Preparation method of Pt-Ru alloy catalyst with high catalytic activity

A high catalytic activity, alloy catalyst technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the limitation of single metal Pt application, expensive, poisoning, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

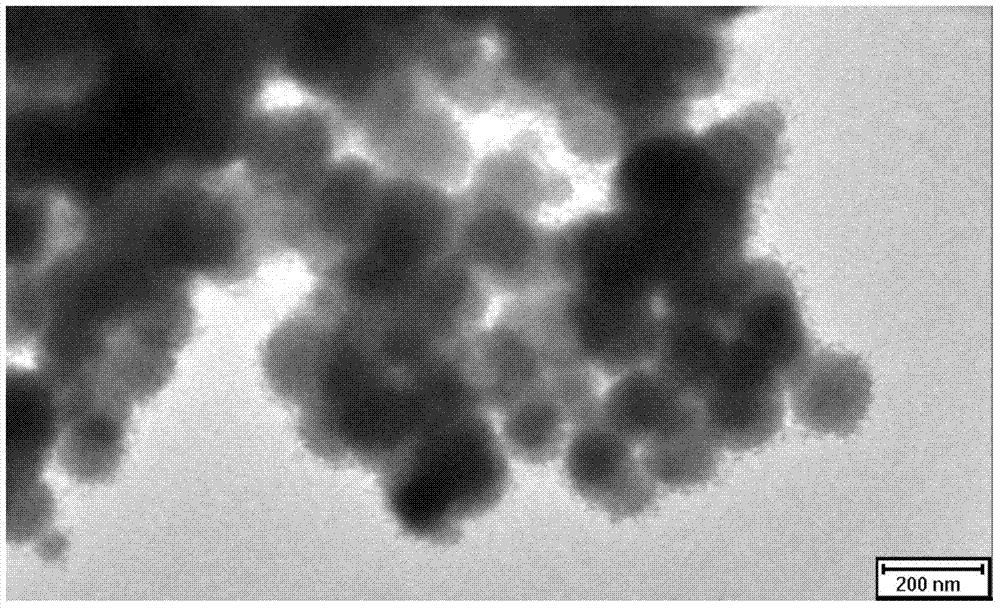

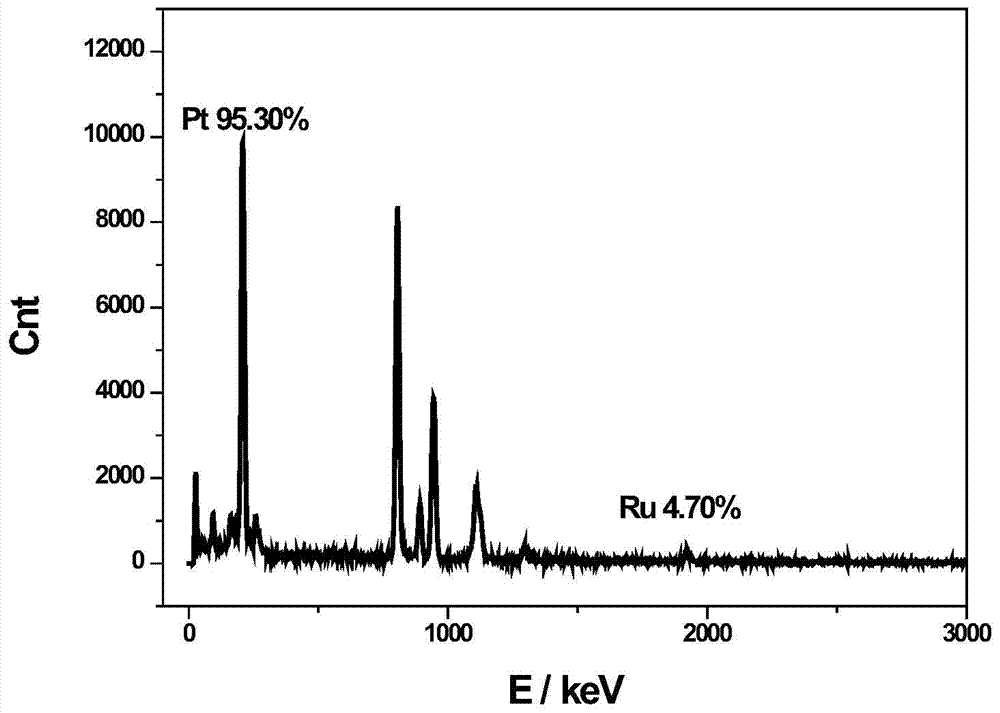

Image

Examples

Embodiment 1

[0025] (1). Take a certain quality of chloroplatinic acid (H 2 PtCl 6 ·6H 2 O), hydrated ruthenium trichloride (RuCl 3 ·nH 2 O, the mass fraction of Ru is 40%), amphiphilic block copolymer P123 (EO 20 PO 70 EO 20 ), deionized water, absolute ethanol:

