Strip-shaped solid wood mortise and tenon combined mosaic structure laminated wood

A mosaic structure and glulam technology, which is applied in the direction of wood processing appliances, wooden veneer joints, manufacturing tools, etc., can solve the problems of unreasonable use of scale, increase the supply of solid wood glulam, and cumbersome processing techniques, etc., to achieve Novel concept, improved strength, and large bonding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

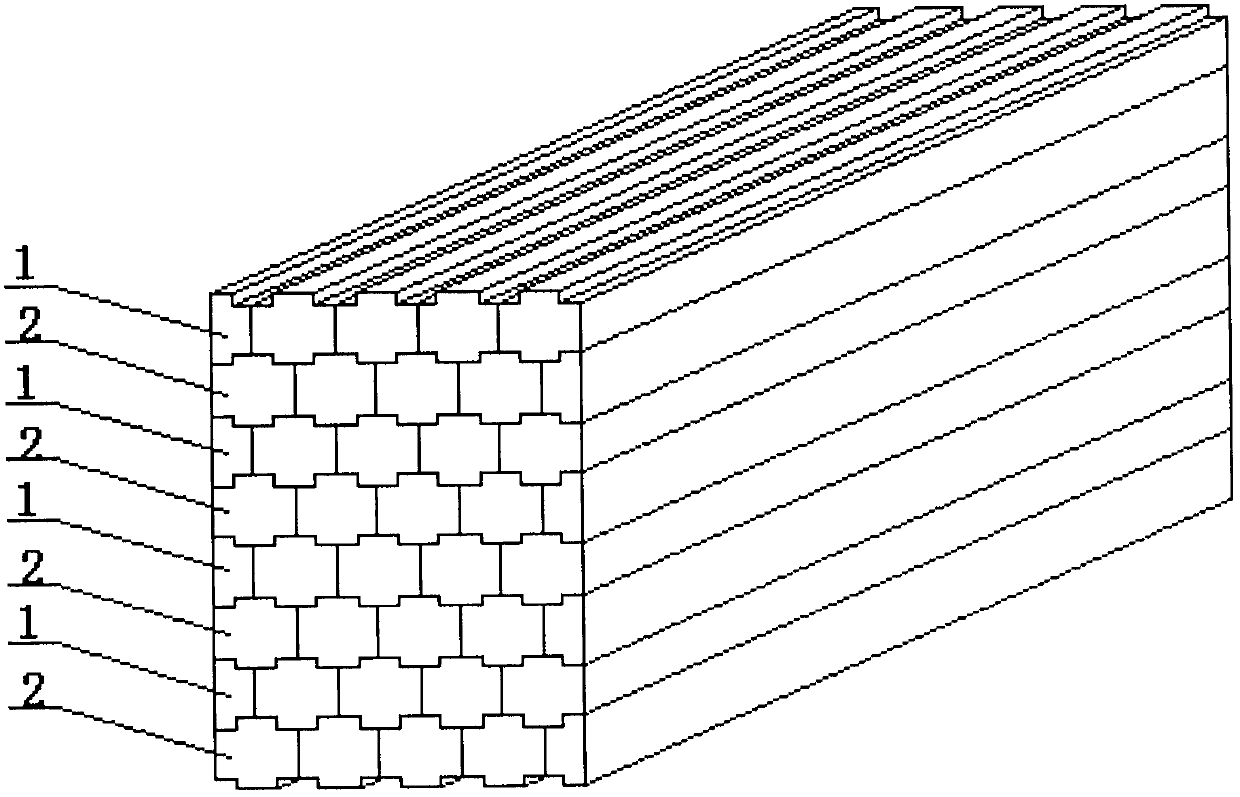

[0040] Combine 10 pieces of splicing board one (1) and 10 pieces of splicing board two (2). After the socket surface is glued, the corresponding composite mosaic is press-molded to obtain a shape such as figure 1 The thin-strip solid wood mortise and tenon composite mosaic structure glulam finished product.

