Charging technology capable of improving yield of CO2 supercritical extraction

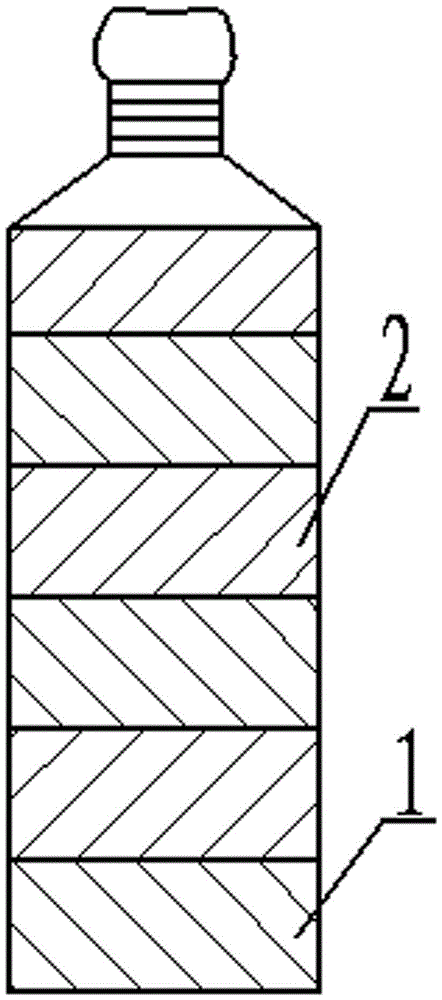

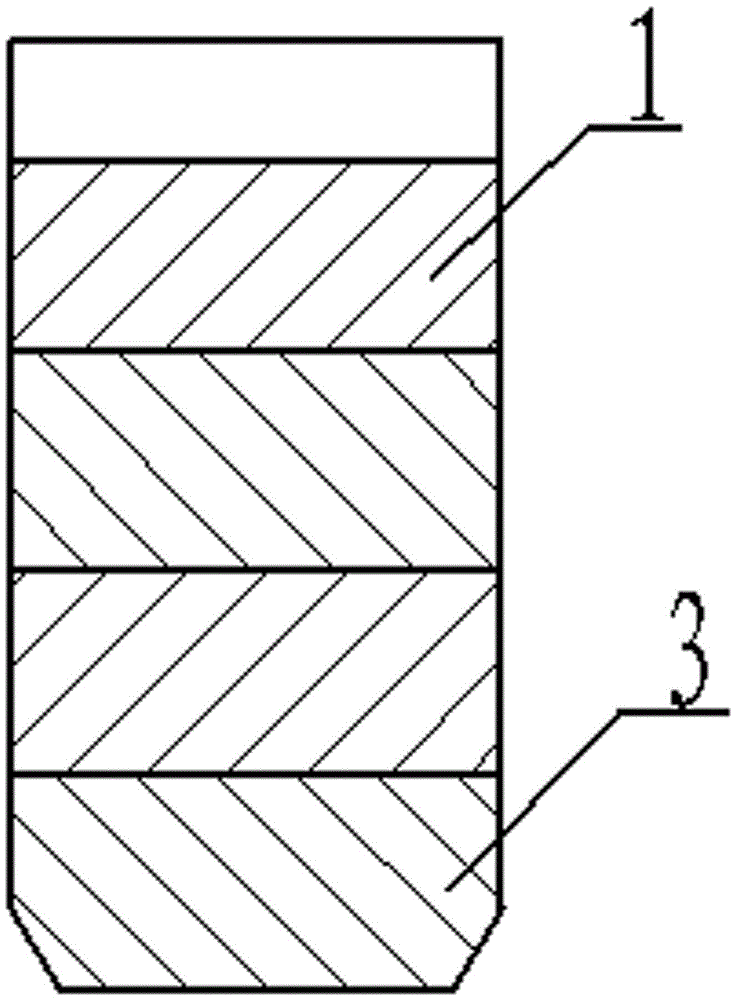

A high-yield, supercritical technology, applied in solvent extraction, solid solvent extraction, chemical instruments and methods, etc., can solve the problems of unstable extraction yield, large waste of raw materials, poor permeability, etc., to solve the problem of poor material permeability , reduced processing costs, and stable output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1, CO 2 Comparison of experimental effects of flavor components in supercritical extraction of distiller's grains:

[0032] 1. Materials and test equipment required for the test

[0033] Liquor waste: provided by Shanxi Fenjiu Group Co., Ltd. (the water content in the trough is about 60%, the lower the water content in the trough, the better);

[0034] High-purity carbon dioxide: purity ≥ 99.99%, food grade;

[0035] Test equipment: supercritical extraction equipment produced by Sichuan Deyang Sichuang Technology Co., Ltd.

