Modified treatment method of wood and bamboo, modified wood, modified bamboo and floor

A treatment method and modification technology, applied in the direction of wood treatment, wood treatment details, impregnated wood, etc., can solve the problems of non-corrosion resistance, low strength, reduced application field and use value, etc., and achieve the effect of good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

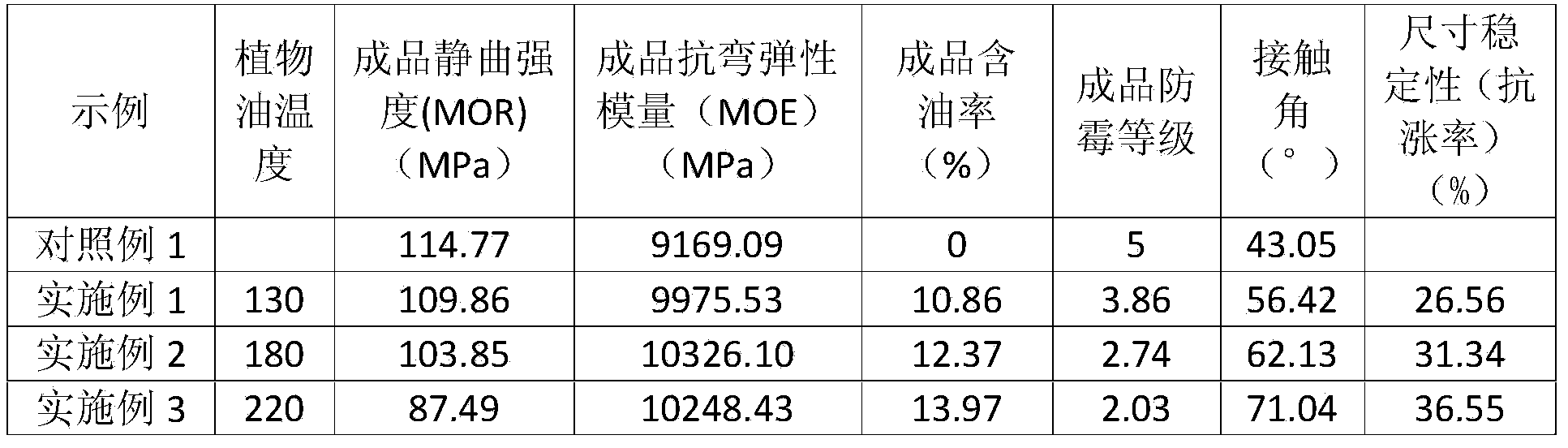

[0021] Embodiment 1-3 (to the modification of bamboo)

[0022] The specific methods for the modification and performance testing of bamboo are as follows.

[0023] a, immerse the bamboo (sheet) with thickness 5mm under the liquid level of the heat treatment tank that soybean oil is housed, heat the heat treatment tank, make vegetable oil reach different temperatures (see Table 1 for details), keep warm for 2h; In the case of cooling, immediately release the vegetable oil in the heat treatment tank, and take out the sheet; c, pre-pressing: heat-press the sheet after oil heat treatment on a hot press at a pressure of 1-2Mpa and a temperature of 110-130°C, and the hot-pressing time 10-20min; d. Surface deoiling treatment: place the pre-pressed sheet in a reaction kettle filled with 75°C absolute ethanol (analytical grade) and soak for 2h, then release ethanol; vacuumize the reaction kettle, after 30min The sheet was taken out, dried at 60°C to obtain the finished product, and th...

Embodiment 4-6

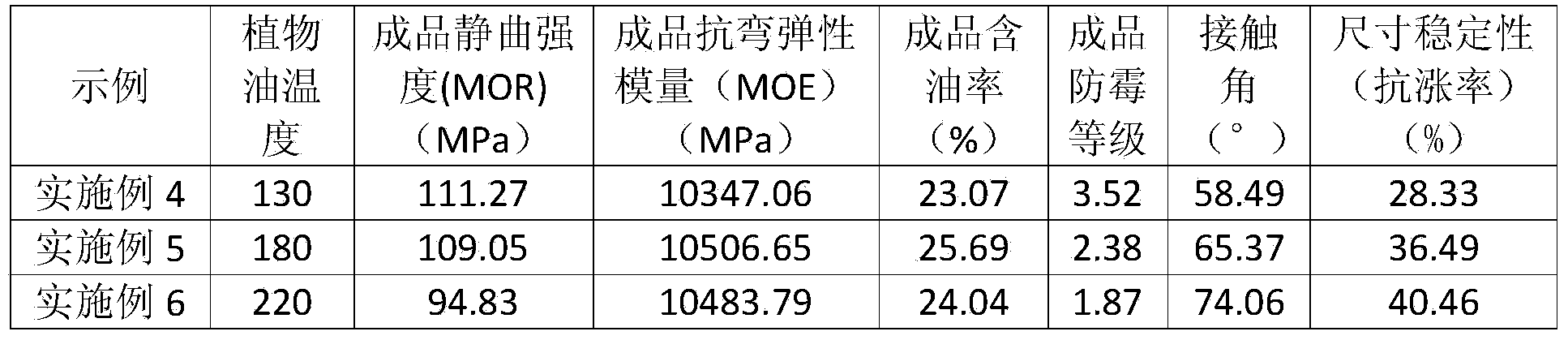

[0025] Embodiment 4-6 (to the modification of bamboo)

[0026] Change the step b in the embodiment 1-3 to "after the vegetable oil is naturally cooled to room temperature, discharge the vegetable oil in the heat treatment tank, and then take out the sheet" to obtain corresponding embodiments 4-6. The detection data of each embodiment is shown in Table 2.