Embodiment 2

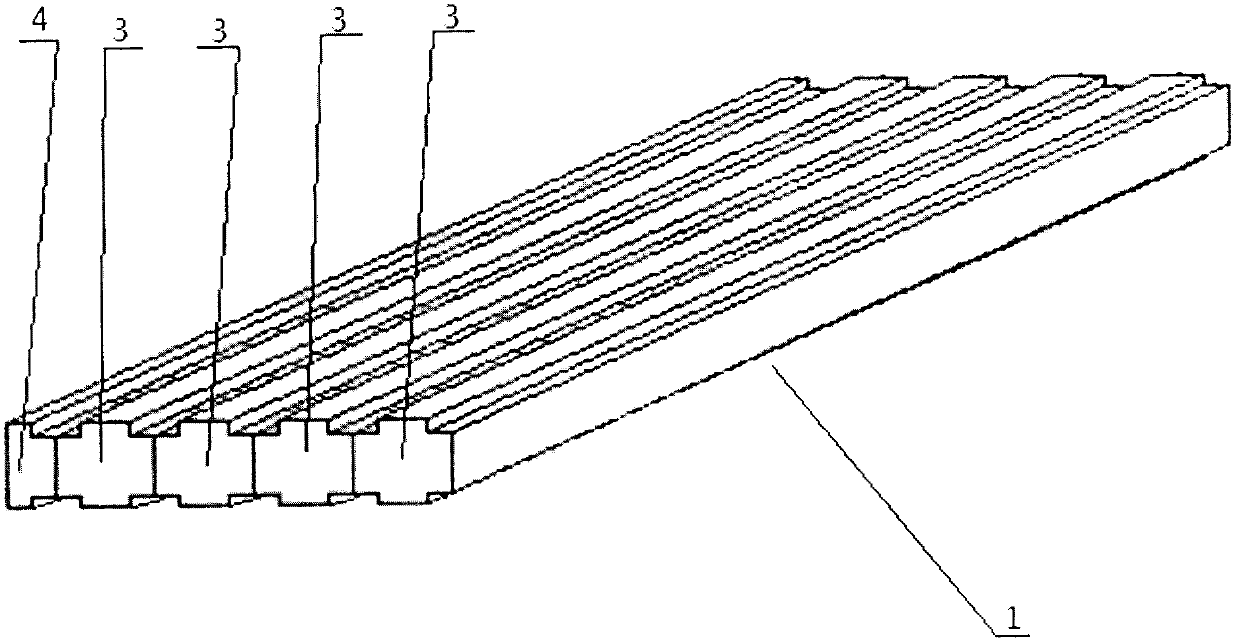

[0042] The manufacturing method of thin-strip solid wood mortise and tenon composite mosaic structure glulam, the material is veneer, plywood manufacturer's production of veneer, plywood remaining eucalyptus, pine, poplar, and other wood thin strips (diameter 2-3CM) cylindrical wood core Shaft, what this embodiment adopts is long 127CM, diameter 2.5CM and diameter 2.8CM eucalyptus thin strip cylindrical wood mandrel dry material is produced together, and the size of the finished thin strip type solid wood mortise and tenon composite mosaic structure glulam is long 127CM, wide 19.95CM, 17.4CM high.

[0043] 1. Preparation of splice board 1

[0044] (1) Preparation of cross-shaped wooden strips:

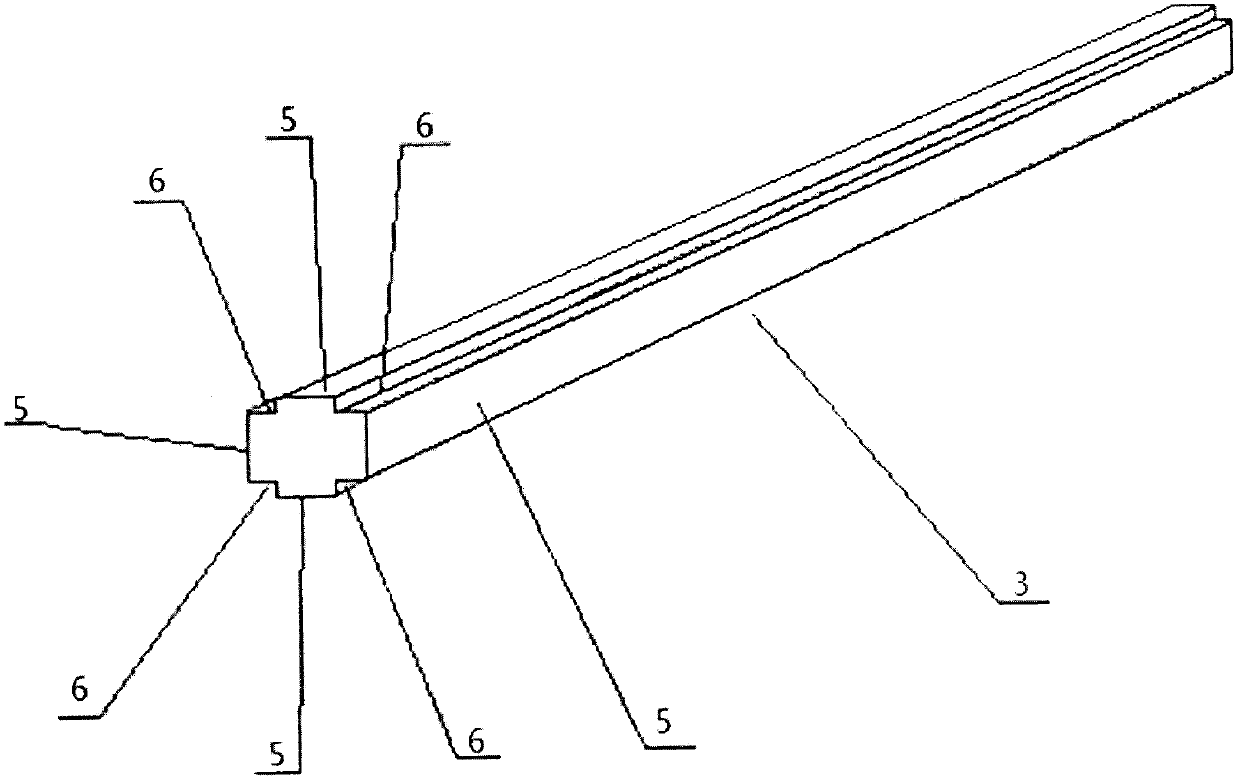

[0045] Use a four-sided planer to process the eucalyptus thin cylindrical wooden mandrel with a diameter of 2.5CM into a length of 127CM, a width of 2.1CM, and a height of 2.1CM. A cross-shaped wooden strip (3) with a groove depth of 0.4CM and a width of 0.525CM;

[0046] (2) Prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com