Method and equipment for producing cup of beaker

A production device and cup body technology, which is applied in glass production, glass molding, glass reshaping, etc., can solve the problems that affect the appearance and quality of beakers, the beaker body cannot be used, and the labor intensity of workers is high. The effect of contradiction between supply and demand, improvement of appearance and quality, improvement of ability to participate in market competition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0030] The embodiment of the present invention is the example of the beaker cup body of 70mm with making aperture:

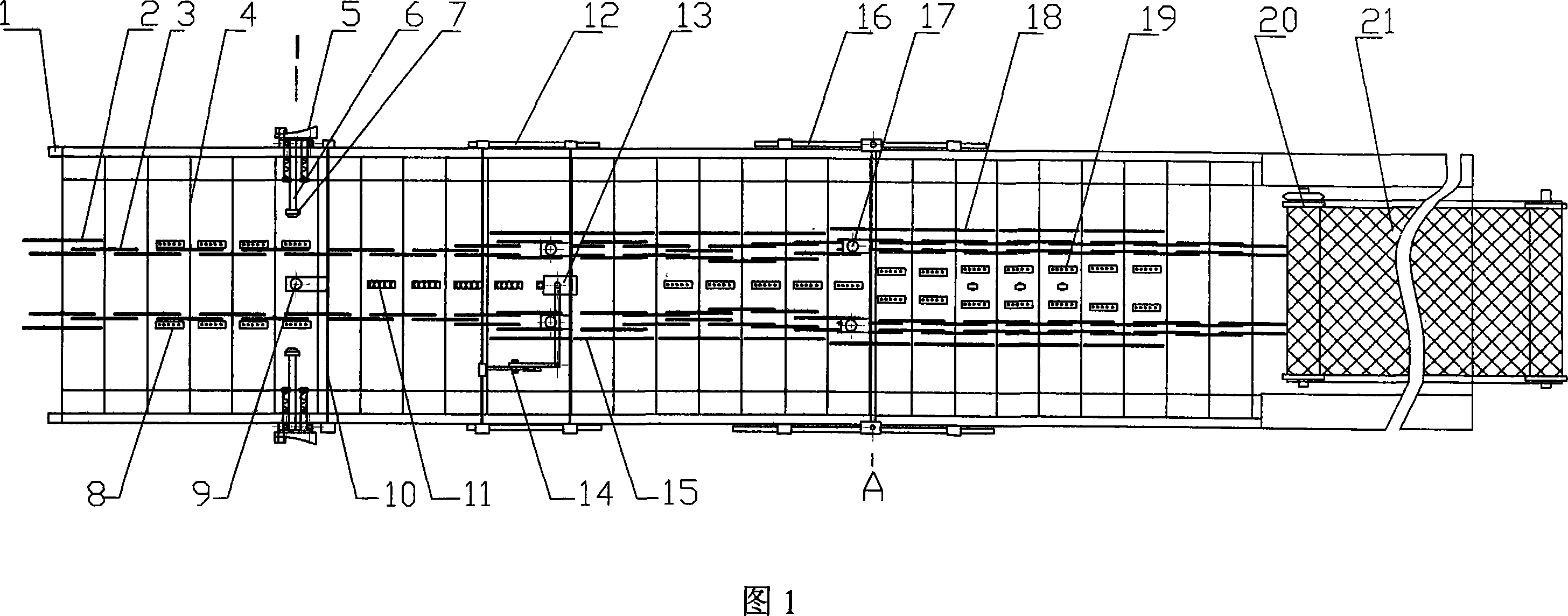

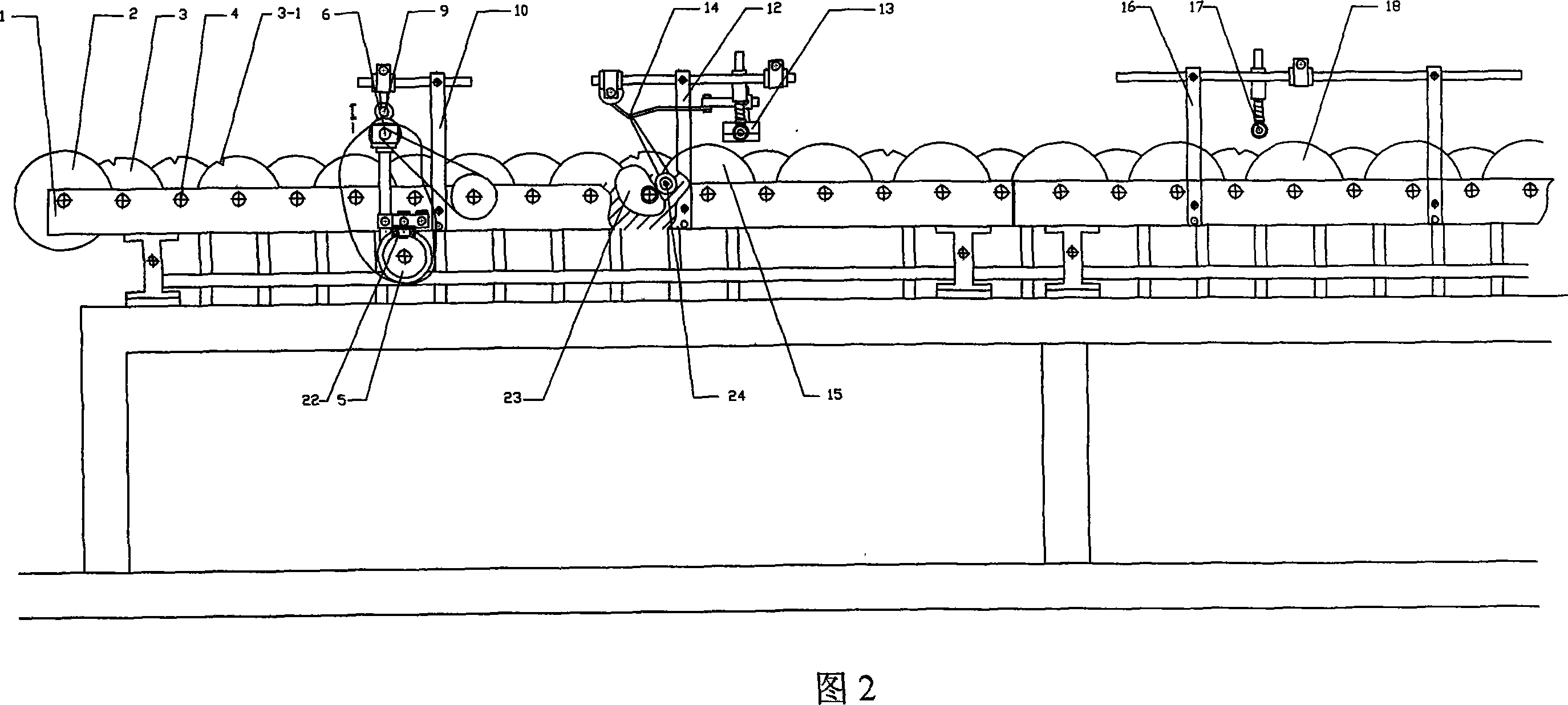

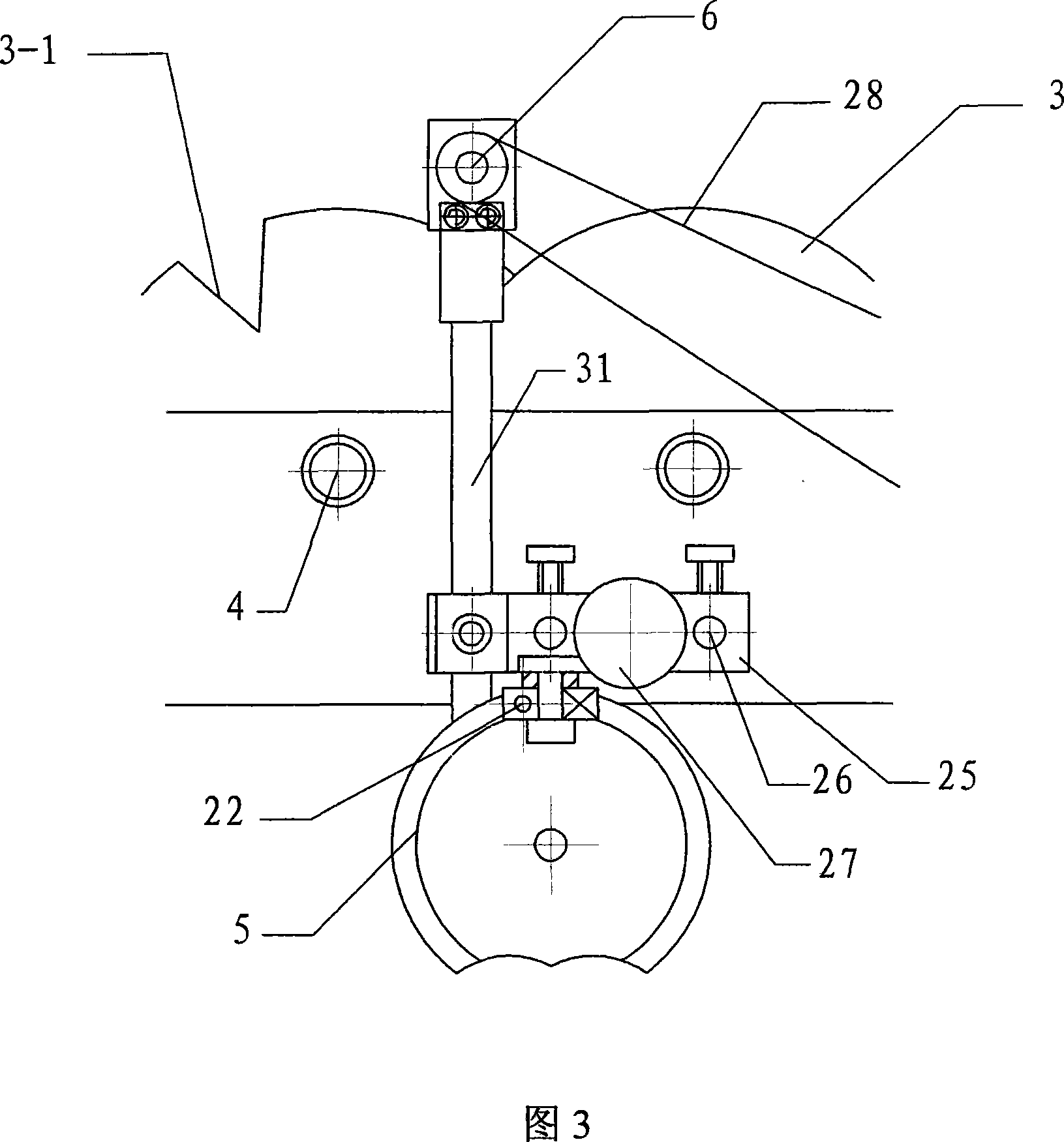

[0031] The production device includes: a frame 1, a transmission mechanism, a flaring mechanism, a bottom separating mechanism, a bottom sealing mechanism and a conveyor belt 21;

[0032] The transmission mechanism includes a motor and a transmission roller 4; several transmission rollers 4 are evenly distributed on the frame 1 through the shaft seat, and the motor is connected with the sprockets at both ends of each transmission roller 4 through a chain, so that each transmission roller 4 rotates synchronously; the transmission roller 4 A transmission disc 3 is mounted on the top, and a triangular slot 3-1 is provided on the periphery of the transmission disc 3 to drive the glass tube forward; in this way, the glass tube cannot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com