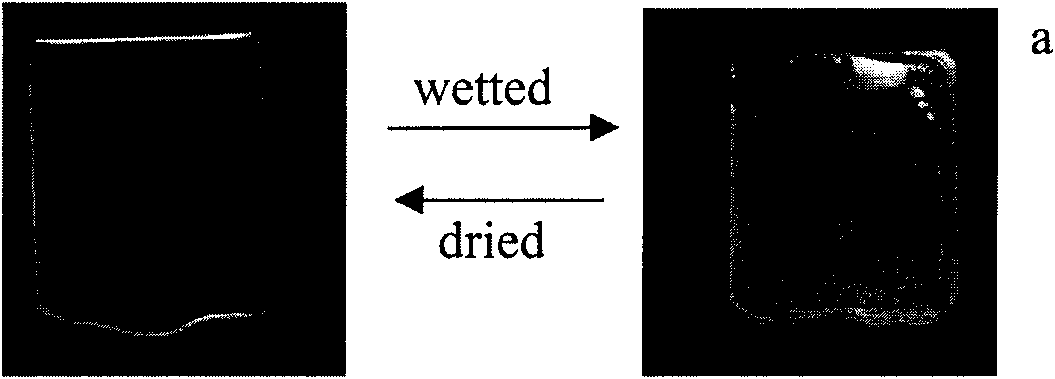

Lyotropic color response transparent film material and preparation method thereof

A transparent film and color technology, applied in the direction of coating, etc., can solve the problems of difficult large-area preparation of film materials, poor material flexibility, difficult to form, etc., and achieve the effect of fast lyotropic color response, excellent mechanical properties, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

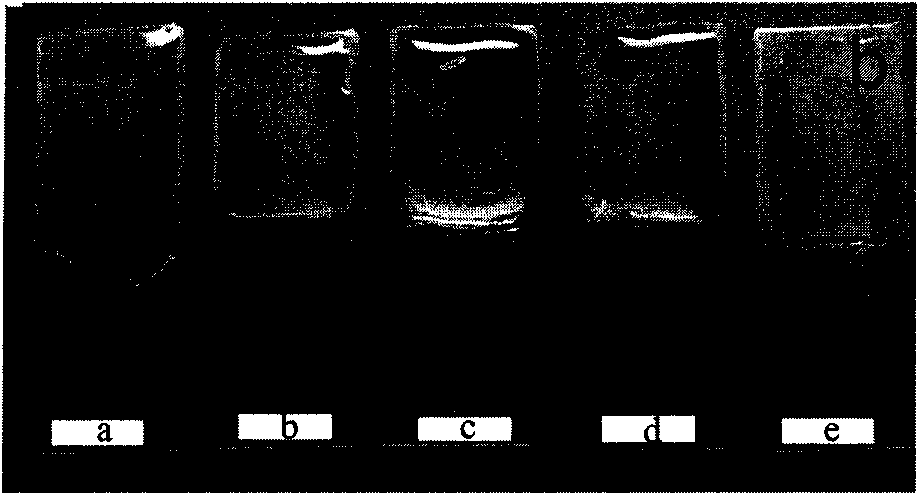

Embodiment 1

[0045] Mix ethylenic monomers such as methyl methacrylate: 2-hydroxyethyl acrylate: vinyl acetate: methylvinyldimethoxysilane in a ratio of 30:20:20:30, and prepare monodisperse by emulsion polymerization polymer latex.

Embodiment 2

[0047] Mix ethylenic monomers such as butyl acrylate: methacrylic acid: styrene: methacrylamide in a ratio of 60:10:20:10, and prepare monodisperse polymer latex by dispersion polymerization.

Embodiment 3

[0049] Mix ethylenic monomers such as methyl styrene:perfluoropropyl vinyl ether, acrylic acid, and butyl acrylate in a ratio of 40:10:40:10, and prepare polymer latex by suspension polymerization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com