Integrated preparation process of big-tow carbon fiber spreading and curing

A tow carbon fiber and carbon fiber technology, which is applied in the field of integrated preparation of large tow carbon fiber widening and curing, can solve the problems of difficulty in widening large tow carbon fibers, high yarn utilization rate, and poor widening effect, etc. The effect of solving carbon fiber damage, high yarn utilization rate, and improving the effect of widening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

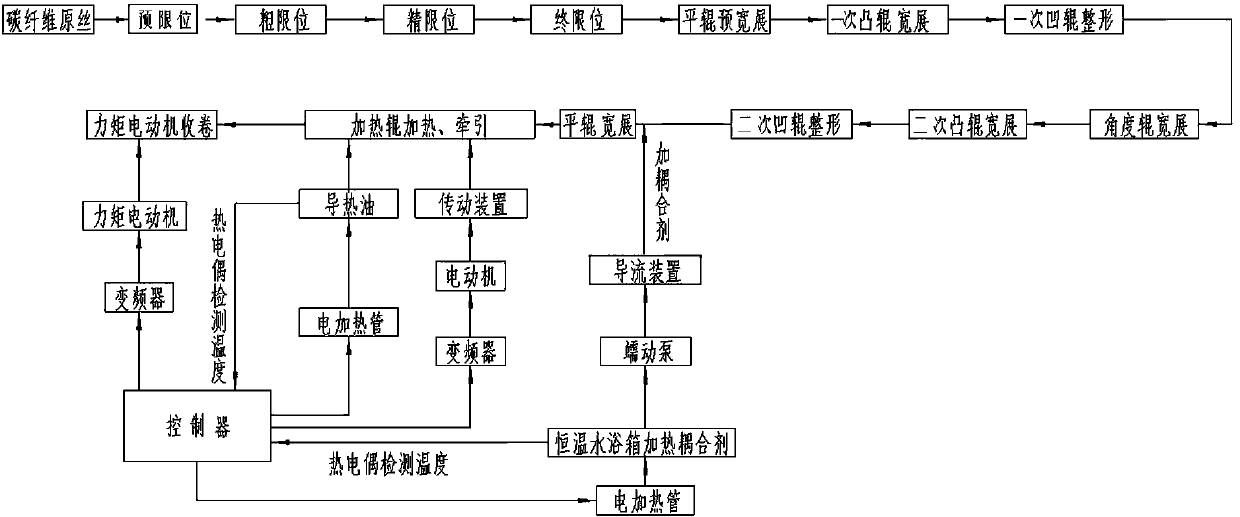

[0047] The integrated preparation process of large-tow carbon fiber spreading and curing includes the following steps:

[0048] (1) Precisely limit the carbon fiber precursor to ensure the neutrality of the carbon fiber precursor when it is stretched;

[0049] (2) After precise positioning, the carbon fiber precursors are spread, mainly through the combination of multiple special-shaped spreads and angle spreads to realize the spread of large tow carbon fibers. The specific process is: sequentially pre-spread by flat rollers, Convex roll widening, primary concave roll shaping, angle roll widening, secondary convex roll widening, secondary concave roll shaping, and flat roll widening complete the widening of carbon fiber precursors;

[0050] (3) Add coupling agent to the carbon fiber precursor to infiltrate before the carbon fiber precursor is widened;

[0051] (4) heating and solidifying the infiltrated carbon fiber precursor by traction through heating rollers;

[0052] (5) R...

Embodiment 2

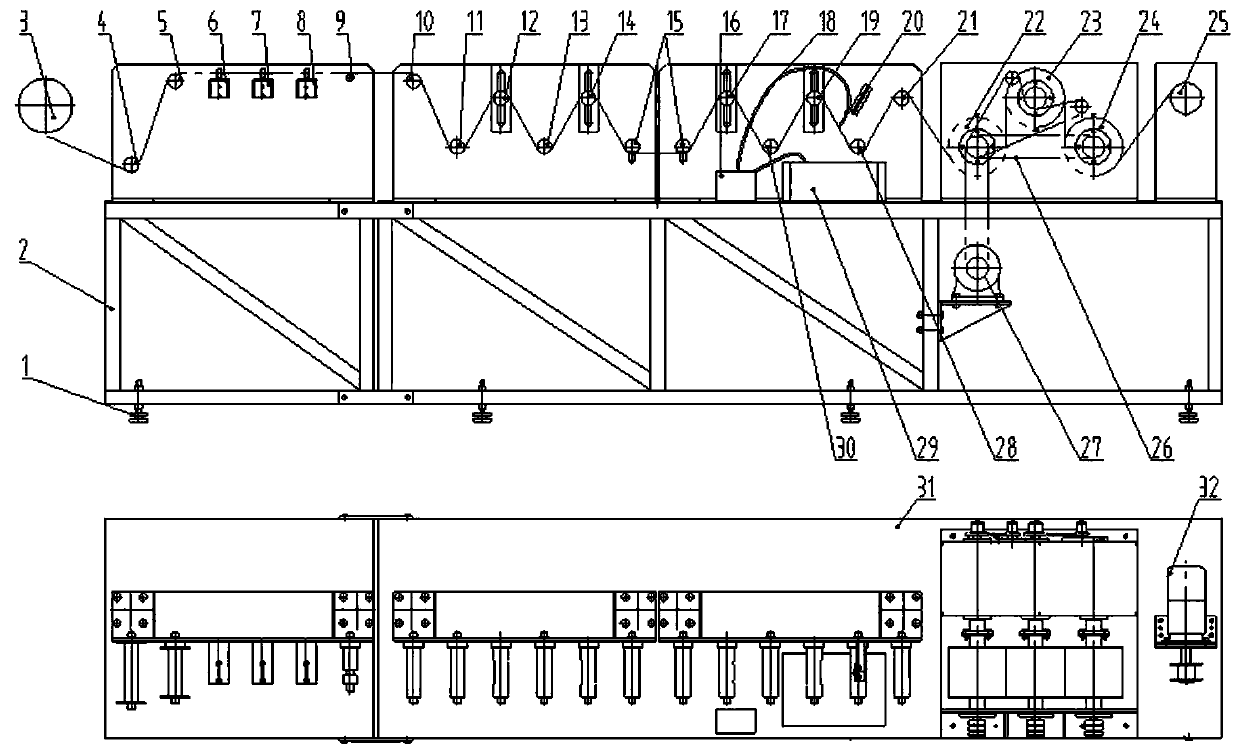

[0058] refer to figure 2 , large tow carbon fiber widening and curing integrated preparation equipment, including: frame, carbon fiber guiding system, carbon fiber widening system, coupling agent adding system, traction heating curing system and receiving system, the frame is equipped with carbon fiber Guiding system, carbon fiber spreading system, couplant adding system, traction heating curing system and material receiving system, this preparation equipment is an equipment integrating spreading, infiltration and heating curing.

[0059] Wherein, the frame includes a short bed 2 and a long bed 31, and the short bed 2 and the long bed 31 are provided with feet 1 (the feet of the long bed 31 are not shown in the figure).

[0060] The carbon fiber guiding system precisely limits the carbon fiber precursor, specifically including a pre-limiting roller 4, a rough limiting roller 5, a first fine limiting wheel 6, a second fine limiting wheel 7, and a third fine limiting wheel 8. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com