Method for preparing gasoline blending composition from Fischer-Tropsch synthesis oil-phase product

A Fischer-Tropsch synthesis and product technology, which is used in the preparation of liquid hydrocarbon mixtures, the treatment of hydrocarbon oils, and the petroleum industry, and can solve the problems of difficulty in obtaining gasoline blending components with reasonable properties and inability to inherit aromatic components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

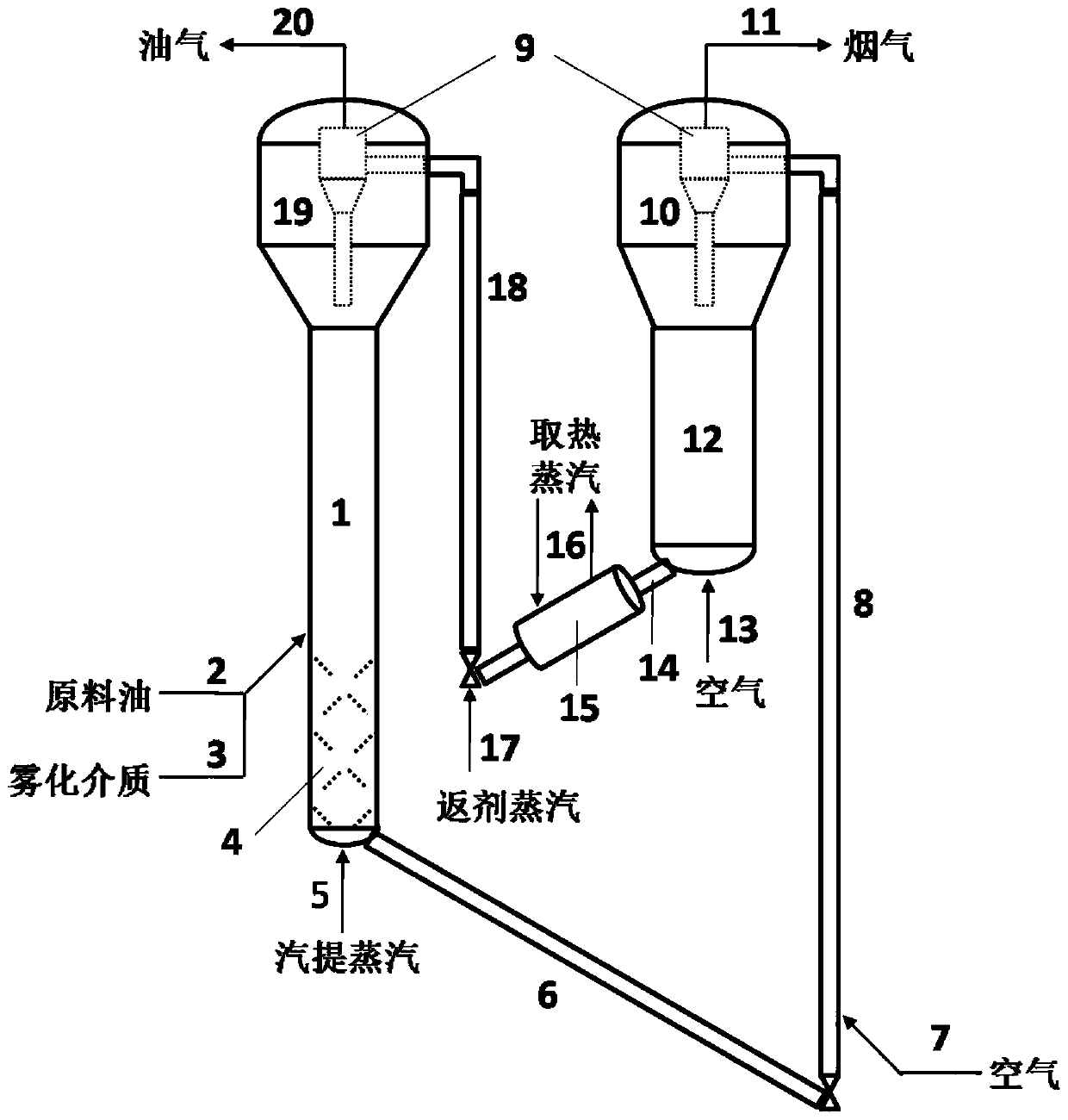

[0076] In this example, Fischer-Tropsch synthesis products greater than 350°C are used as raw materials, and the attached figure 1The fluidized bed process shown performs catalytic conversion to produce gasoline blending components. The Fischer-Tropsch synthesis product greater than 350°C is used as raw material oil 2 and preheated to 270°C, atomized by water vapor (that is, the atomization medium 3) and then sprayed upward into the fluidized bed reactor 1 for reaction, and the downstream A cracking reaction occurs when the low-activity catalyst mainly containing carbon-containing unborn catalyst contacts, and the reaction product continues to ascend, and then contacts with a regenerated catalyst-based high-activity catalyst to undergo an aromatization reaction, and the reaction product continues to ascend to the reaction settler 19 to complete After the oil agent is separated, it goes out of the reaction device and enters the fractionation system; the carbon-containing cataly...

