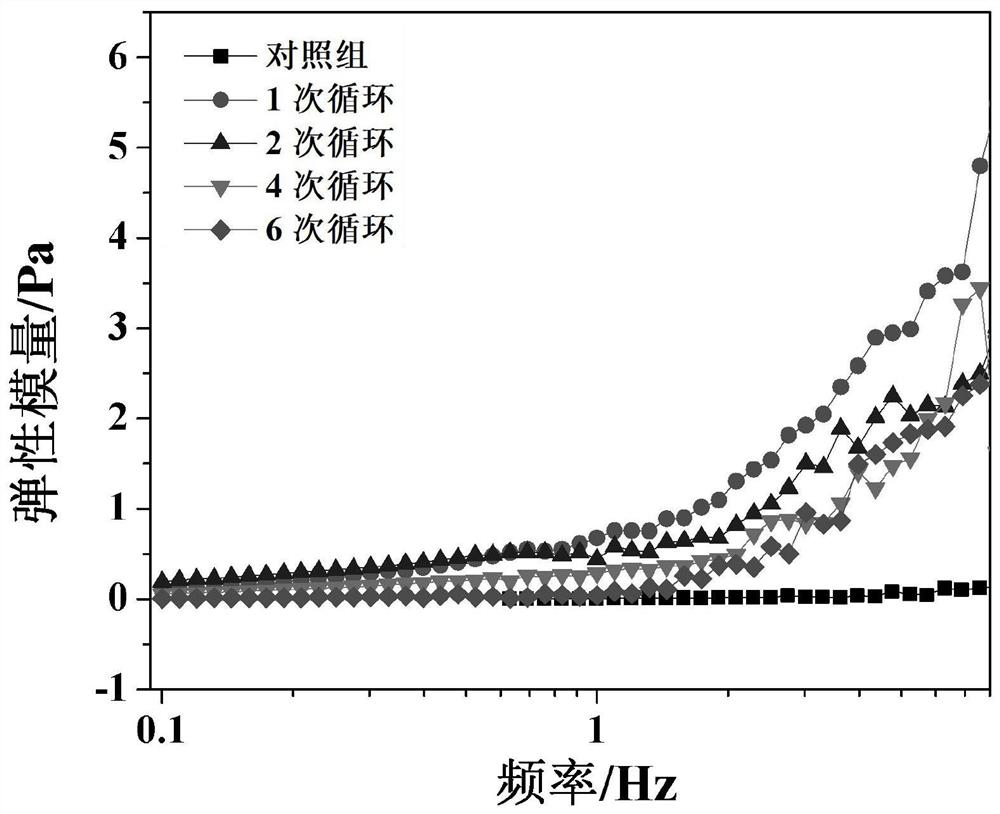

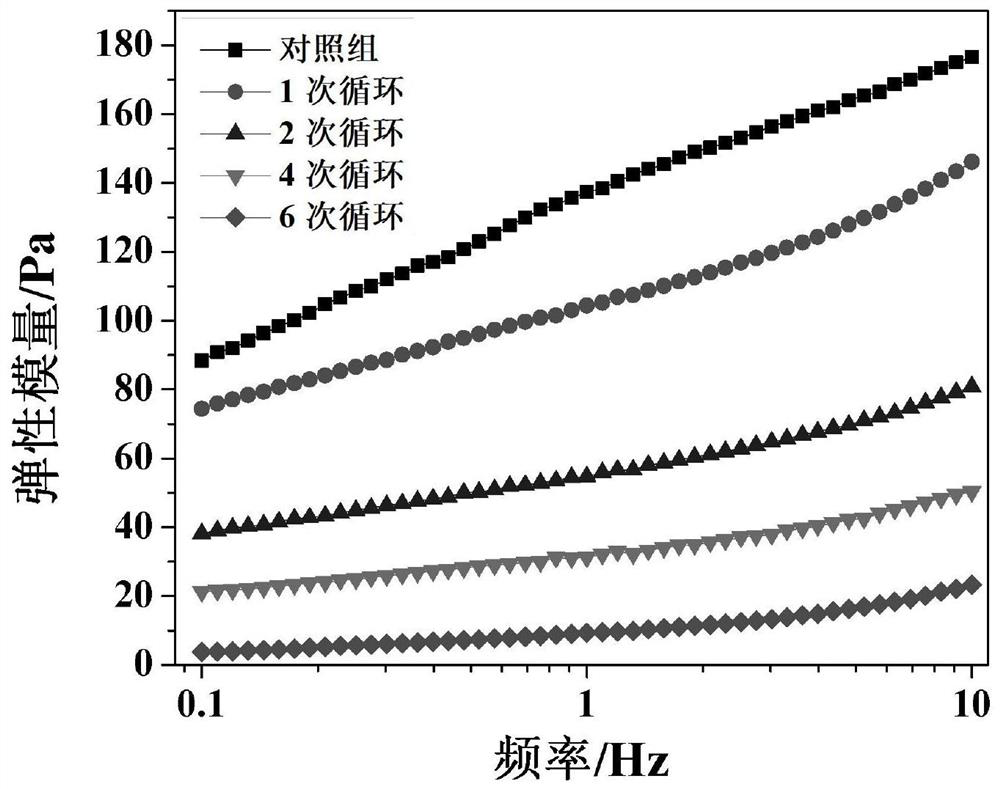

[0043] A measurement of thermally stable soybean protein storage modulus and viscosity obtained by preheating and ultrasonic combination: prepare a soybean protein suspension with a concentration of 10%, and go through 1 cycle, 2 cycles, 4 cycles, and 6 cycles respectively. The storage modulus and viscosity values were measured before and after 30 minutes of preheating at 100°C using a rheometer after the secondary cycle treatment. like figure 2 , for the modified soybean protein suspension treated with combined preheating and ultrasonic treatment with different cycles, the storage modulus value decreased slightly with the increase of the treatment cycle before reheating treatment. like image 3 , the storage modulus value of the control sample after heat treatment was the highest. like Figure 4 , 10% modified soybean protein suspension in 0.1 ~ 10s -1 Viscosity at shear rate. In suspensions before reheating, increasing the cycle of preheating and ultrasonic treatment ...

Embodiment 3

[0045] Calculation of the fluidity index of heat-stable soybean protein obtained by combining preheating and ultrasound: prepare soybean protein suspension with a concentration of 10%, and process it through 1 cycle, 2 cycles, 4 cycles, and 6 cycles respectively Calculate the flow performance index at 100°C before and after 30 minutes of preheating; prepare soybean protein suspensions with a concentration of 1%, 2%, 4%, and 6%, and calculate them at 100 after 6 preheating ultrasonic cycles. °C, flow performance index before and after 30 min warm-up. As in Table 1:

[0046]Table 1 After (100°C, 30 minutes) reheating treatment, the flowability index of 10% concentration modified soybean protein

[0047]

[0048]

[0049] When the value of n is close to 1, the suspension can be classified as Newtonian fluid, and the suspension with higher flow performance index has better fluidity. The n value of soybean protein in the control group after heat treatment was the lowest, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com