Plate heat exchanger and heat exchanger plant

A technology of plate heat exchangers and heat exchangers, applied in heat exchange equipment, lighting and heating equipment, heat exchange equipment safety devices, etc., can solve the problems of serious quantity and performance reduction of plate heat exchangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

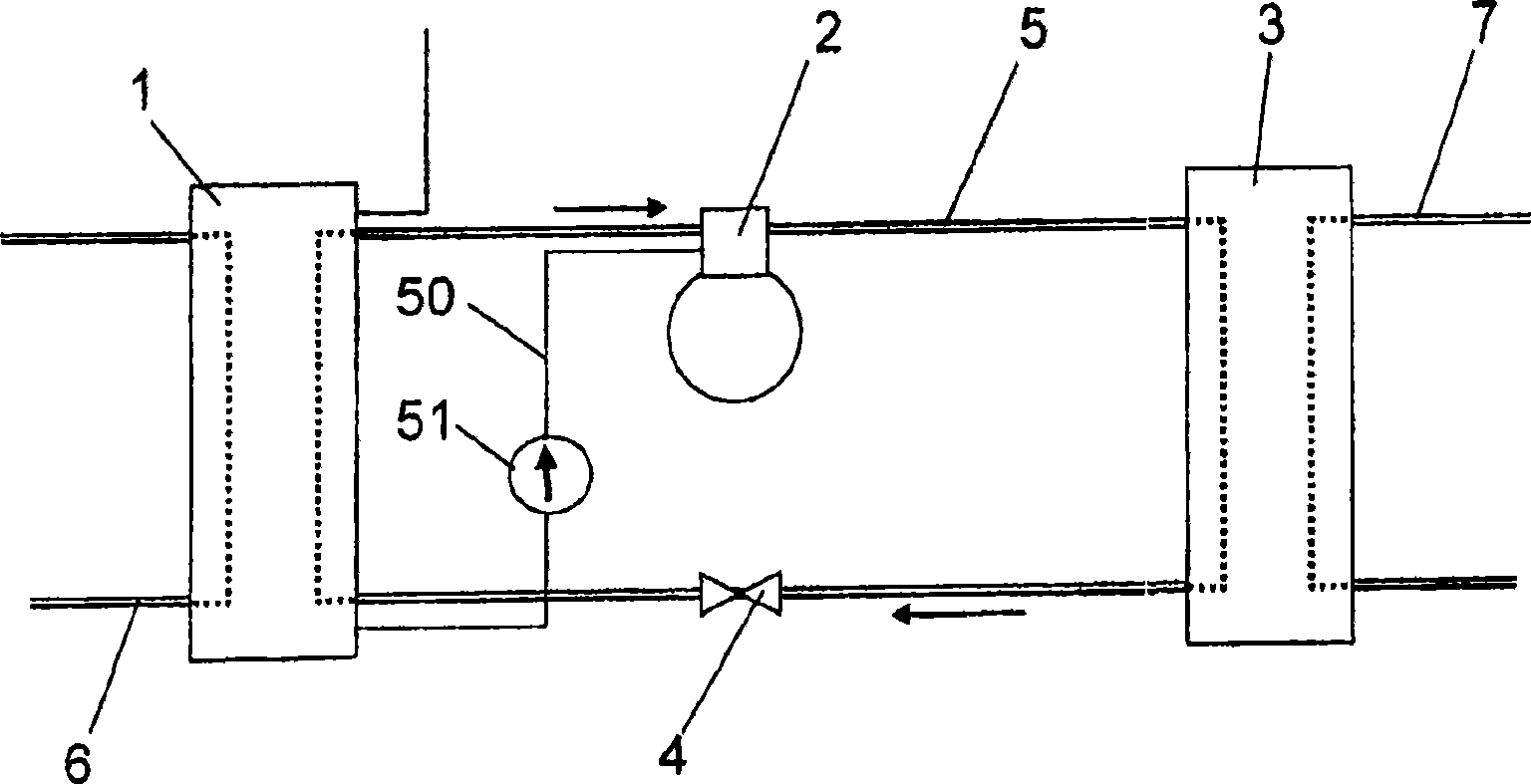

[0031] figure 1 A heat exchanger apparatus comprising an evaporator 1, a compressor 2, a condenser 3 and an expansion element 4 is disclosed. The evaporator 1 , the compressor 2 , the condenser 3 and the expansion element 4 are connected to each other by a cooling medium pipe 5 and form a closed cooling medium circuit through which the first medium circulates. In the disclosed embodiments, the first media all include or consist of ammonium as a major component. The present invention is also applicable to other cooling media than ammonium, such as different types of Freon. A second medium for heating the cooling medium is also supplied to the evaporator 1 via the external circuit 6 . The condenser 3 is also connected to an external circuit 7 for supplying a third medium of cooling cooling medium.

