Oil-water separation device for treating oil-containing wastewater

An oil-water separation device and a technology for oil-water separation, applied in the field of water treatment, can solve the problems of increased oily sewage treatment cost, easy blockage of oil-gathered filter elements, increased labor intensity, etc., to achieve good oil-water separation effect, improve oil removal effect, and reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

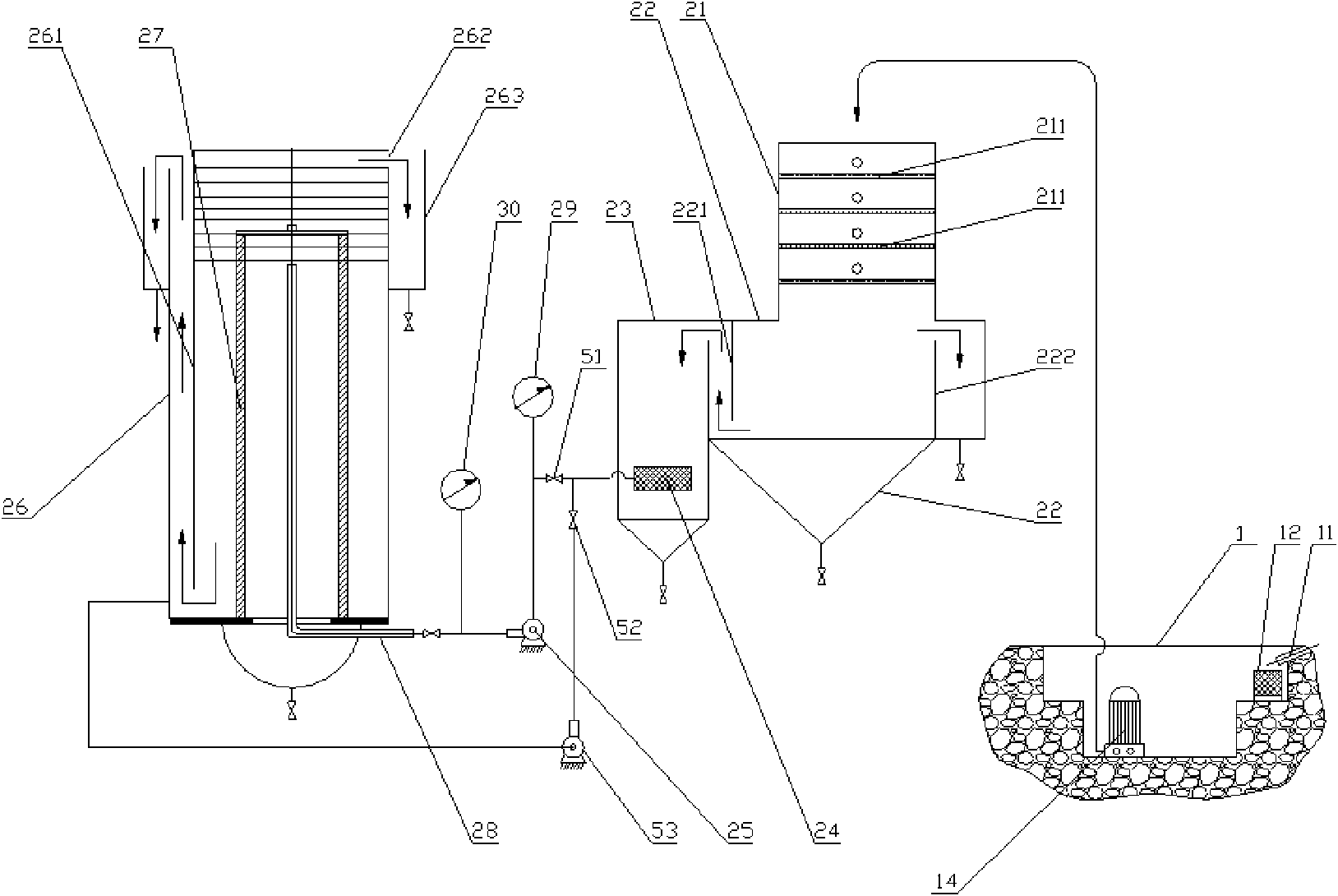

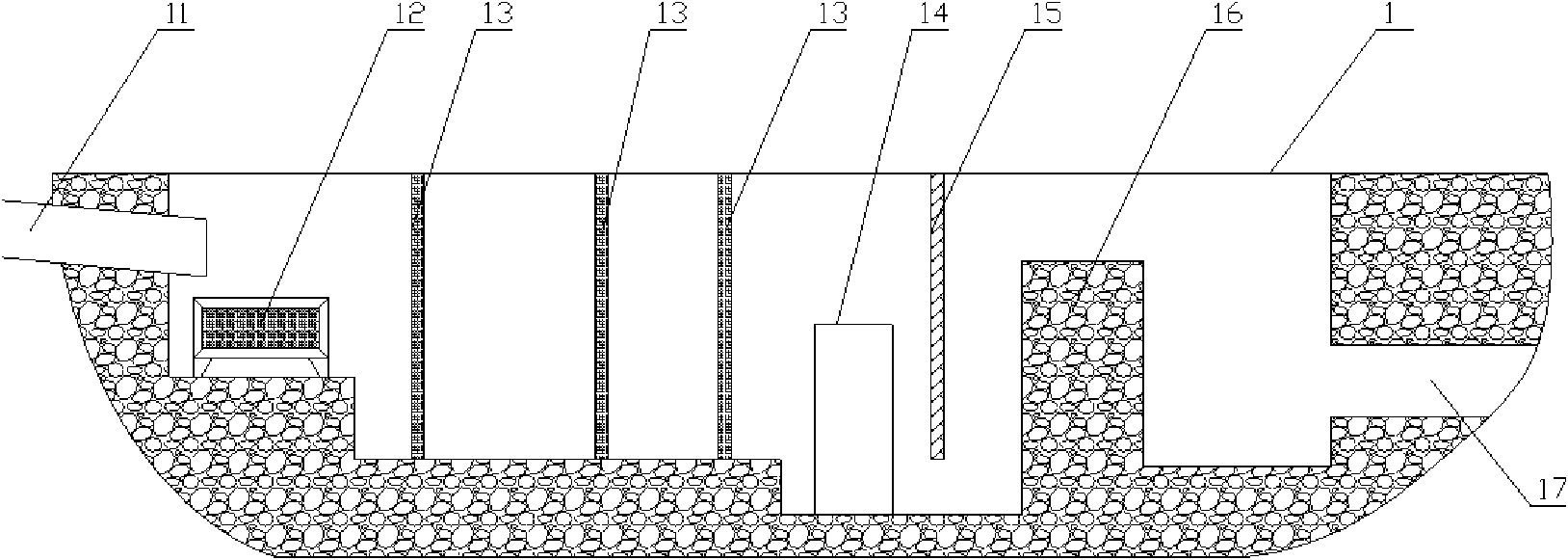