[0027] In Tables 1 and 2, the product mildew resistance level test method: EN24-06-2008 wooden product mildew resistance test method; dimensional stability (expansion resistance) test method: GB / T15780-1995 bamboo material physical and mechanical properties test method. From the contrast of embodiment and corresponding comparative example, especially compare with embodiment 2,5 and comparative example 1, as can be seen, after the bamboo is processed by the method of the present invention, the anti-mildew grade and flexural modulus of bamboo have been improved , but has little effect on the static bending strength of bamboo....

Embodiment 7-12

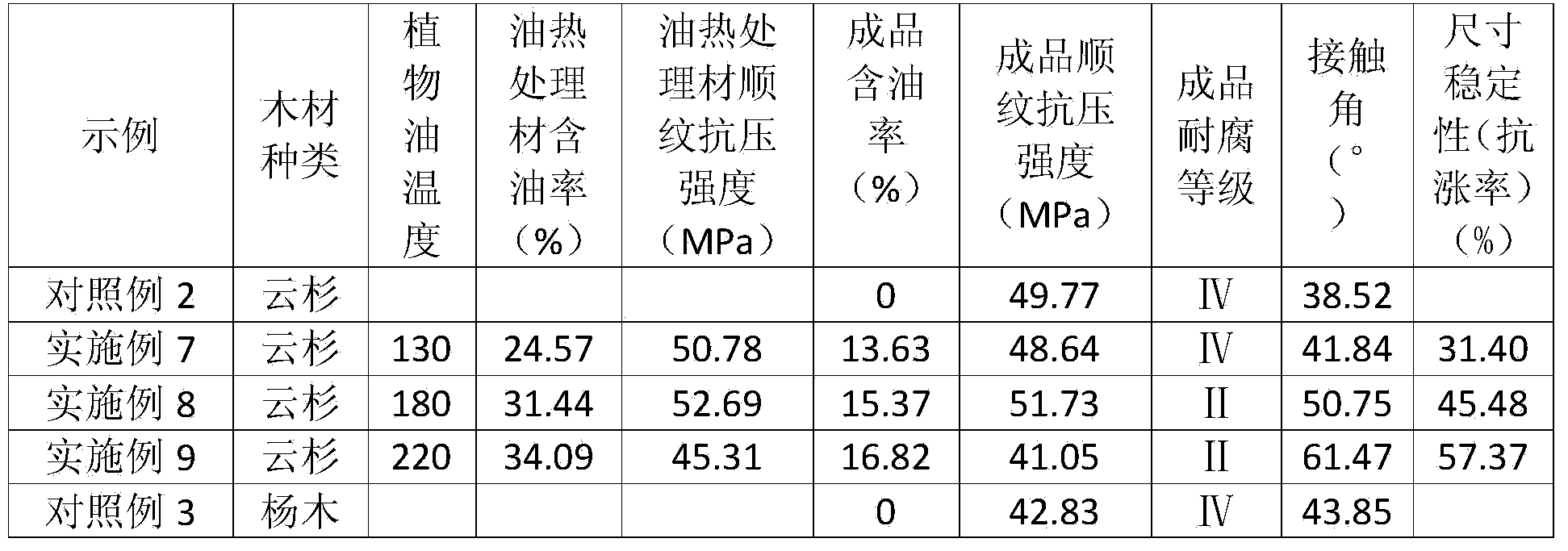

[0028] Embodiment 7-12 (to the modification of wood)

[0029] Modification and performance testing of wood. The specific method is as follows.

[0030] a, immerse different woods (see Table 3) with a thickness of 20 mm under the liquid level of a heat treatment tank equipped with soybean oil, heat the heat treatment tank, make the vegetable oil reach different temperatures, and keep warm for 2 hours; b, when the vegetable oil is not cooled The vegetable oil in the heat treatment tank is released immediately under the situation of the heat treatment tank, and the sheet is taken out to obtain the oil heat treatment material, and its oil content, mechanical properties, etc. are measured, and the specific data are shown in Table 3; , hot pressing on a hot press at a temperature of 110-130 ° C, hot pressing time 10-20 min; d, surface deoiling treatment: place the pre-pressed sheet in a reaction kettle filled with 75 ° C absolute ethanol (analytical pure) Immerse in water for 2 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com