Process for abstracting floating air ball from fly ash or slag

A technology for fly ash and slag, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of resource interconnection, integration, high extraction cost, and unsystematic extraction research, so as to change the distribution pattern. , alleviate the contradiction between supply and demand, and broaden the effect of source channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

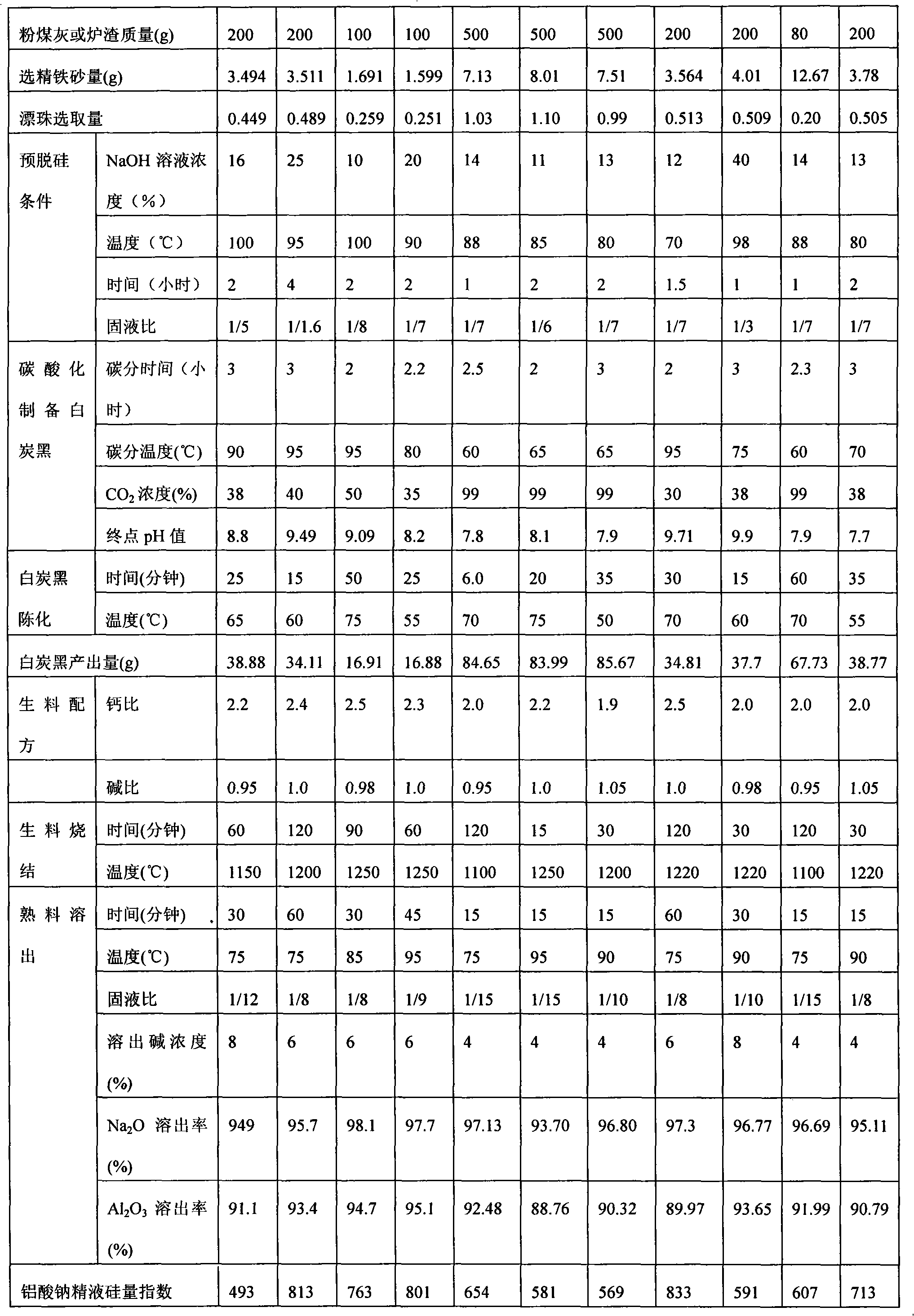

[0054] In order for those skilled in the art to further understand the features and technical contents of the present invention, please refer to the following detailed description and accompanying drawings of the present invention. The accompanying drawings are provided for reference and illustration only, and are not intended to limit the present invention.

