Building polymer powder based on composite silicate

A composite silicate and polymer powder technology, which is applied in the field of building materials, can solve the problems that have not been really developed, the production process is complicated, and the energy consumption is high, so as to alleviate the contradiction between supply and demand, save resource consumption, and reduce environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

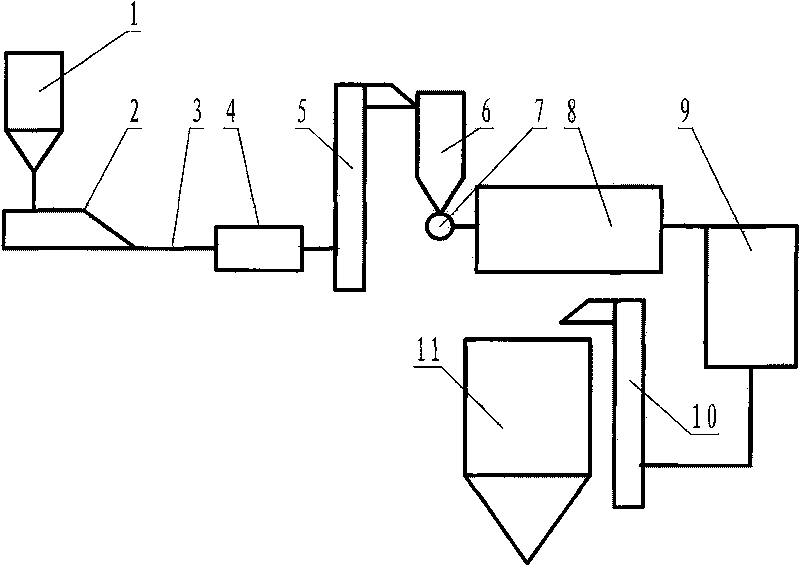

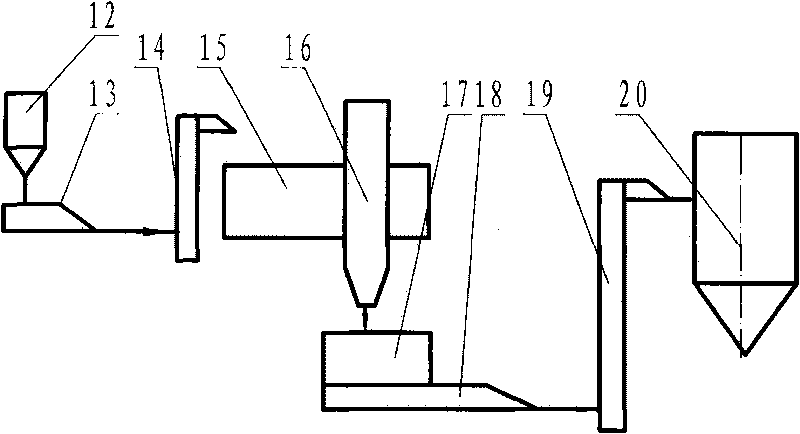

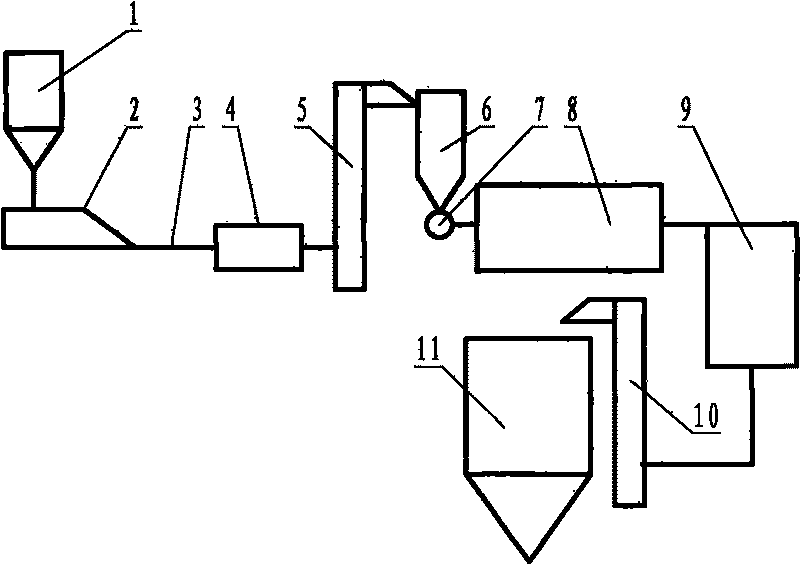

Method used

Image

Examples

Embodiment 1

[0040] Compound silicate-based building polymer powder formula:

[0041] Fly ash: 38wt%, grade 75-95 granulated blast furnace slag powder: 20wt%, ordinary Portland cement: 32wt%, limestone powder: 5wt%, gypsum powder: 4wt%, 1wt% cement grinding aid, national standard It is JC / T667-2004.

Embodiment 2

[0043] Compound silicate-based building polymer powder formula:

[0044] Fly ash: 43wt%, grade 75-95 granulated blast furnace granulated blast furnace slag powder: 20wt%, Portland cement: 27wt%, limestone powder: 5wt%, gypsum powder: 4wt%, 1wt% cement grinding aid , The national standard is JC / T667-2004.

Embodiment 3

[0046] Compound silicate-based building polymer powder formula:

[0047] Fly ash: 33wt%, grade 75-95 granulated blast furnace slag powder: 20wt%, ordinary Portland cement: 37wt%, limestone powder: 5wt%, gypsum powder: 4wt%, 1wt% cement grinding aid, national standard It is JC / T667-2004.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com