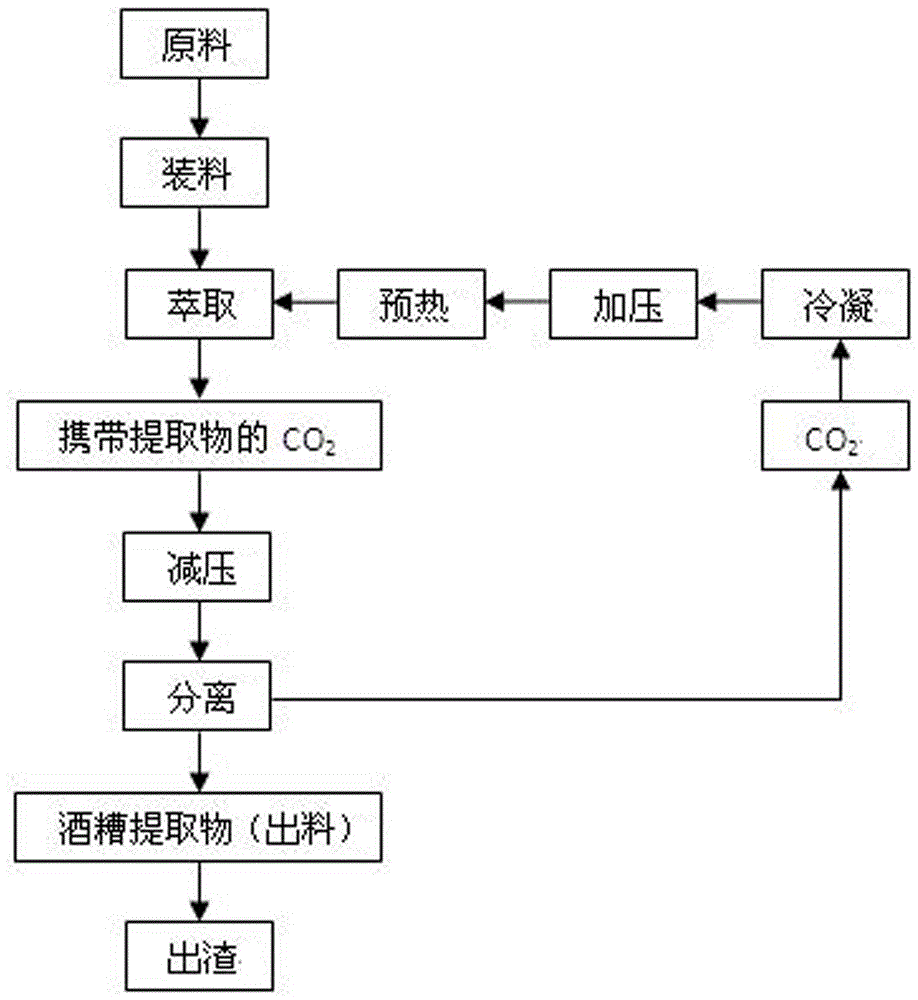

[0036] After loading the raw materials (using the traditional method and the method of the present invention respectively), the CO 2 Inject into the extraction kettle, adjust the pressure and temperature to make it carry the extract in a supercritical state, enter the separation kettle, and then analyze the distiller's grain extract (flavor substance) through decompression.

[0037] 3. Extraction implementation process

[0038] After ...

Embodiment 2

[0047] Example 2, CO 2 Comparison of experimental results of supercritical extraction of seabuckthorn seed oil:

[0048] 1. Materials and test equipment required for the test

[0049] Seabuckthorn seeds: pressed high-quality seabuckthorn seeds, moisture content 10%~13%;

[0050] High-purity carbon dioxide: purity ≥ 99.99%, food grade;

[0051] Test equipment: supercritical extraction equipment produced by Sichuan Deyang Sichuang Technology Co., Ltd.

[0052] 2. Example 1 of extraction process and extraction implementation process.

[0053] After the normal extraction process of the system is completed, the discharge valves at the bottom of the separators I and II are respectively opened to release all the extracted seabuckthorn seed oil.

[0054] Table 2 is traditional method and the inventive method CO 2 Parameters and Yield Data Comparison of Supercritical Extraction of Seabuckthorn Seed Oil

[0055] Table 2

[0056]

[0057] CO through the above two different feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com