Photocurable adhesive agent, polarizing plate using the photocurable adhesive agent, method for production of the polarizing plate, optical member, and liquid crystal display device

A light-curable and adhesive technology, applied in the direction of polarizing elements, nonlinear optics, chemical instruments and methods, etc., can solve problems such as insufficient adhesive strength, thermal aging of adhesives, poor appearance, etc., and achieve storage stability Excellent, discoloration-inhibiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1,2

[0178] [Example 1, 2, Comparative Example 1, 2]

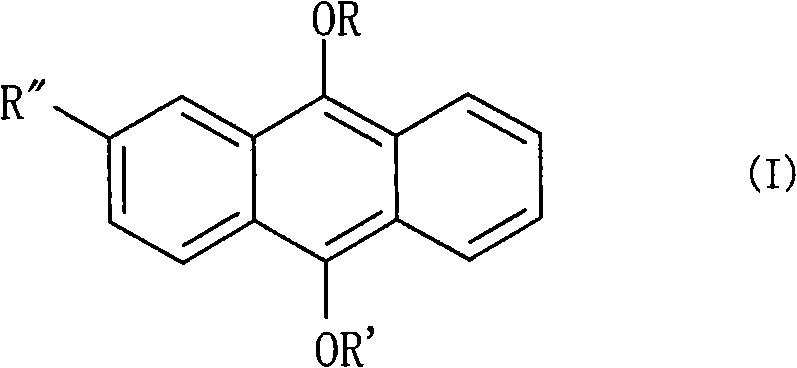

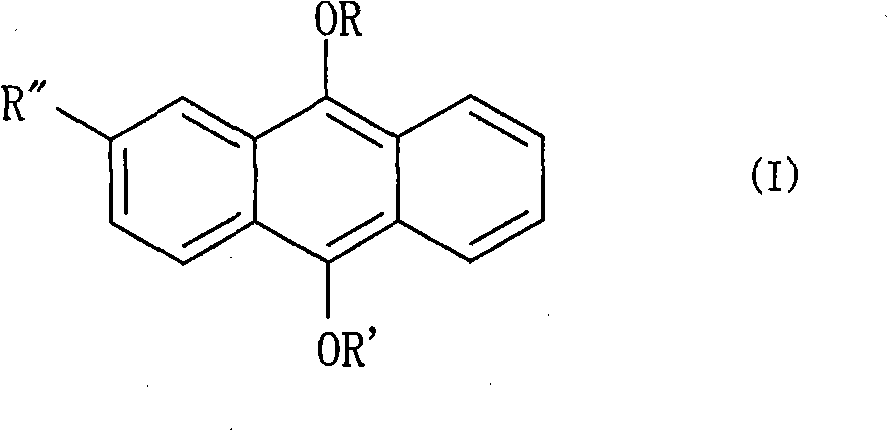

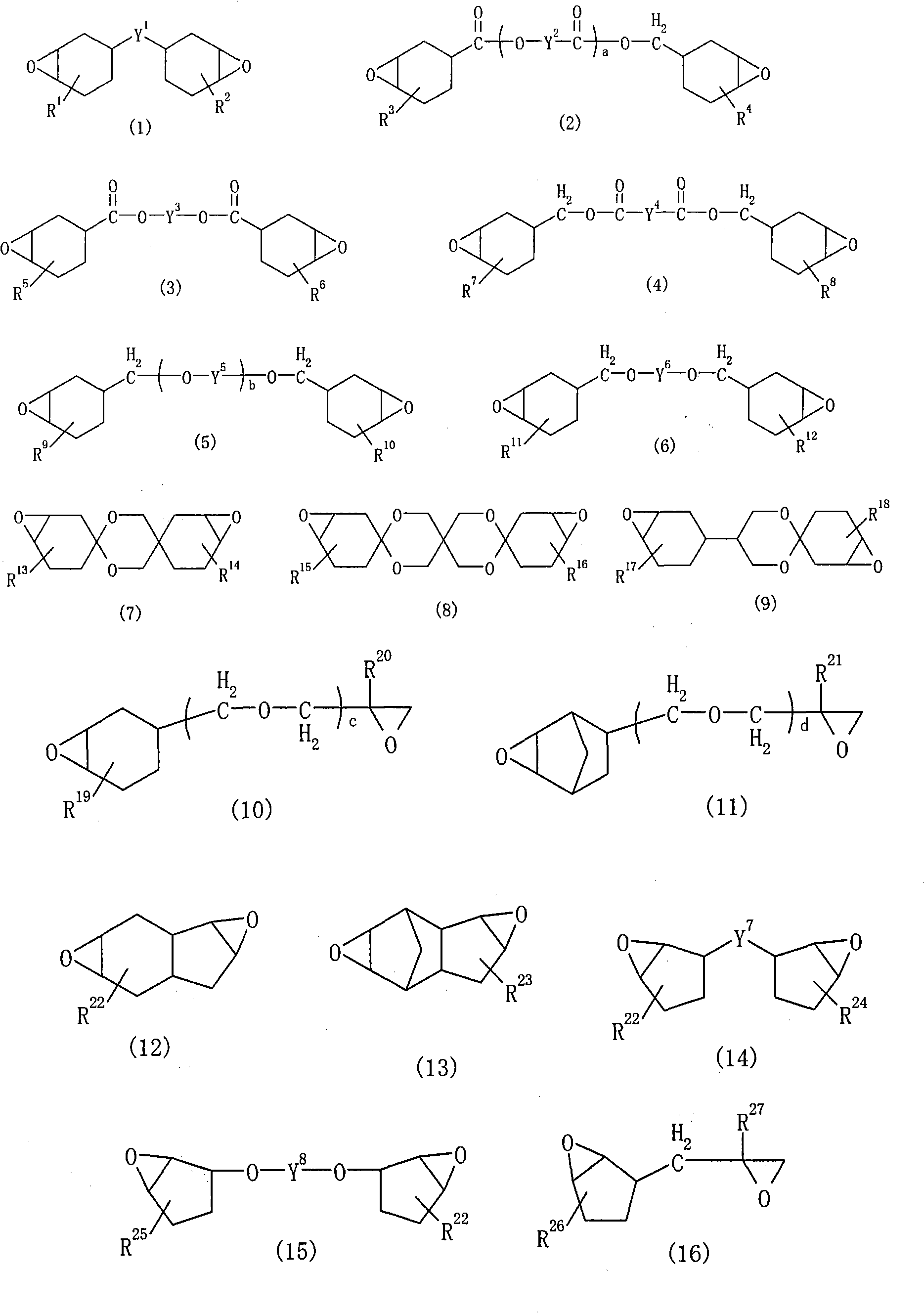

[0179] After mixing the ingredients described in Table 1, defoaming was performed to obtain the adhesives in Examples 1 and 2 as photocurable adhesives of the present invention. However, the photocationic polymerization initiator (C) was mix|blended as a 50 mass % propylene carbonate solution. Among them, the epoxy resin (A), epoxy resin (B), photocationic polymerization initiator (C), polymerizable monomer (D), and additive component (E) in the table described later have the same as above in the present invention. Meaning of said definition. Wherein, the epoxy resin (A) (that is a-1, a-2, a-3, a-4) and epoxy resin (B) (that is b-1, b) that will be used in Examples and Comparative Examples -2, b-3, b-4, b-5) structures are shown in the following formulae.

[0180]

[0181] On the other hand, after mixing the ingredients described in Table 1, defoaming was performed to obtain the adhesives in Comparative Examples 1 and 2 a...

Embodiment 3、 comparative example 3~7