[0026]

[0027] (2). First add ethanol to the amphiphilic block copolymer P123 (EO 20 PO 70 EO 20 ), then add deionized water, and mix thoroughly at 25°C. After P123 is completely dissolved and fully mixed, the mixed solution is added to chloroplatinic acid (H 2 PtCl 6 ·6H 2 O), hydrated ruthenium trichloride (RuCl 3 ·nH 2 (0) in the mixture, leave standstill after mixing evenly, treat that ethanol is all volatilized;

[0028] (3). Lyotropic liquid crystals are formed after ethanol is completely volatilized, and 0.1mol / L ascorbic acid aqueous solution is prepared. This solution will be used as a reducing agent for the reaction. Take 5mL reducing agent and add it to the lyotropic liquid crystal, and reduce it in ...

Embodiment 2

[0035] The preparation method of the Pt-Ru alloy catalyst of high catalytic activity, step is with embodiment 1, and difference is that the hydrated ruthenium trichloride (RuCl 3 ·nH 2 O) The mass is 0.016g.

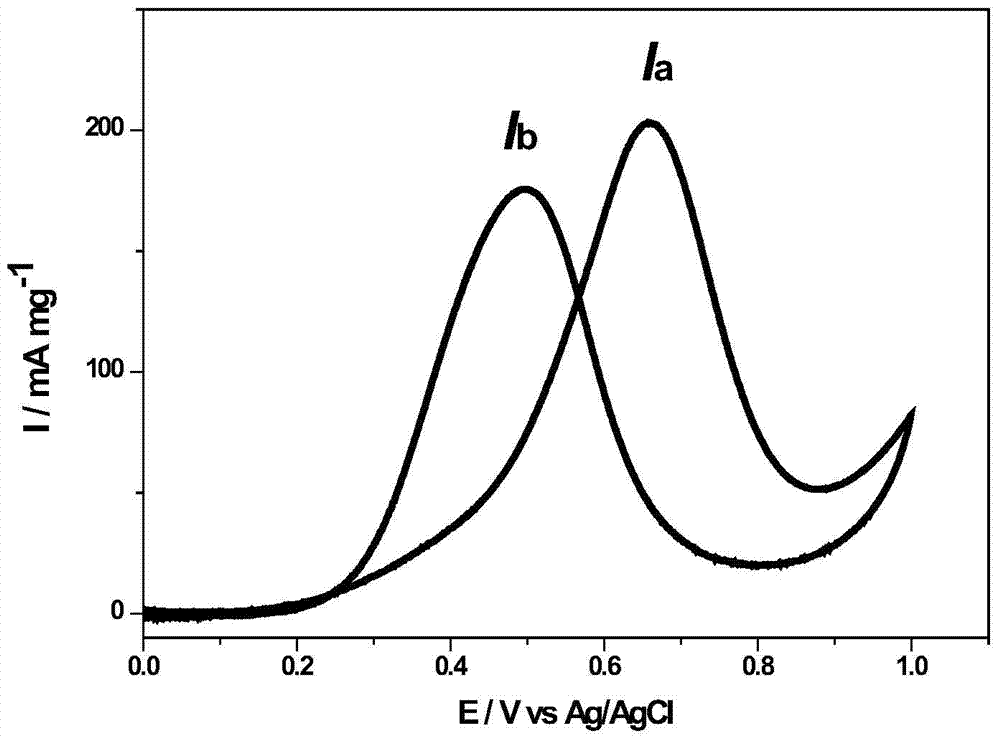

[0036] image 3 Shown is the Pt-Ru alloy catalyst of the high catalytic activity prepared by example 2 at 0.5mol / LH 2 SO 4 +1mol / L CH 3 The cyclic voltammetry curve in the solution of OH, it can be seen from the figure that the peak current density at 0.67 V is 202mA / mg, compared with the peak current density (about 100mA / mg) of commercial platinum black increase; and, the peak current density I of the positive potential scan a Peak current density I b The ratio is 1.15, indicating that the as-prepared Pt catalyst is comparable to commercial platinum black (I a / I b =0.85-0.95) has higher anti-toxin performance.

[0037] Figure 4 Shown is the Pt-Ru alloy catalyst of the high catalytic activity prepared by example 2 at 0.5mol / LH 2 SO 4 The cyclic voltammetry ...

Embodiment 3

[0039] The preparation method of the Pt-Ru alloy catalyst of high catalytic activity, step is with embodiment 1, and difference is that the hydrated ruthenium trichloride (RuCl 3 ·nH 2 O) Mass is 0.024g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peak current density | aaaaa | aaaaa |

| Peak current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com