Embodiment 2

[0078] In this embodiment, the whole cut Fischer-Tropsch synthesis oil phase product and methanol are used as raw materials, and the attached figure 1 The fluidized bed process shown performs catalytic conversion to produce gasoline blending components. After preheating the full fraction Fischer-Tropsch synthesis oil phase product to 240°C, feed it from the tube layer of the oil inlet nozzle of the fluidized bed reactor 1, and feed the vaporized methanol from the shell layer of the oil inlet nozzle of the fluidized bed reactor 1, Raw oil and vaporized methanol are mixed at the nozzle port to form small mist droplets that are injected into the fluidized bed reactor 1 at a high speed for reaction ( figure 1 The reaction section and the stripping section are connected, the dividing point is at the oil inlet nozzle, the reaction zone is above the nozzle, and the stripping zone is below the nozzle), the reaction pressure is 0.15MPa, the reaction temperature is 450°C, and the mass r...

Embodiment 3

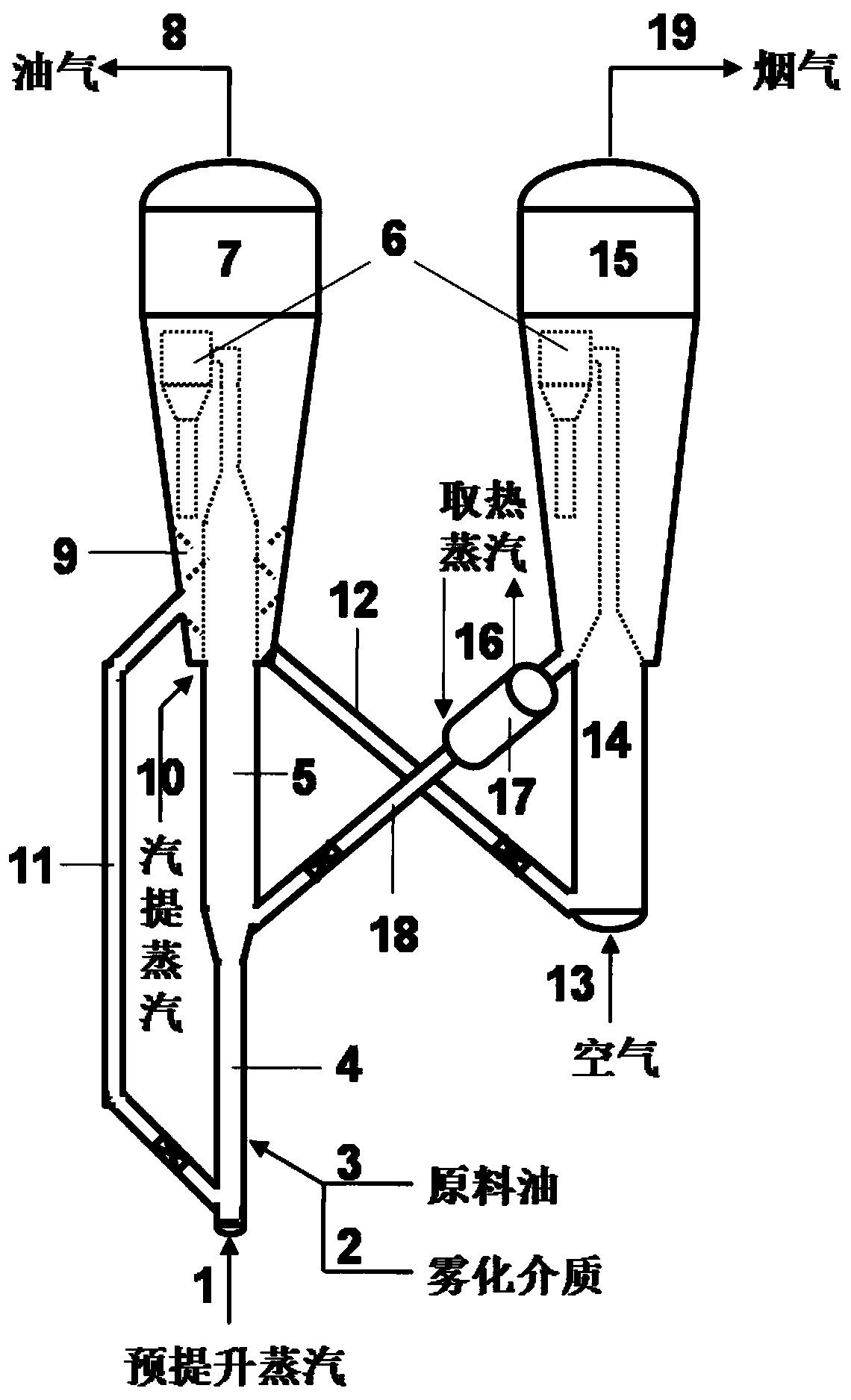

[0080] In this example, the Fischer-Tropsch synthesis product at a temperature greater than 280°C is used as the raw material, and the liquefied gas of the cracked product is coupled to the refining process. figure 2 The fluidized bed process shown performs catalytic conversion to produce gasoline blending components. After preheating the Fischer-Tropsch synthesis product greater than 280°C to 240°C, after steam atomization, the cracking reaction occurs first in the lower fluidized bed reaction zone with the low-activity spent catalyst recycled from the spent agent circulation standpipe 11, The cracked product and the spent agent go up into the upper fluidized bed reaction zone, and then mix with the highly active regenerated catalyst sent by the regeneration inclined pipe 18 to undergo aromatization reaction, and the reaction product and catalyst continue to go up to the reaction settler 7 to complete the oil agent After separation, it enters the fractionation system, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com