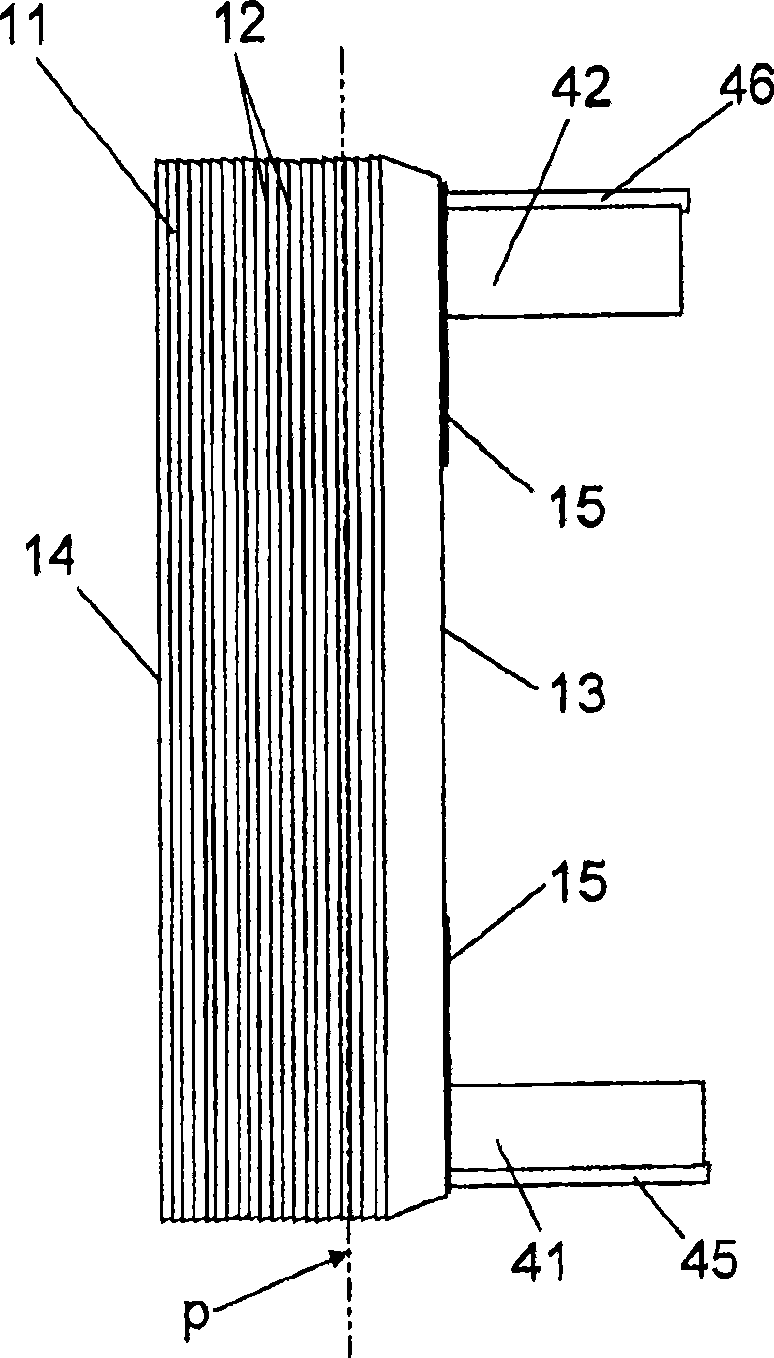

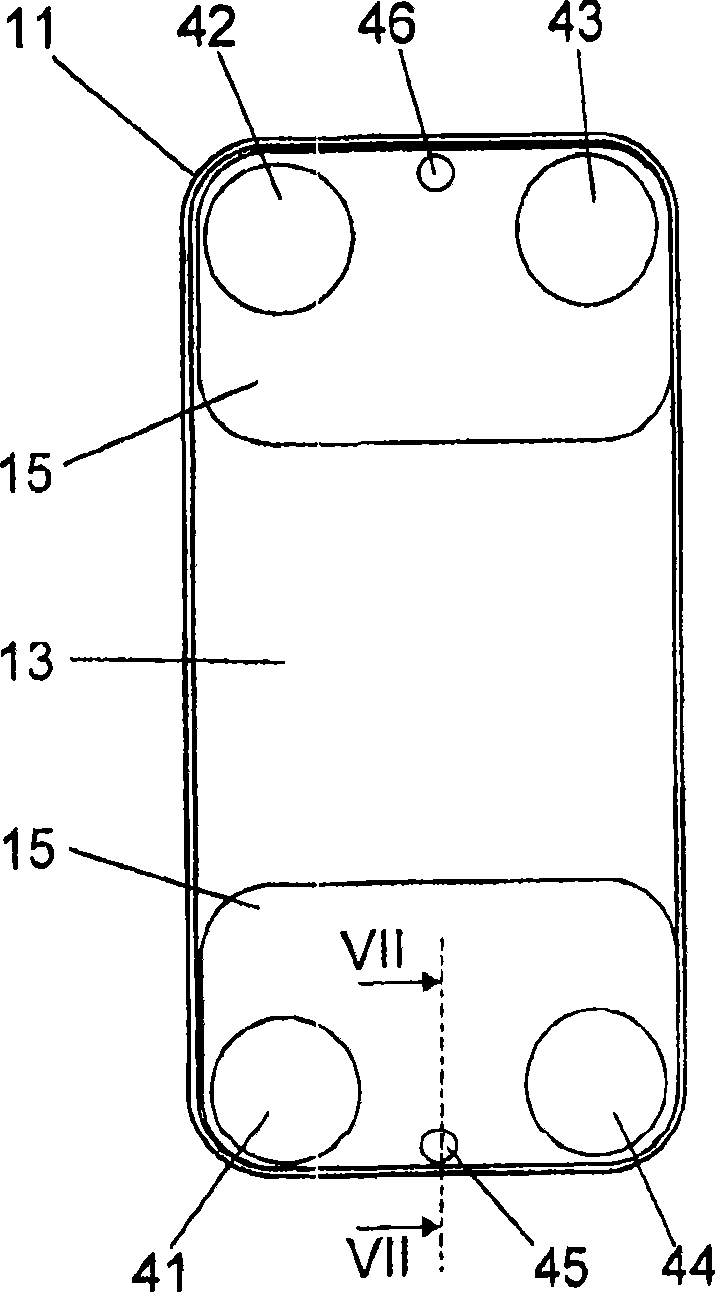

[0032] Next, in one embodiment, the plate heat exchanger will be explained further, where the plate heat exchanger is used as an evaporator. It should be noted, however, that a pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com