Method for preparation of graphene/carbon aerogel composite material

A composite material, carbon aerogel technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems affecting the combination of carbon aerogel and graphene, and achieve the effect of promoting application development, improving conductivity, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

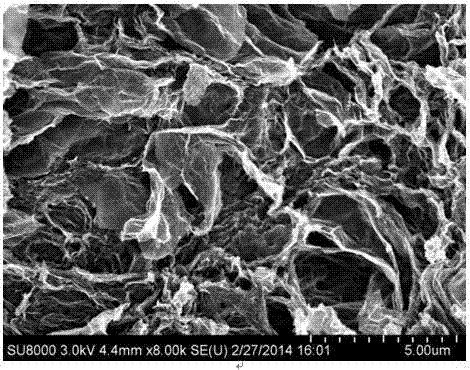

[0032] Take graphene oxide, put it into deionized water, and ultrasonically disperse it to obtain a graphene oxide dispersion with a concentration of 3mg / ml, put it into a hydrothermal reactor, seal it, and treat it at 180°C for 24 hours to obtain a reduced graphene hydrogel glue, freeze-dried to obtain reduced graphene foams.

[0033] Get resorcinol and formaldehyde, the molar ratio is 0.5, add in deionized water and mix evenly, control the solution concentration to be 40%, add catalyst sodium carbonate again, the molar ratio of catalyst and resorcinol is 1 / 1000, stir evenly, Obtain the carbon airgel liquid precursor.

[0034] Then put the graphene foam into a polytetrafluoro container with a sealed cover. The inner cavity of the container is similar in size to the graphene foam. Slowly add the carbon airgel liquid precursor through the needle until the liquid precursor is covered by the graphene foam. On the upper surface, the graphene foam is completely immersed in the liq...

Embodiment 2

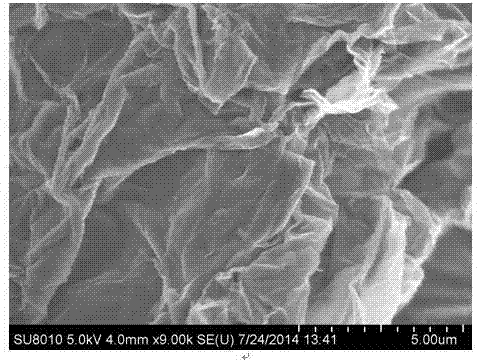

[0036] Take graphene oxide, prepare it into a 3mg / ml solution, and disperse it ultrasonically for 7 minutes to obtain a graphene oxide dispersion, add ethylenediamine at a ratio of 12500:1 to obtain a mixed solution, drop the solution into a plastic container, and seal it for 95 °C, treated for 24 hours, the reduced graphene oxide group grows into a foam, and then the wet foam is freeze-dried to obtain a reduced graphene foam.

[0037] Get resorcinol and formaldehyde, the molar ratio is 0.5, add in deionized water and mix evenly, control the solution concentration to be 40%, add catalyst sodium carbonate again, the molar ratio of catalyst and resorcinol is 1 / 1000, stir evenly, Obtain the carbon airgel liquid precursor.

[0038] Then the graphene foam is immersed in the gel liquid precursor, vacuumed to 0.1 Pa, and after 5 minutes, impregnated and compounded. Then seal the impregnated composite graphene foam, place it in an oven, and keep the temperature at 50°C for 1 day to o...

Embodiment 3

[0039] Embodiment 3 evaluates the optimization to material by electrochemical performance test:

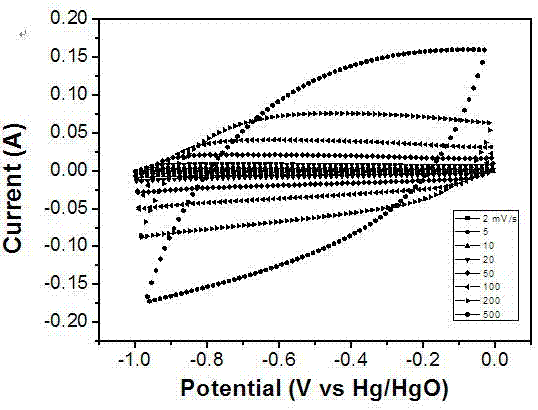

[0040]The material prepared in Example 1 of the present invention is applied to a supercapacitor. Take 0.85 g of this product, add 0.15 g of polytetrafluoroethylene, add ethanol dropwise, mix evenly, roll it into thin slices on stainless steel, and punch it into a diameter of about 10 mm with steel. Circular flakes with a weight of 2-10 mg are used as supercapacitor electrode sheets, and the electrode sheet is pressed on the nickel foam current collector with foam nickel, 6 mol L -1 Potassium hydroxide (KOH) aqueous solution is used as electrolyte, cyclic voltammetry scan, scan window -1~0 V (vs. Hg / HgO), the curve is an approximately symmetrical rectangle, as shown in the attached image 3 shown. At a scan rate of 2 mV s -1 , calculated according to the integral area of the curve, the capacity of the supercapacitor is 144F·g -1 .

[0041] Compared with the carbon airgel ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com