Oily sludge treatment system and treatment method thereof

A treatment system and sludge technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problem of expensive chemicals, difficult to remove debris, hindering equipment and Facility operation and other issues, to achieve outstanding results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

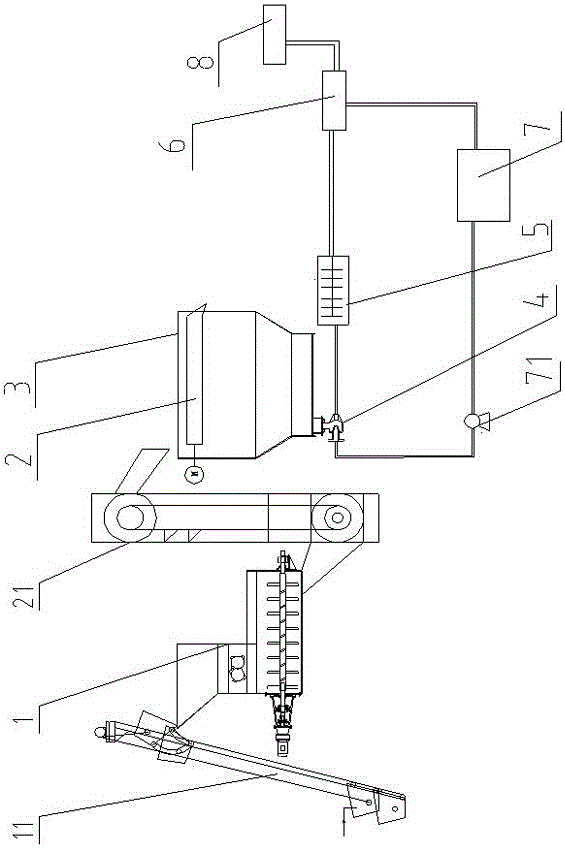

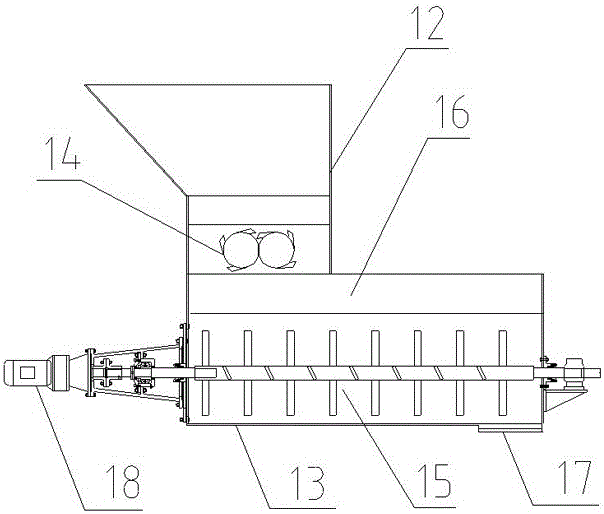

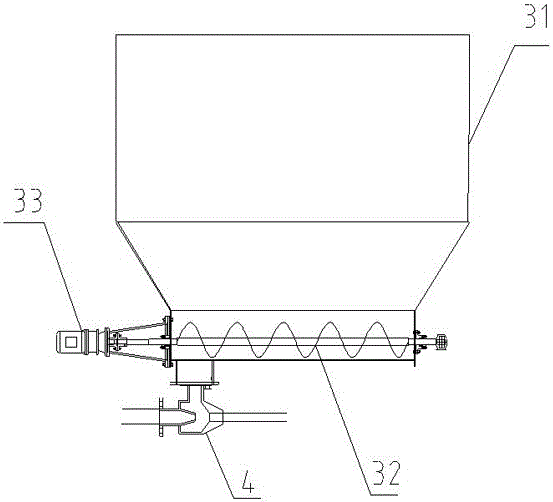

[0103] refer to Figure 1-5 , the present invention will be further illustrated by the following examples.

[0104] The specific embodiment of the present invention is illustrated by taking the oil tank bottom sludge (the sludge contains 30wt% oil, 35wt% water, and the rest is solid matter).

[0105] (1) Transport the oily sludge to the crushing equipment 1 for crushing, and at the same time spray hot water (temperature 80°C) with a high-pressure water spray device to spray and grind the oily sludge. After the crushing equipment 1 completes the crushing and spraying Stand still after washing, then open the first oil slick discharge port and discharge the upper layer of slick oil and sundries (sawdust, grass, plastic, etc.), and the lower layer of oily sludge is discharged and transported to the vibrating screen 2; The weight ratio of the output water to the oily sludge is preferably 1:1.

[0106] (2) The vibrating screen 2 screens the oily sludge, and the debris (bricks, sto...

Embodiment 2

[0111] As another embodiment of the present invention, it is basically the same as the treatment method of Example 1, except that in step (4), the extraction agent is passed into the feed port 617 at the bottom of the separation device, and the extraction agent is toluene, The dosage of the extractant is 0.5wt% of the oily sludge. The final oil recovery rate was 98.3%, and the residual oil rate was 1.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com