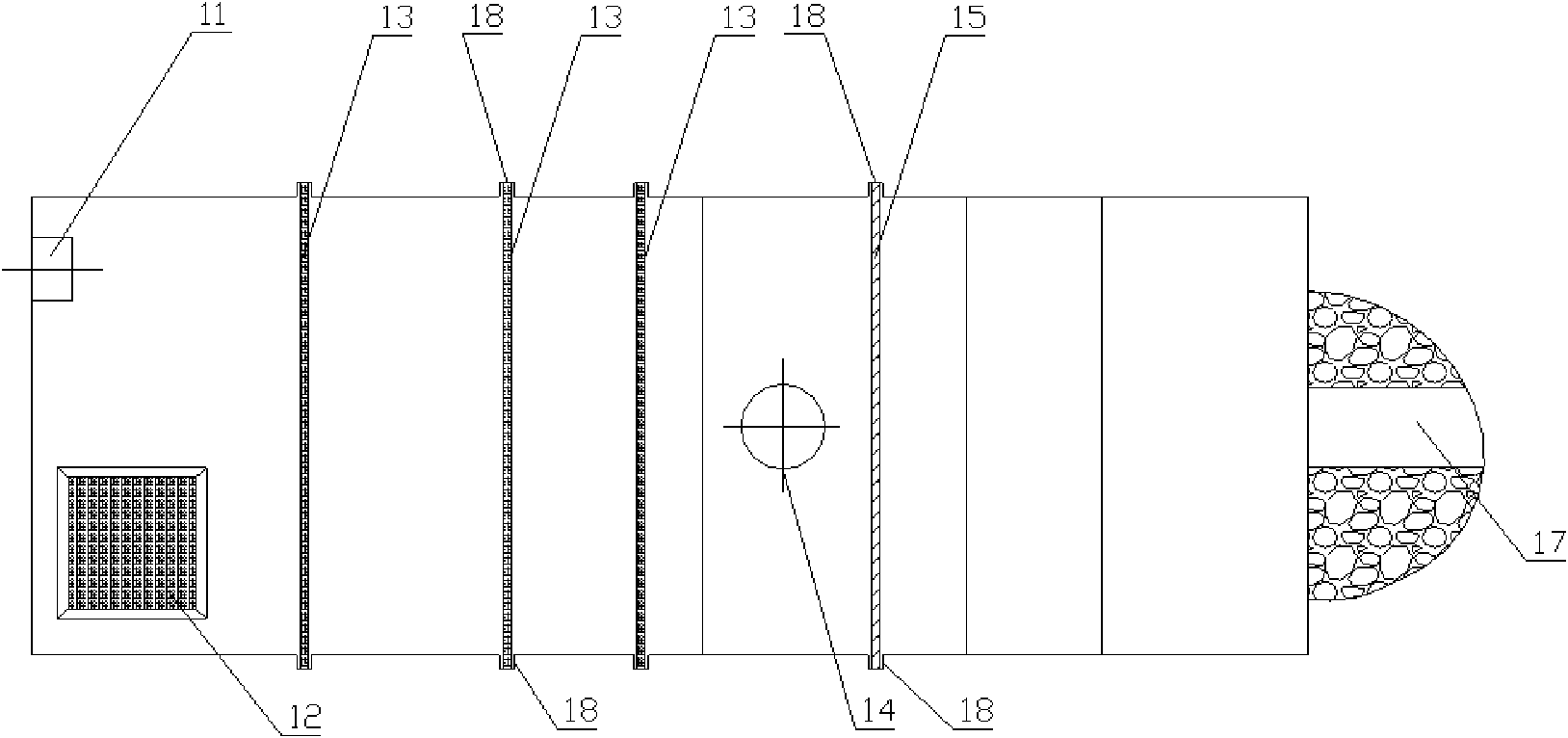

[0047] Such as Figure 4 As shown, an oil-water separation device for treating oily wastewater has a multi-stage oil-water separation structure as a whole, including a sewage filter tank 1 and an oil-water separation host. This embodiment is basically the same as Embodiment 1, the difference is:

[0048] The I-stage oil tank 22 is provided with a dividing plate 221, an oil spill port 223 and an inner tank body 224, and the upper end of the dividing plate 221 is connected with the tank body of the I-stage oil tank 22, and the bottom of the dividing plate 221 is connected with the I-stage oil tank 22. A drainage opening is provided between the oil tanks 22 tank bodies, and the oil overflow port 223 is located at the top of the I-stage oil tank 22, and the inner tank body 224 is a cylinder with an open top, and the bottom of the inner tank body 224 is connected to the I-stage oil tank 22. The tank body is connected, the sewage pump 14 is connected with the upper part of the filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com