[0055] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

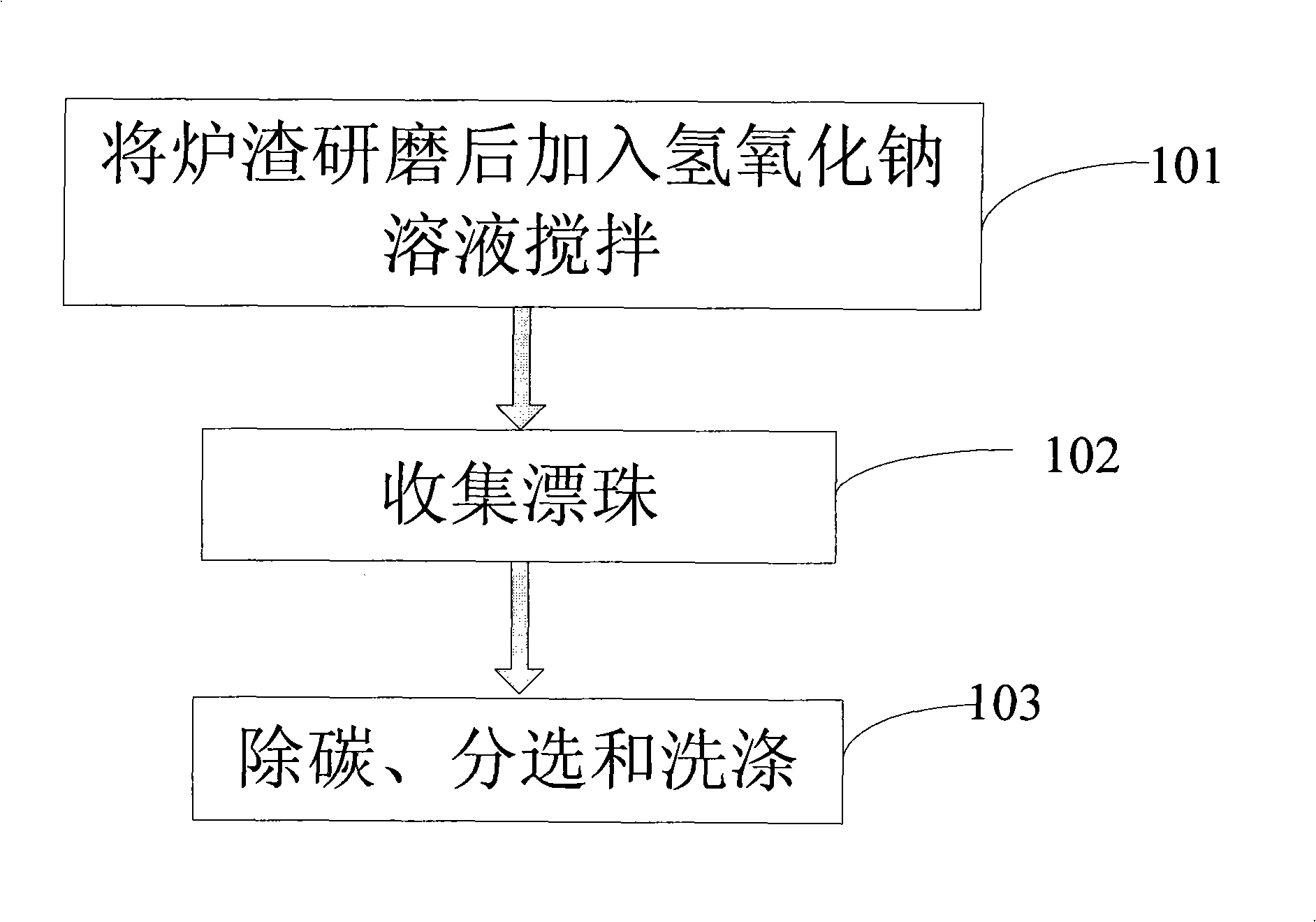

[0056] Such as figure 1 As shown, when extracting floating beads from fly ash or slag, it can be achieved through the following steps:

[0057] 101: After grinding the slag, magnetically separating the fine iron ore from the dry fly ash or slag, according to the solid-liquid ratio: the volume ratio of the fly ash or slag mass (kg) to the sodium hydroxide solution for pre-desilication ( liter) is 1:1.6~1:8 for proportioning, adding mass percentage is 10%~40% NaOH solution; Start the stirring equipment at n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com