[0191] After mixing the components described in Table 2, defoaming was performed to obtain the adhesive in Example 3 as the photocurable adhesive of the present invention, and as the photocurable adhesive for comparison to obtain Comparative Example 3, the adhesive in 4. However, the photocationic polymerization initiator (C) was mix|blended as a 50 mass % propylene carbonate solution.

[0192] In addition, after mixing the ingredients described in Table 2, defoaming was performed to obtain the adhesives in Comparative Examples 5 to 7 as thermosetting adhesives for comparison. Among them, the thermal cationic polymerization initiator was mixed as a 66% by mass propylene carbonate solution.

[0193] The photocurable adhesive and thermosetting adhesive obtained above were evaluated for the coloring property which is a characteristic which greatly affects whether it can be applied to an optical film. In order to clarify the difference in color tone, each adhesive is sandwiched ...

Embodiment 4~24

[0206] After mixing the components described in Tables 3 to 9, defoaming was performed to obtain the adhesives in Examples 4 to 24 as the photocurable adhesive of the present invention. Among them, the photocationic polymerization initiator (C) was destroyed into a 50 mass % propylene carbonate solution.

[0207] Using a 10 μm bar coater, apply the above-obtained adhesive to an 80 μm-thick UV absorber-containing TAC film (trade name: Fujitech) used as a protective film, and stick polyvinyl alcohol on it. - Iodine polarizer. In addition, using a 10 μm bar coater, each adhesive was coated on a 70 μm thick stretched norbornene film (trade name ZEONOR) manufactured by OPTES Co., Ltd. that had been subjected to a corona discharge treatment to serve as a protective film. The surface of the polarizing plate opposite to the surface to which the TAC film was bonded was bonded, and protective films were bonded to both surfaces of the polarizing plate. For this, an ultraviolet irradiat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com