Concrete and preparation method thereof

A concrete and cement technology, applied in the field of concrete and its preparation, to improve mechanical properties, reduce the amount of mixing water, and alleviate the contradiction between supply and demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

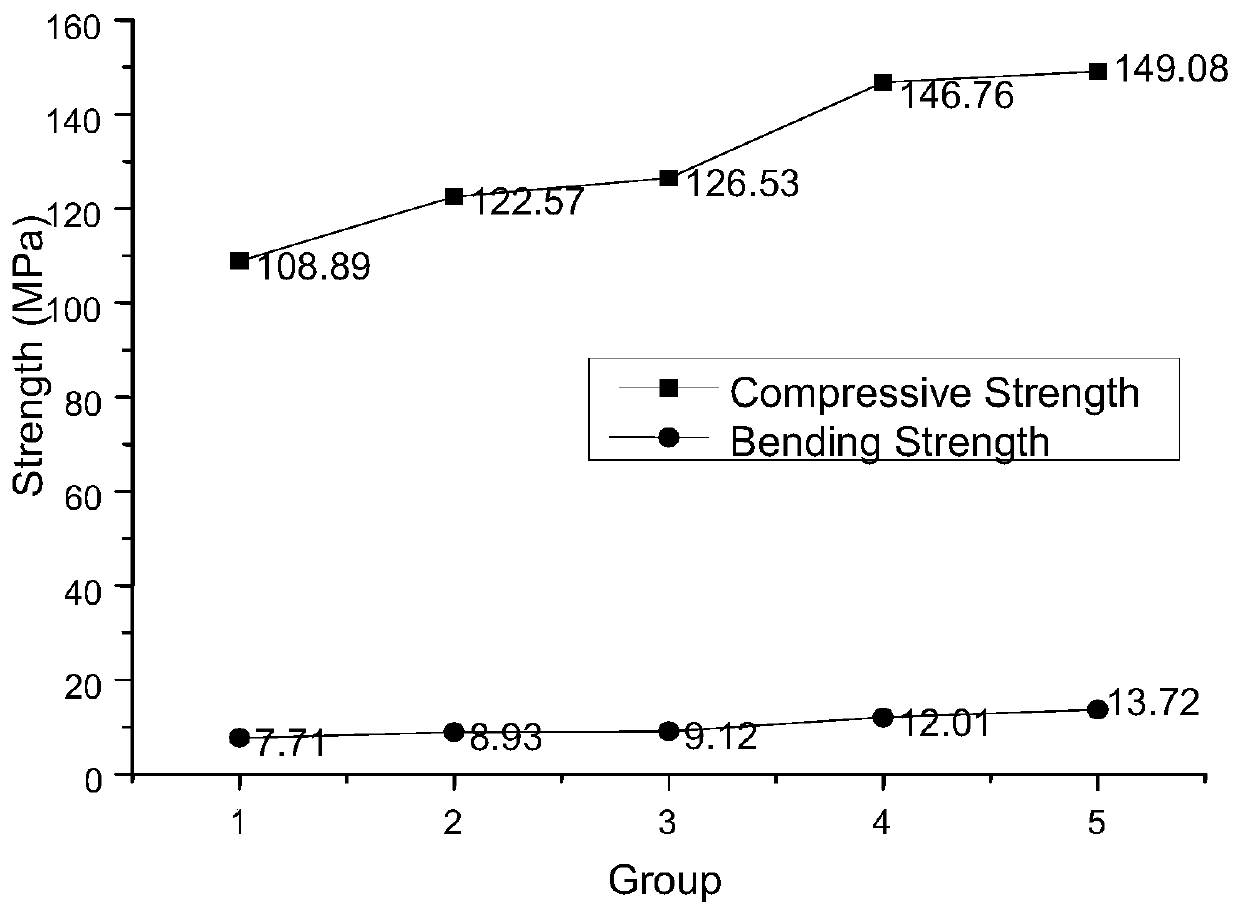

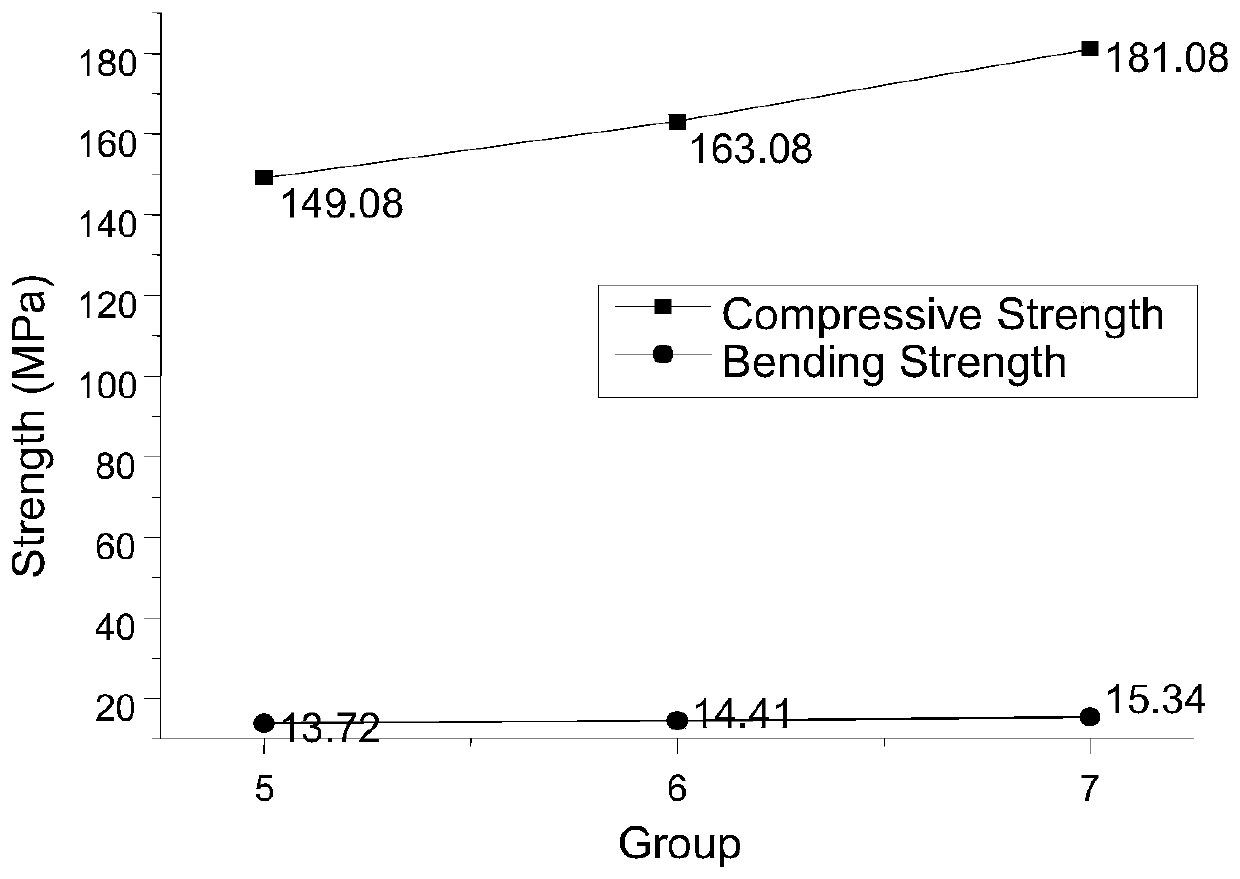

Examples

Embodiment 1

[0026] The concrete material that the embodiment of the present invention provides comprises the raw material of following weight portion:

[0027] 50 parts of cement;

[0028] 20 parts of silica fume;

[0029] 20 parts of fly ash;

[0030] 10 parts of slag fine powder;

[0031] 140 parts of river sand with a fineness modulus of 2.2-2.5 and a mud content of 1%-5%;

[0032] 0 parts of desert sand with a diameter ranging from 0.25 to 0.05 mm;

[0033] 15 parts of anti-rust steel fibers with a diameter of 0.1-0.3 mm, a length of 10-15 mm, and a tensile strength ≥ 2850 MPa;

[0034] 3 parts of polycarboxylate superplasticizer;

[0035] 15 parts of water.

[0036] Wherein, the anti-rust steel fiber may be copper-plated steel fiber.

[0037] The preparation method of concrete in the present embodiment comprises the steps:

[0038] Prepare cement, silica fume, fly ash, slag powder, anti-rust steel fiber, river sand and desert sand according to the above weight parts, add them...

Embodiment 2

[0043] The difference between this embodiment and embodiment 1 is that the concrete is prepared by mixing the following raw materials in parts by weight:

[0044] 50 parts of cement;

[0045] 20 parts of silica fume;

[0046] 20 parts of fly ash;

[0047] 10 parts of slag fine powder;

