Secondary separation cyclone

A technology of secondary separation and cyclone, which is applied in the direction of cyclone device and the device whose axial direction of the cyclone can be reversed, etc. It can solve the problems of poor filtered water quality, increased filter section load, high viscosity of poly-containing sewage, etc. , to achieve the effect of reducing the occupied space, ensuring the treatment effect and enhancing the degreasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

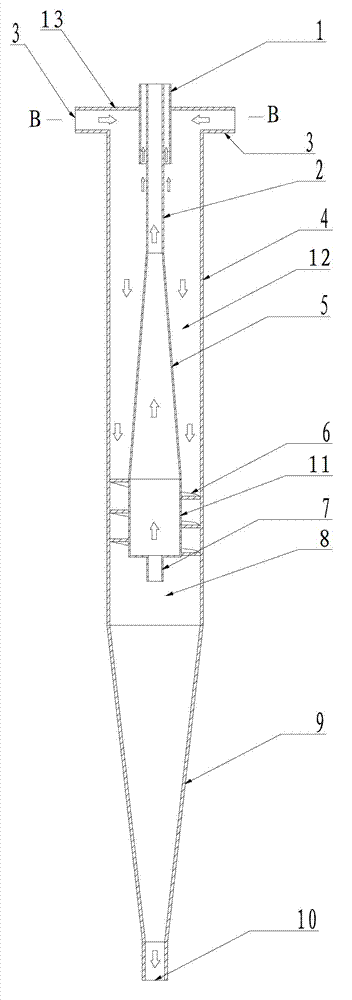

[0012] The present invention will be further described below in conjunction with accompanying drawing:

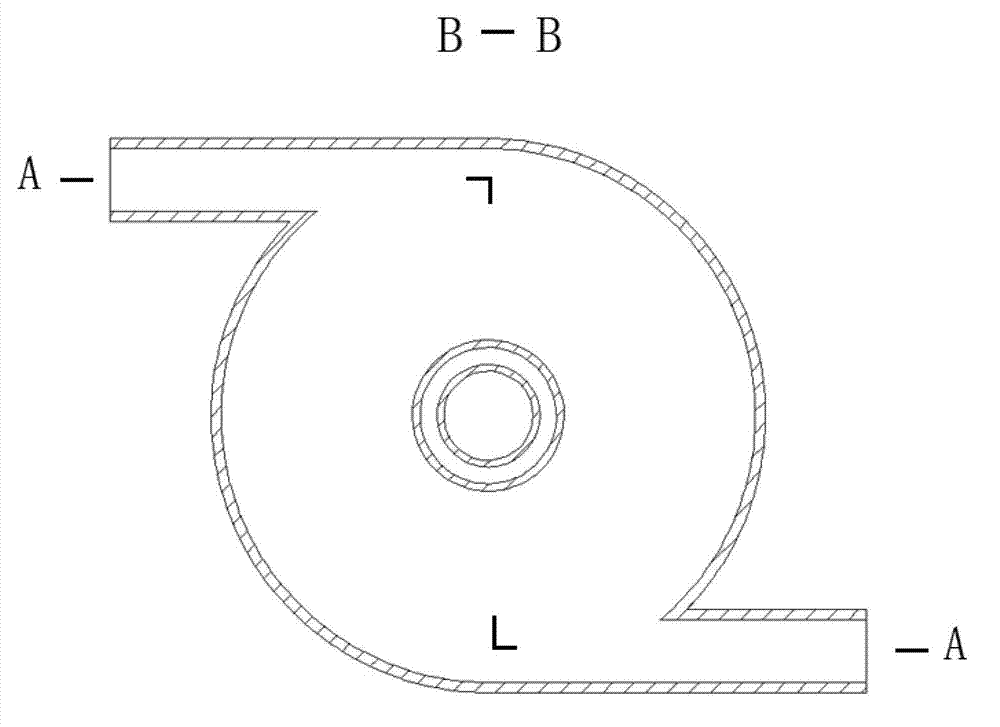

[0013] Depend on Figure 1 to Figure 4 As shown, the specific composition scheme of this secondary separation cyclone is as follows: there is a cylindrical hollow primary swirl tube 4 at the top and an upper end cover 13 for sealing, and the primary swirl tube 4 The upper end sidewall of the separator is provided with inlet pipes 3 that are tangentially connected to the outer circumference of the separator and are opposite to each other and parallel to each other.

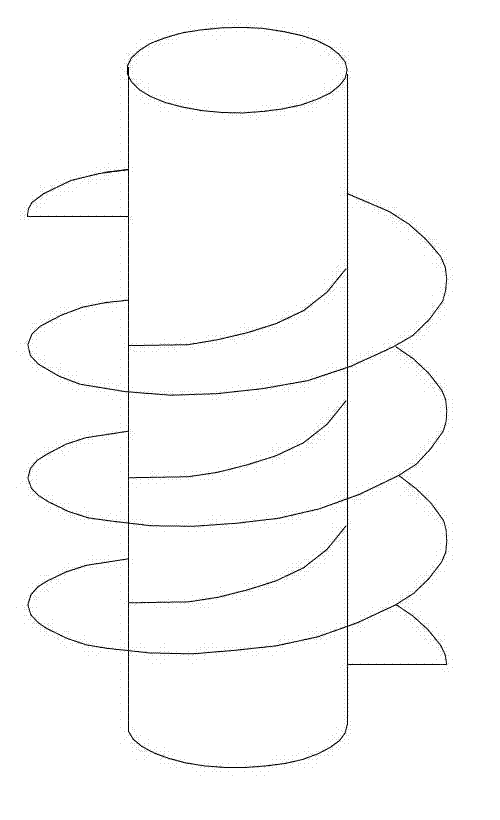

[0014] In addition, a hollow secondary cone section 9 is connected to the lower end of the primary swirl tube 4, and a straight secondary bottom flow tube 10 is connected to the lower end of the secondary cone section 9; A cyclone separation body is fixed in the primary cyclone pipe 4, and the cyclone separation body consists of the secondary overflow pipe 2, the secondary overflow cone section 5, the spiral pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com