Method for preparing nano-dendritic platinum catalyst

A nanostructure, platinum catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, nanotechnology, etc., can solve the application limitations of platinum dendritic nanostructures, complex reaction processes, and long reaction times. Simple method, high electrocatalytic activity, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) First, weigh 1.0g of H with an electronic balance 2 PtCl 6 ·6H 2 O, dissolved in 60 mL deionized water to make 60 mL 0.06 mM H 2 PtCl 6 solution; then add 3.0 g of PVP to the Wang solution, stir well and then add 3ml of isopropanol to form a well-mixed solution.

[0024] (2) Put the uniformly mixed solution into a plastic bag, irradiate with a dose of 140KGy, and irradiate at a current of 7mA for 10 minutes to obtain a black solution.

[0025] (3) Transfer the obtained product to a centrifuge tube, then centrifuge at high speed for 30min (16000rpm), discard the upper layer, wash the precipitate with ethanol and water repeatedly, and centrifuge several times until no suspended matter appears in the upper layer.

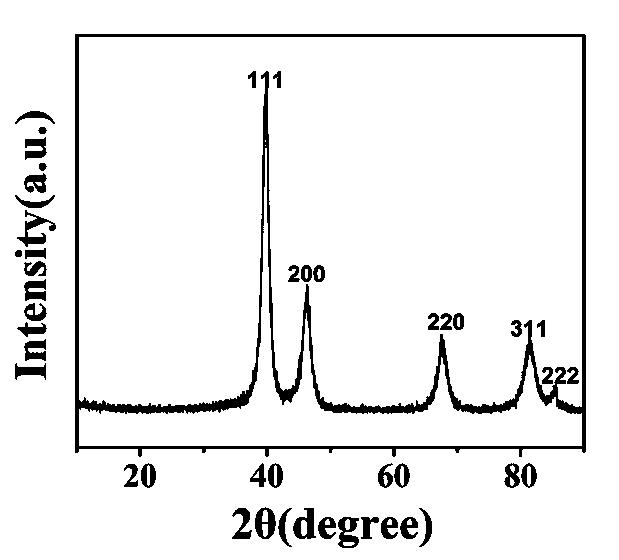

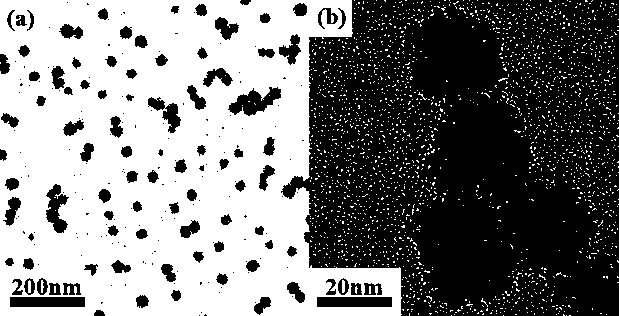

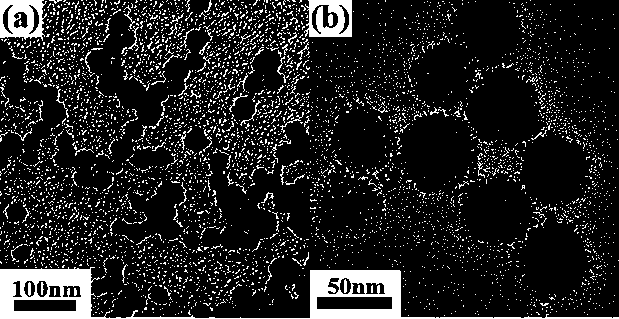

[0026] (4) Dry the precipitate in a vacuum drying oven at a temperature of 60° C. for 10 hours to obtain a black platinum dendritic nanostructure.

[0027] (5) Use a clean glassy carbon electrode as the working electrode, a calomel electrode as the ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com