[0048] 105 parts of river sand with a fineness modulus of 2.2-2.5 and a mud content of 1%-5%;

[0049] 35 parts of desert sand with a diameter ranging from 0.25 to 0.05 mm;

[0050] 15 parts of anti-rust steel fibers with a diameter of 0.1-0.3 mm, a length of 10-15 mm, and a tensile strength ≥ 2850 MPa;

[0051] 3 parts of polycarboxylate superplasticizer;

[0052] 15 parts of water.

[0053] Wherein, the anti-rust steel fiber may be copper-plated steel fiber.

[0054] The preparation method of concrete in the present embodiment comprises the steps:

[0055] Prepare cement, silica fume, fly ash, slag powder, anti-rust steel fiber, river sand and desert sand according to the above weight...

Embodiment 3

[0061] The difference between this embodiment and embodiment 1 is that the concrete is prepared by mixing the following raw materials in parts by weight:

[0062] 50 parts of cement;

[0063] 20 parts of silica fume;

[0064] 20 parts of fly ash;

[0065] 10 parts of slag fine powder;

[0066] 70 parts of river sand with a fineness modulus of 2.2-2.5 and a mud content of 1%-5%;

[0067] 70 parts of desert sand with a diameter ranging from 0.25 to 0.05 mm;

[0068] 15 parts of anti-rust steel fibers with a diameter of 0.1-0.3 mm, a length of 10-15 mm, and a tensile strength ≥ 2850 MPa;

[0069] 3 parts of polycarboxylate superplasticizer;

[0070] 15 parts of water.

[0071] Wherein, the anti-rust steel fiber may be copper-plated steel fiber.

[0072] The preparation method of concrete in the present embodiment comprises the steps:

[0073] Prepare cement, silica fume, fly ash, slag powder, anti-rust steel fiber, river sand and desert sand according to the above weight pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com