Comprehensive utilization method of olefin in Fischer-Tropsch-synthesized light distillate

A technology of light distillate oil and Fischer-Tropsch synthesis, applied in distillation purification/separation, preparation of ether by addition of unsaturated compounds, organic chemistry, etc., can solve problems such as air pollution, reduce consumption, and alleviate the contradiction between supply and demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

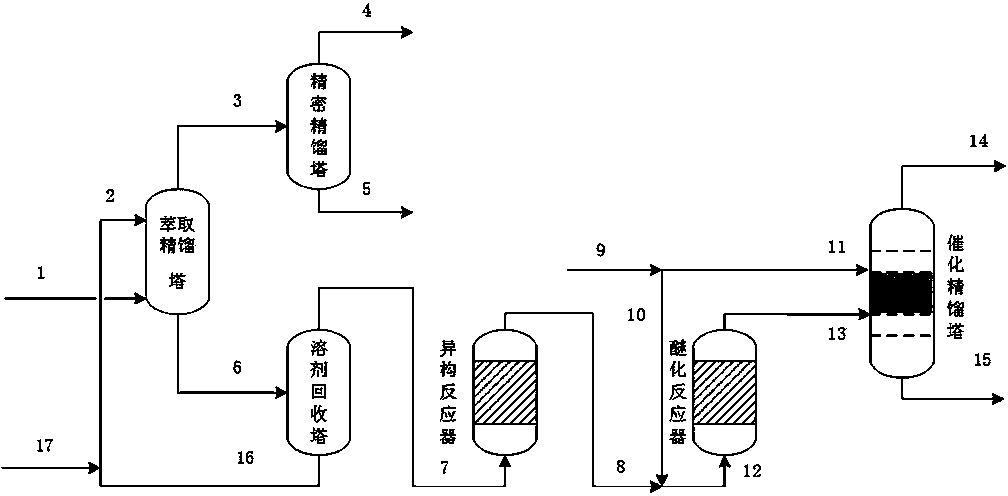

[0028] Fischer-Tropsch light C5 distillate oil 1 enters an extractive distillation tower with a theoretical plate number of 74, the extraction agent selected is N, N-dimethylformamide (DMF), the reflux ratio is 8.5, and the feed position is (from From top to bottom, the same below) 3 and 20, a stream 3 rich in 1-pentene is obtained from the top of the extractive distillation tower, and a stream 6 of extractant and raffinate carbon five components is obtained from the bottom of the extractive distillation tower; The weight ratio of the raw material and the extractant is 15:1, the feed temperature of the extractant is 20°C, the temperature at the top of the tower is 25°C, the temperature at the bottom of the tower is 55°C, and the operating pressure is normal pressure.

[0029] The stream 3 enters a precision rectification tower with a theoretical plate number of 214, the reflux ratio is 10.54, and the feed position is 152, and the refined stream 4 of 1-pentene can be obtained fr...

Embodiment 2

[0038] Fischer-Tropsch light C5 distillate oil 1 enters the extractive distillation tower with a theoretical plate number of 74. The extraction agent selected in this implementation case is N,N-dimethylformamide (DMF), the reflux ratio is 9, and the feed The positions are (from top to bottom, the same below) 3 and 20, the stream 3 rich in 1-pentene is obtained from the top of the extractive distillation tower, and the extractant and raffinate carbon five components are obtained from the bottom of the extractive distillation tower Stream 6; the weight ratio of the raw material and the extractant is 20:1, the feed temperature of the extractant is 30°C, the temperature at the top of the tower is 40°C, the temperature at the bottom of the tower is 70°C, and the operating pressure is normal pressure.

[0039] The stream 3 enters a precision rectification tower with a theoretical plate number of 178, the reflux ratio is 13, and the feed position is 126, and the refined stream 4 of 1-...

Embodiment 3

[0048] Fischer-Tropsch light C5 distillate oil 1 enters the extractive distillation tower with a theoretical plate number of 74. The extraction agent selected in this implementation case is N, N-dimethylformamide (DMF), the reflux ratio is 10, and the feed The positions are (from top to bottom, the same below) 3 and 20, the stream 3 rich in 1-pentene is obtained from the top of the extractive distillation tower, and the extractant and raffinate carbon five components are obtained from the bottom of the extractive distillation tower The stream 6; the weight ratio of the raw material and the extractant is 18:1, the feed temperature of the extractant is 25°C, the temperature at the top of the tower is 30°C, and the temperature at the bottom of the tower is 60°C.

[0049] The stream 3 enters a precision rectification tower with a theoretical plate number of 162, the reflux ratio is 15, and the feed position is 115, and the refined stream 4 of 1-pentene can be obtained from the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com